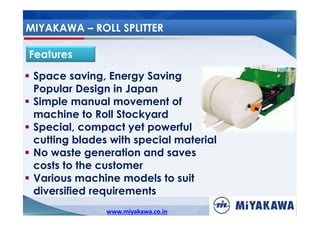

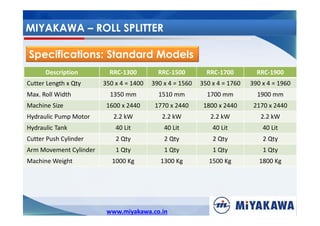

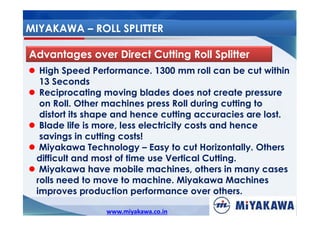

Miyakawa Industries is a Japanese company established in 1953 that is a leader in multi-spindle attachments, drilling machines, and high-speed paper roll cutting machines. The document focuses on Miyakawa's roll splitter machines, which can cut rolls up to 1,300 mm in diameter within 15 seconds using a patented reciprocating blade movement that allows for smooth, fast, and precise cuts without distorting the roll shape. The mobile roll splitter machines have various models and specifications to suit diverse paper cutting needs.