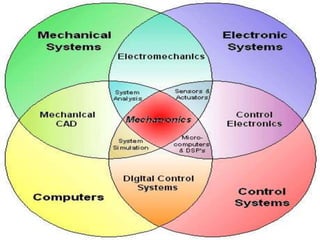

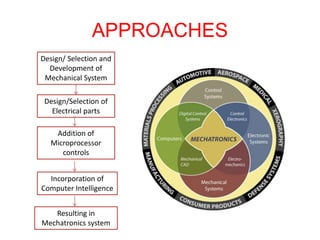

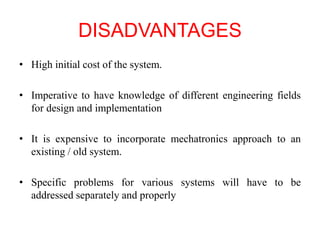

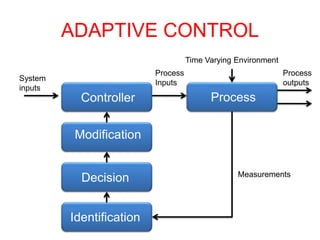

This document discusses mechatronics, including its origin and evolution since 1969, definitions from various sources, common approaches, interdisciplinary scenarios, needs, advantages, disadvantages, and applications. It originated as the combination of mechanics and electronics at a Japanese company in 1969. Mechatronics involves the synergistic integration of mechanical engineering, electronics, and computer control in designing industrial products and processes. Some examples of mechatronics applications mentioned include engine management systems, washing machines, weighing scales, and adaptive control systems.

![DEFINITION

• The word mechatronics is composed of “Mecha” from mechanics and the

“Tronics” from electronics - YASUKAWA ELECTRIC COMPANY

• The synergistic integration of mechanical engineering, with electronics and

intelligent computer control in the design and manufacturing of industrial

products and processes.

-HARASHIMA, TOMIZUKA, FUKADA

[1996]

• Mechatronics is the application of complex decision making to the

operation of physical systems

-AUSLANDER & KEMPF [1996]

• Mechatronics is a methodology used for the optimal design of electro

mechanical products.

- SHETTY & KOLK [1997]

• A mechatronic system is not just a marriage of electrical and mechanical

systems and is more than just a control system; it is a complete integration](https://image.slidesharecdn.com/1mechatronics-230811012805-cf4803c0/85/Mechatronics-pptx-3-320.jpg)