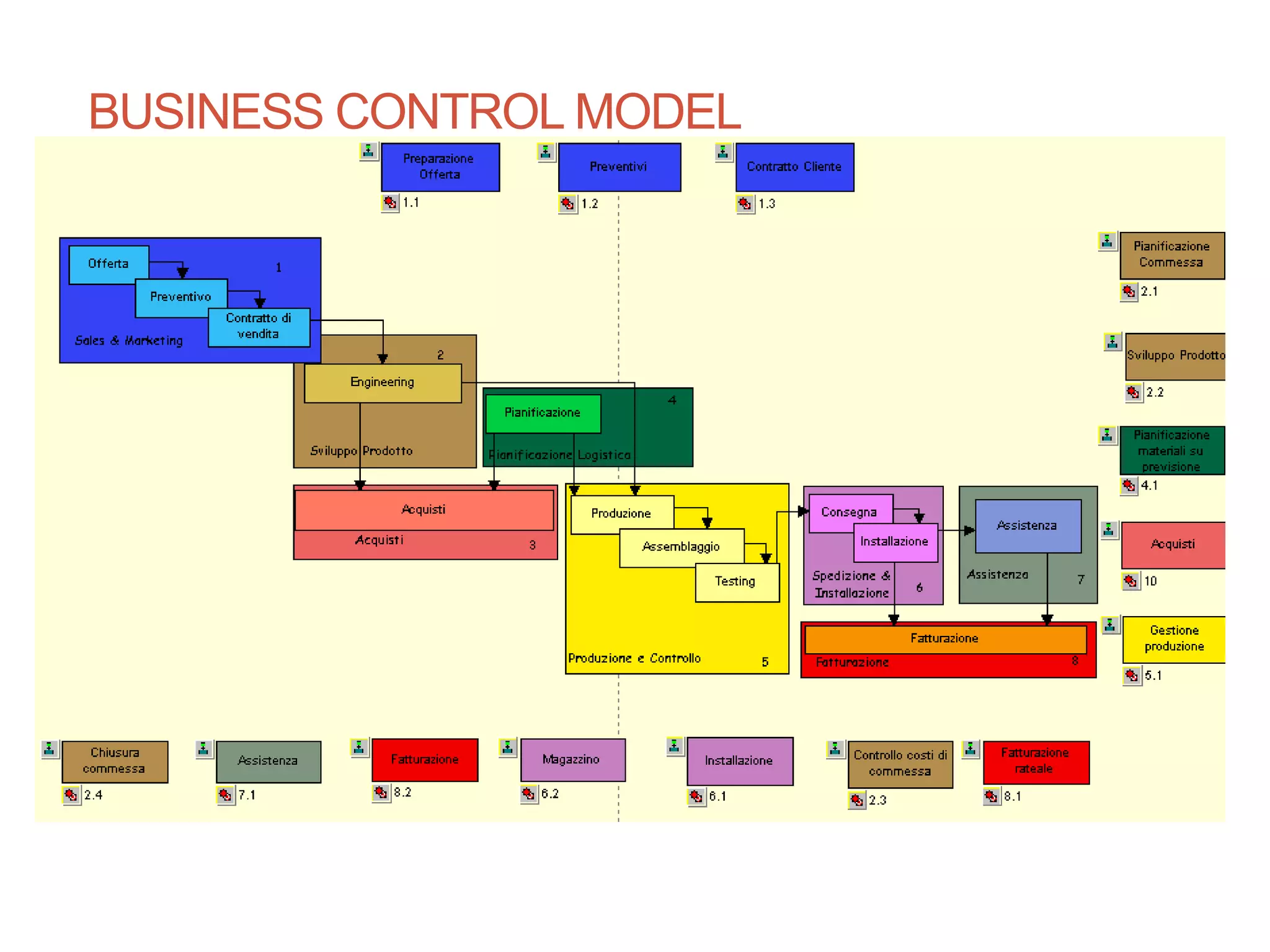

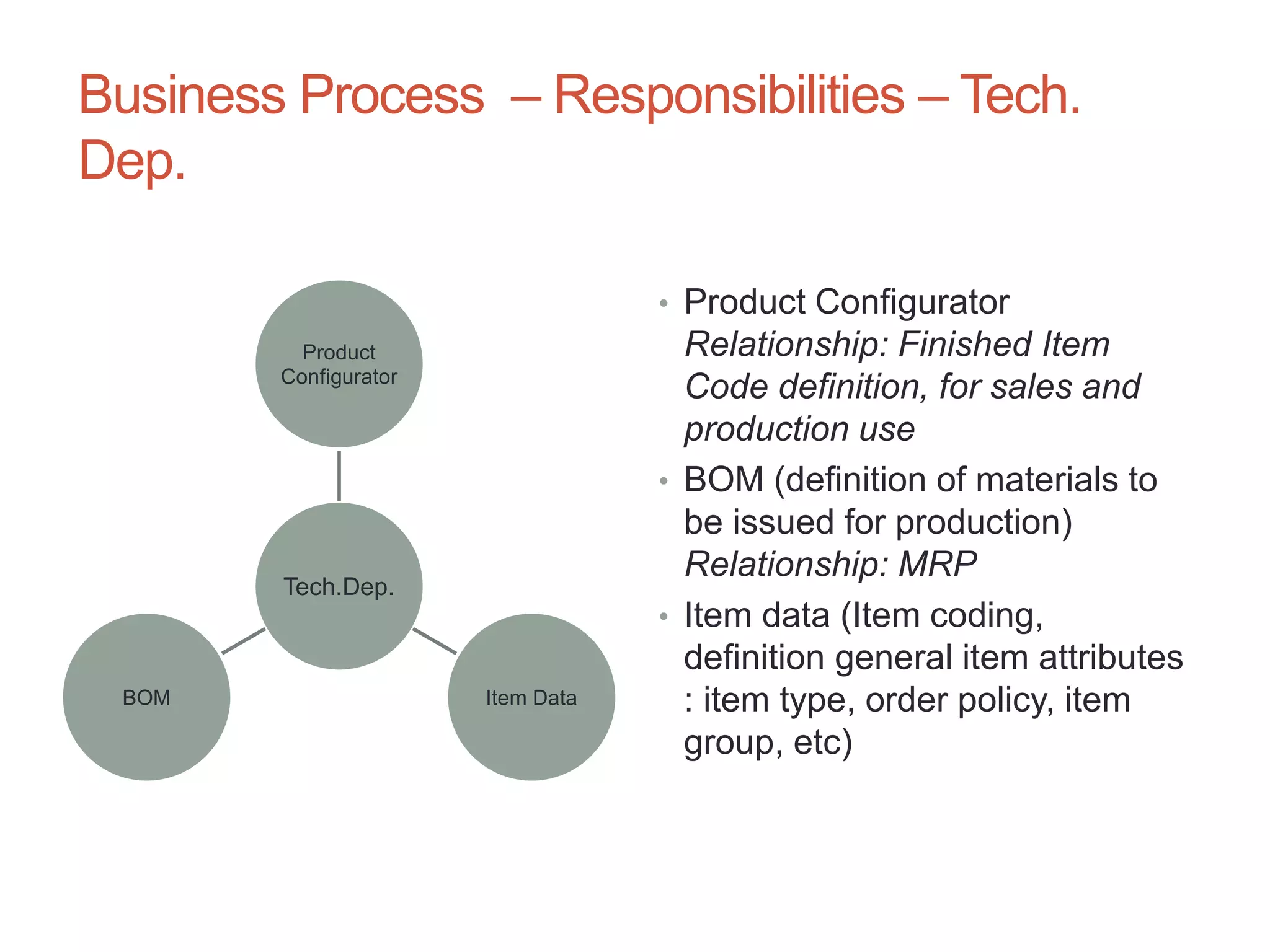

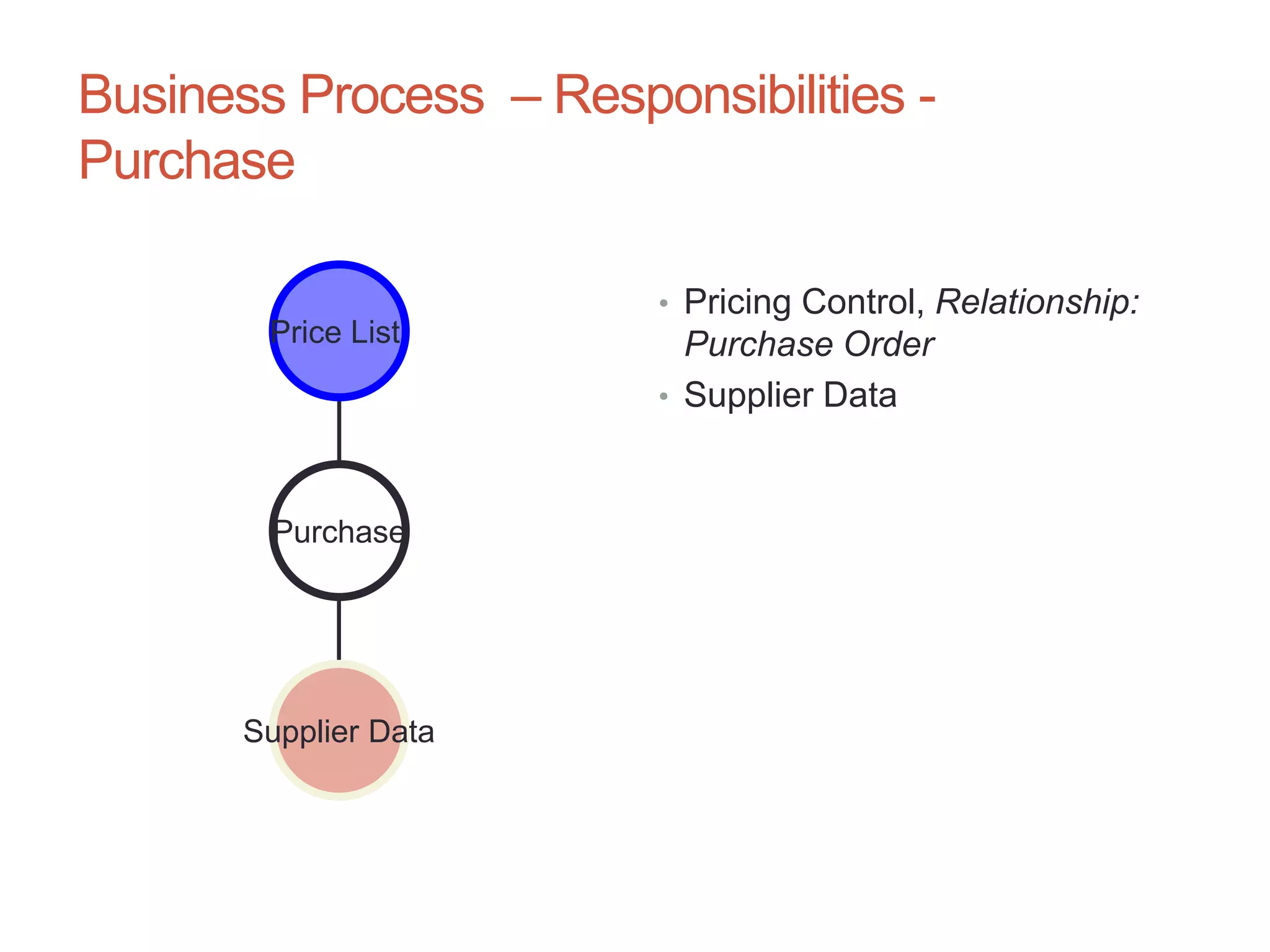

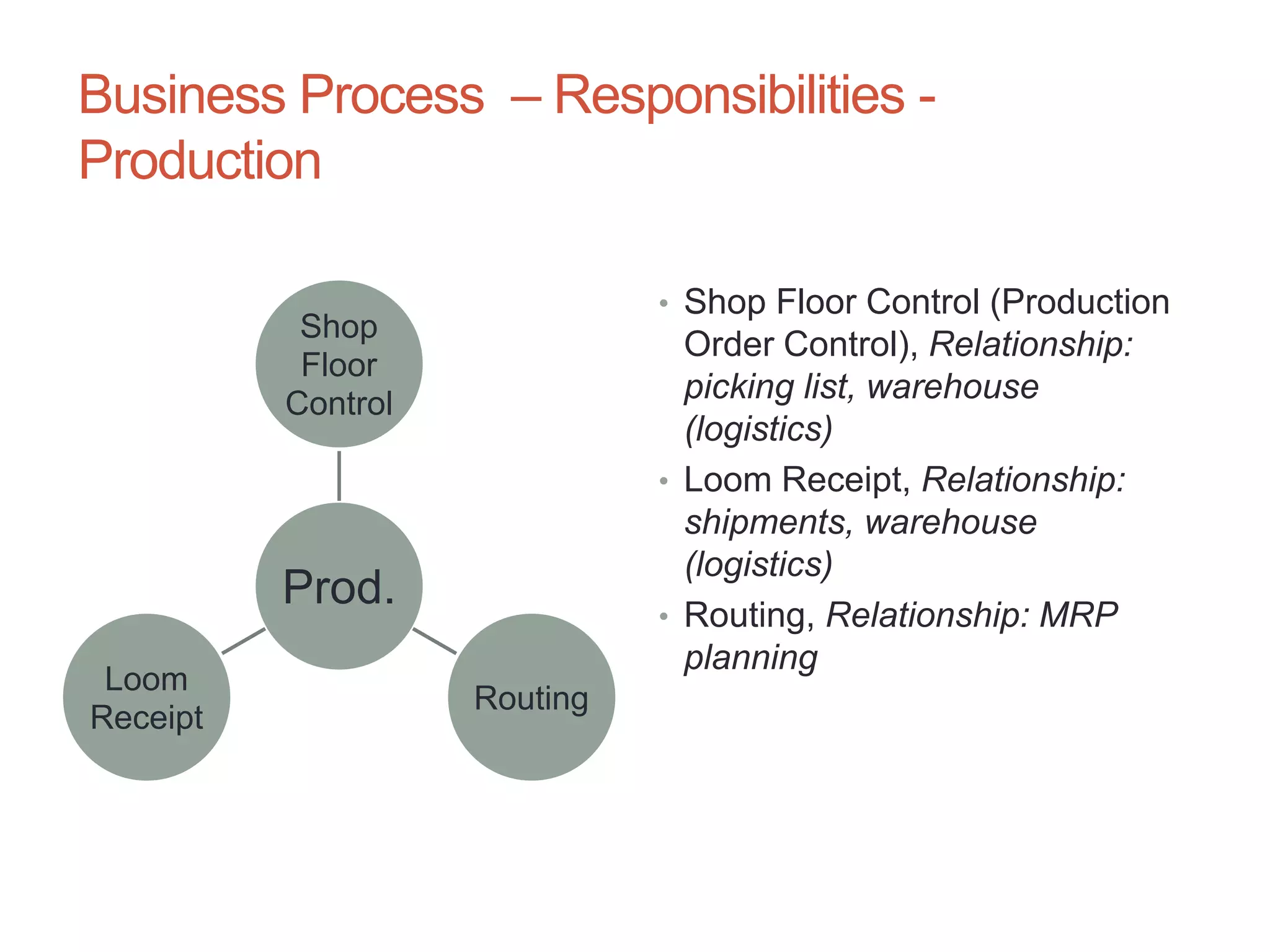

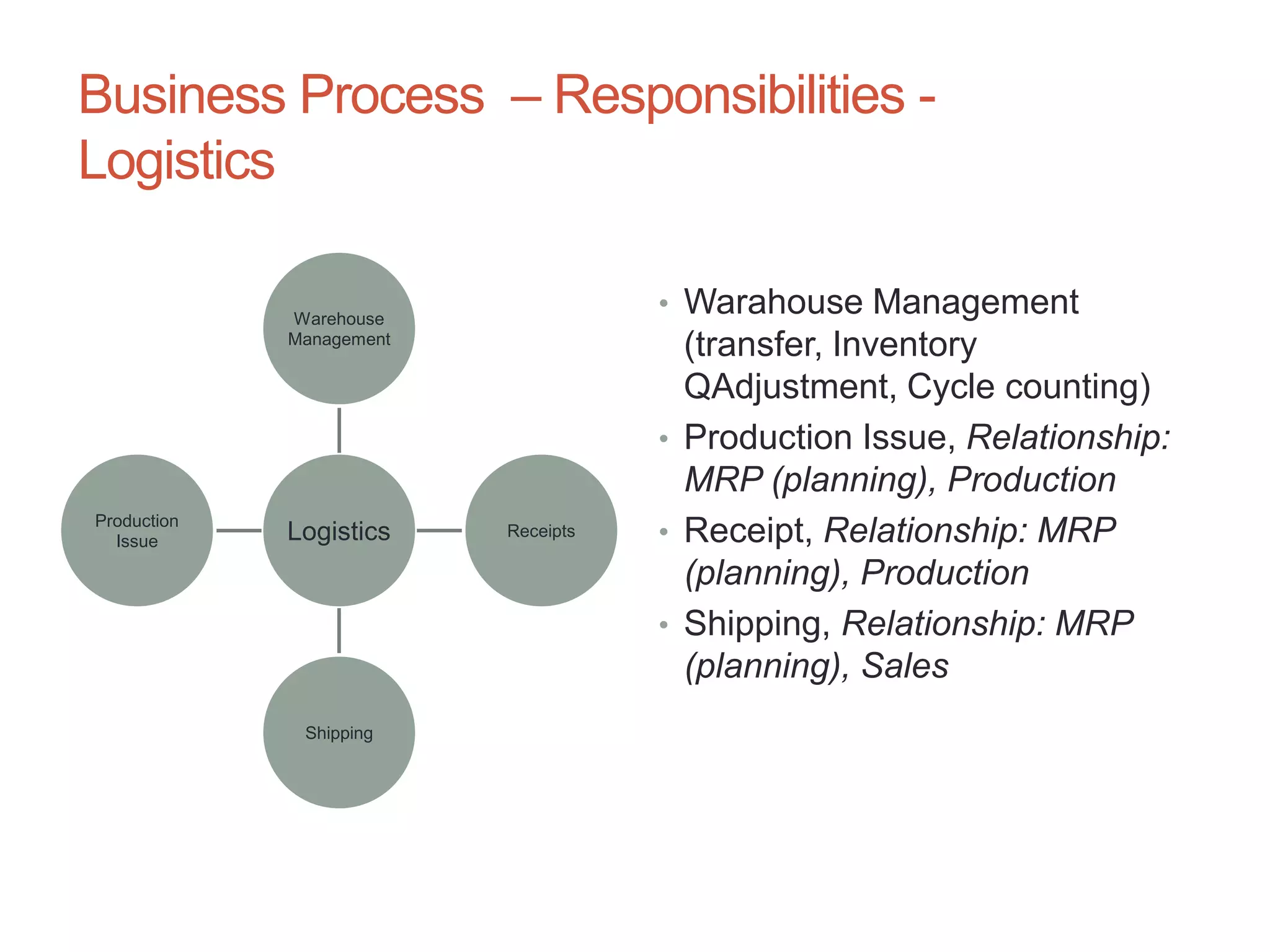

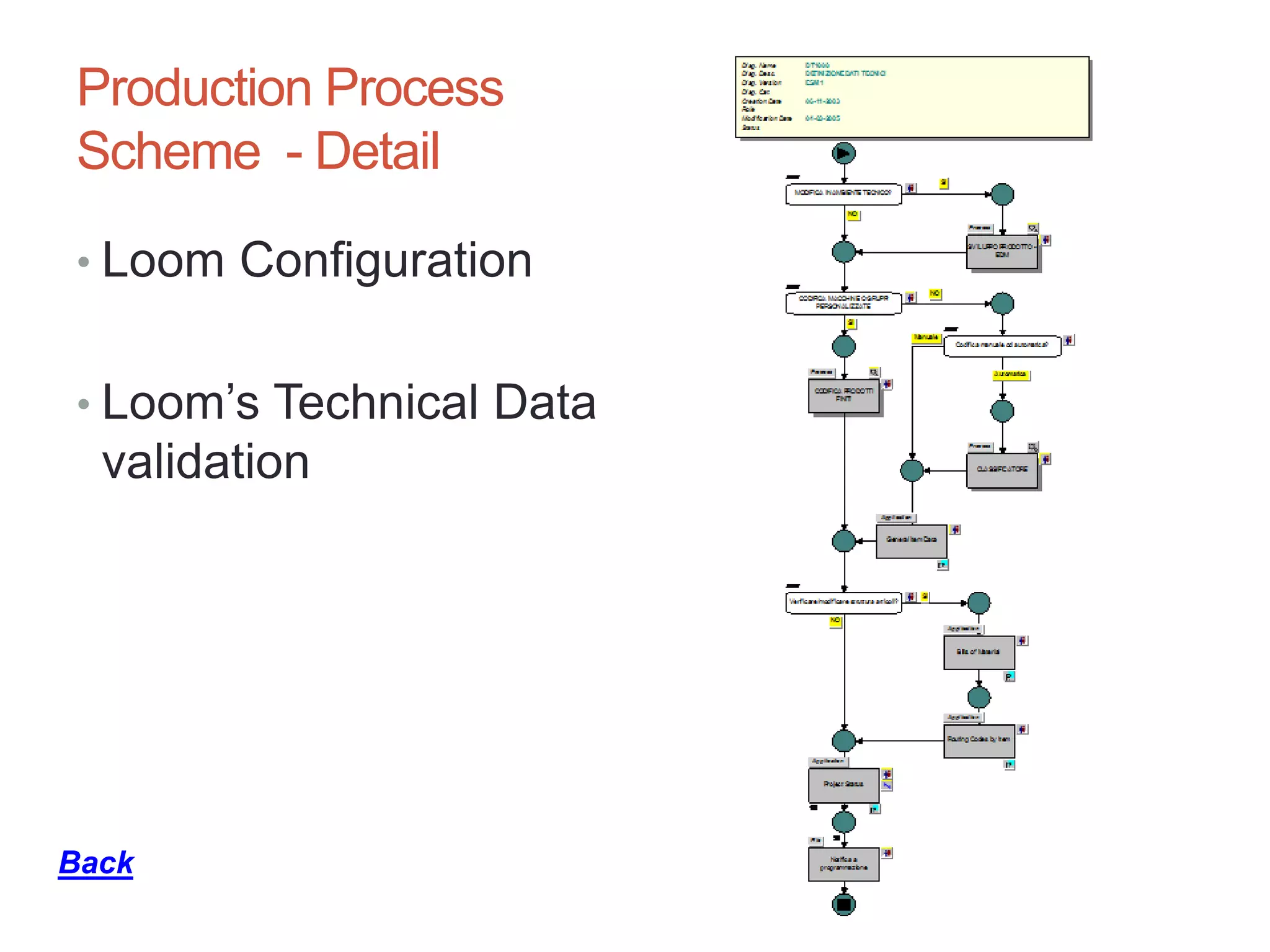

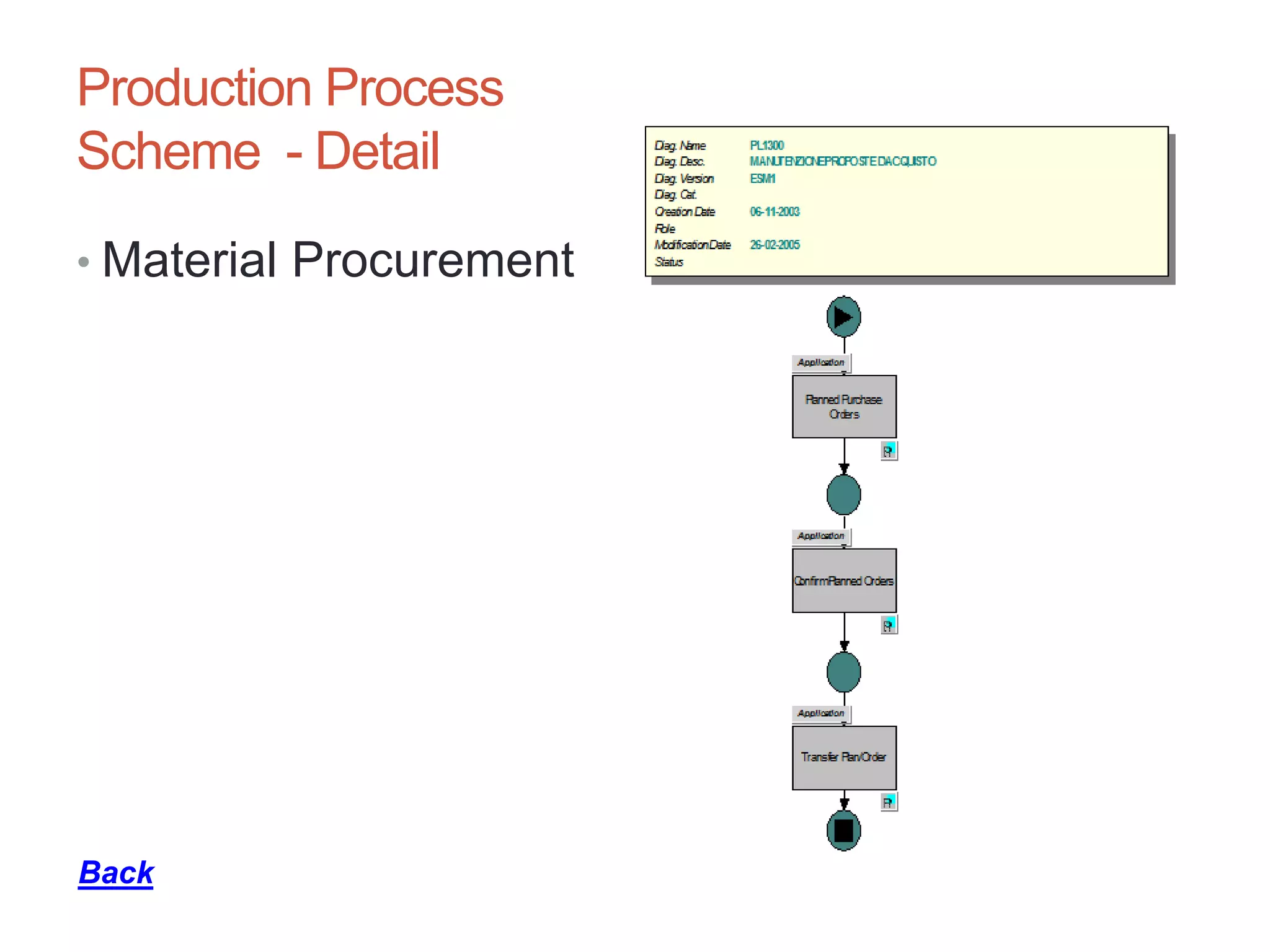

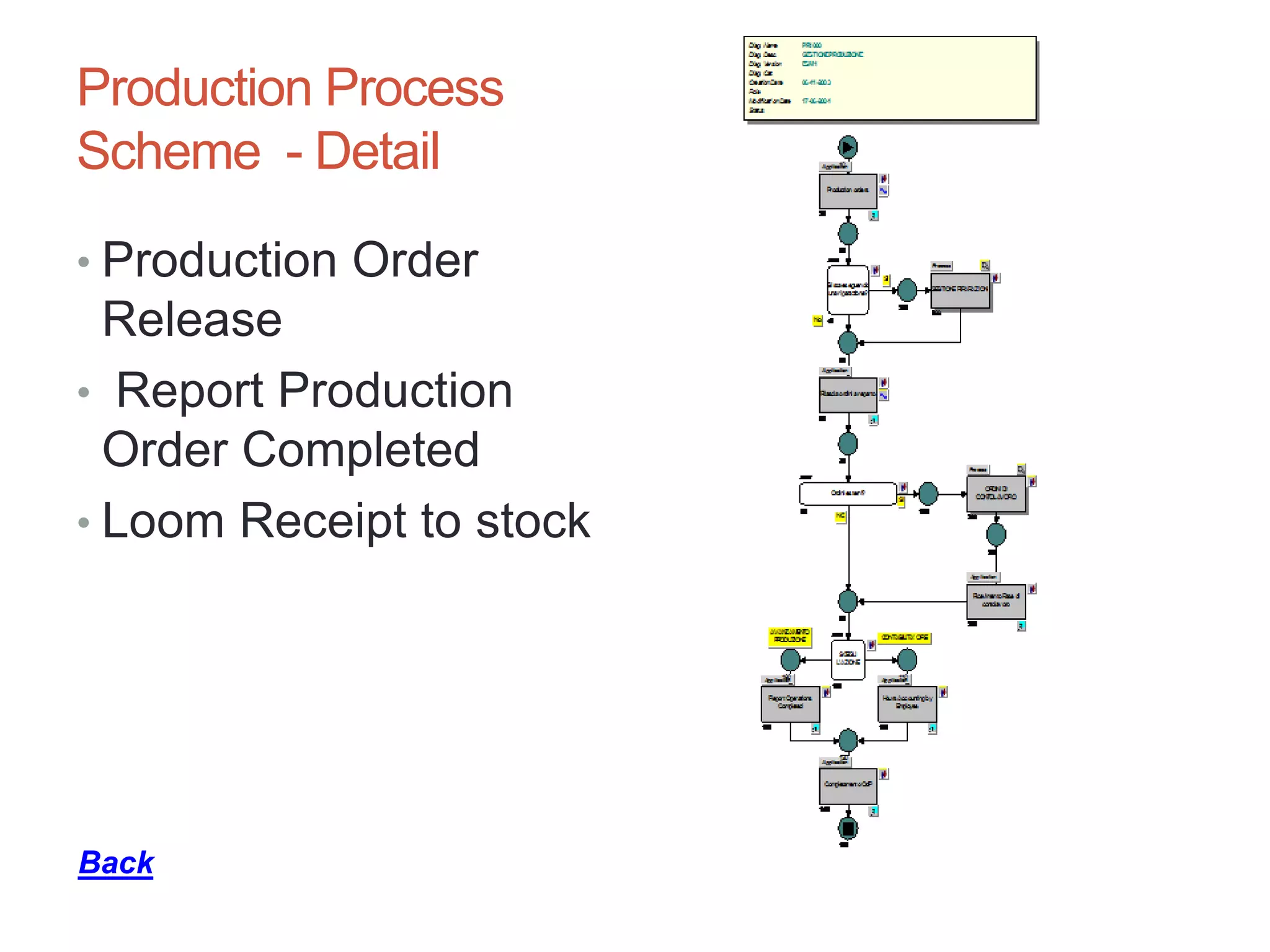

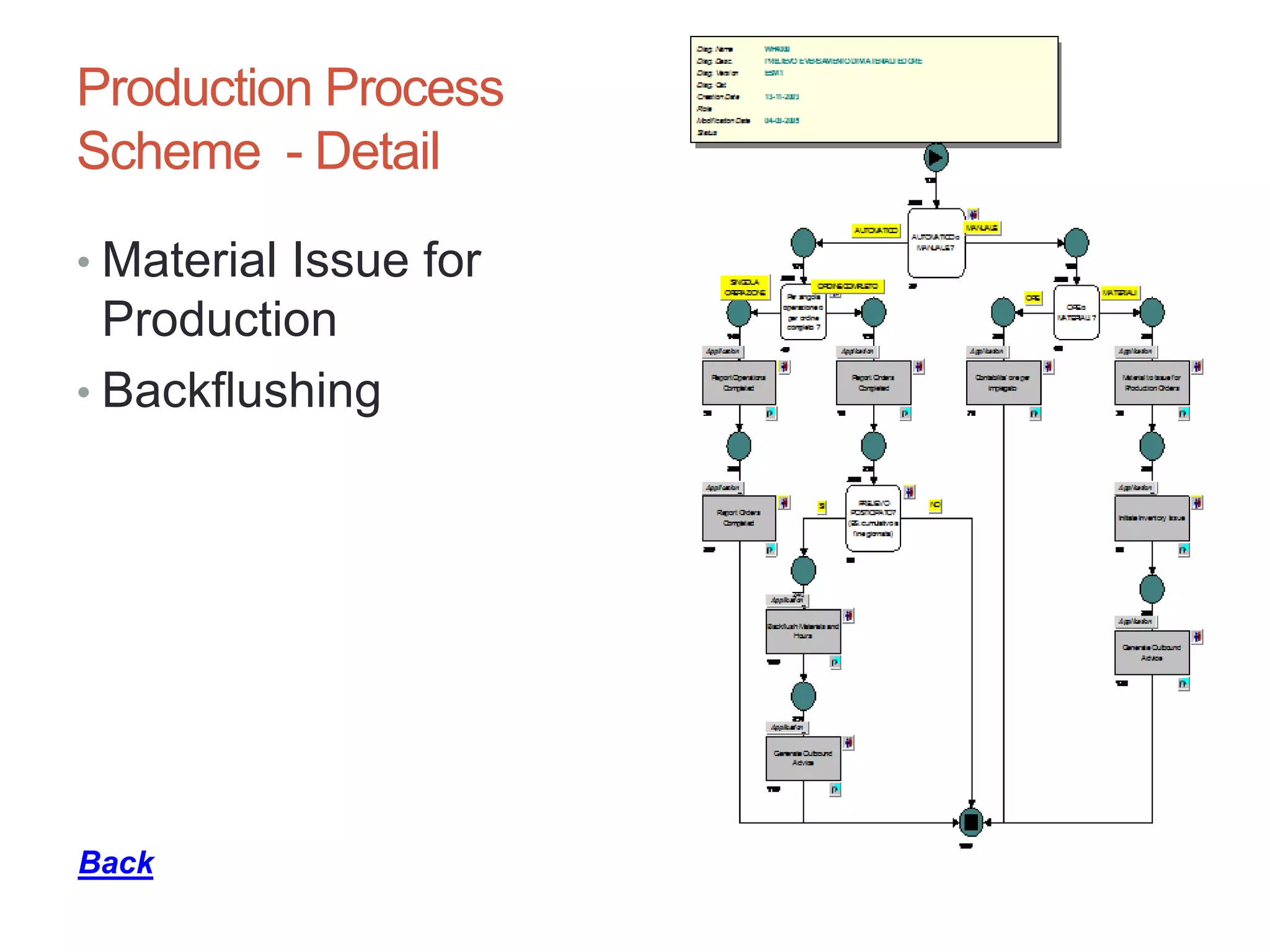

This document outlines the key business processes and responsibilities across a company's operations. It details the relationships between customer data, sales order management, material planning, procurement, production processes like routing and shop floor control, logistics like warehousing and shipping, and supporting functions like product configuration and bill of materials definition. The production process scheme is broken down into steps from loom configuration to finished goods shipment.