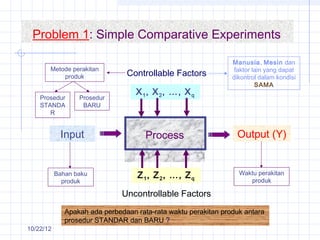

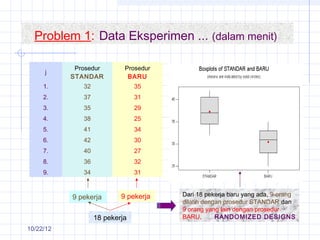

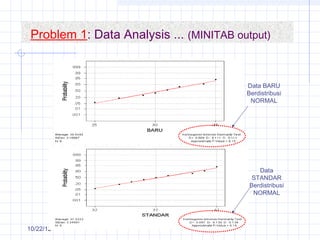

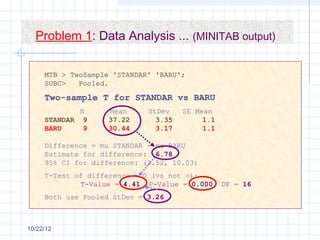

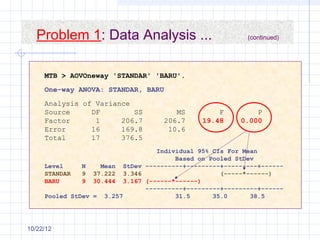

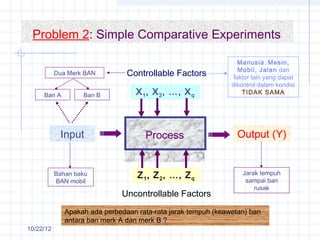

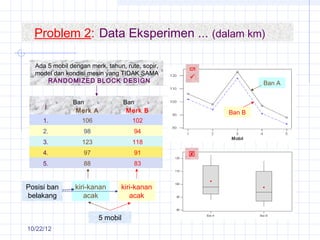

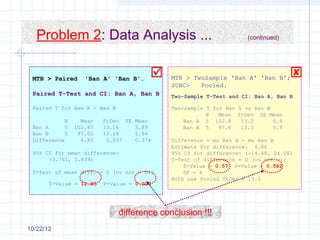

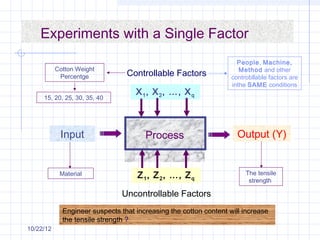

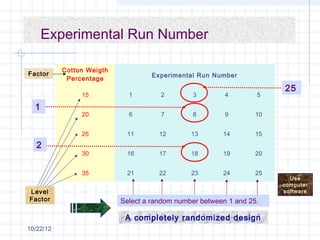

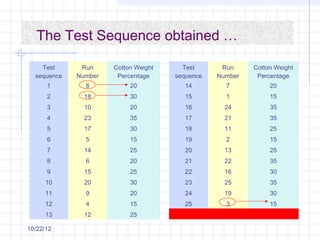

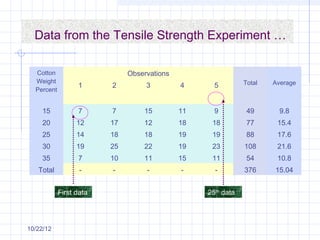

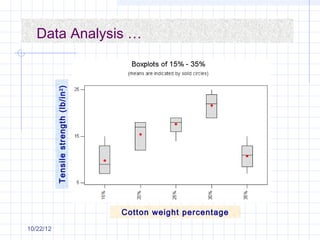

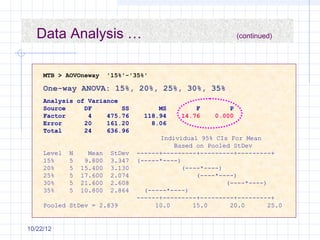

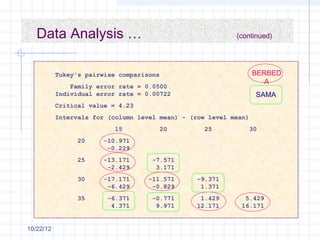

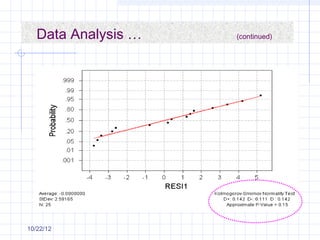

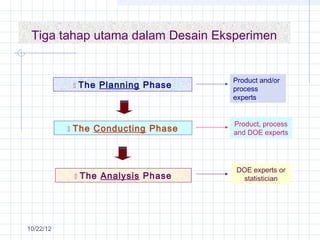

The document discusses different types of experimental designs, including simple comparative experiments, experiments with a single factor, randomized complete block design, Latin square design, and factorial designs. It provides examples of problems involving comparative experiments between two production procedures and between two tire brands. It demonstrates the process of collecting data, performing statistical analyses like t-tests, ANOVA, and Tukey's test to analyze the results and determine if there are significant differences between groups. The key steps in experimental design are planning, conducting, and analysis phases.