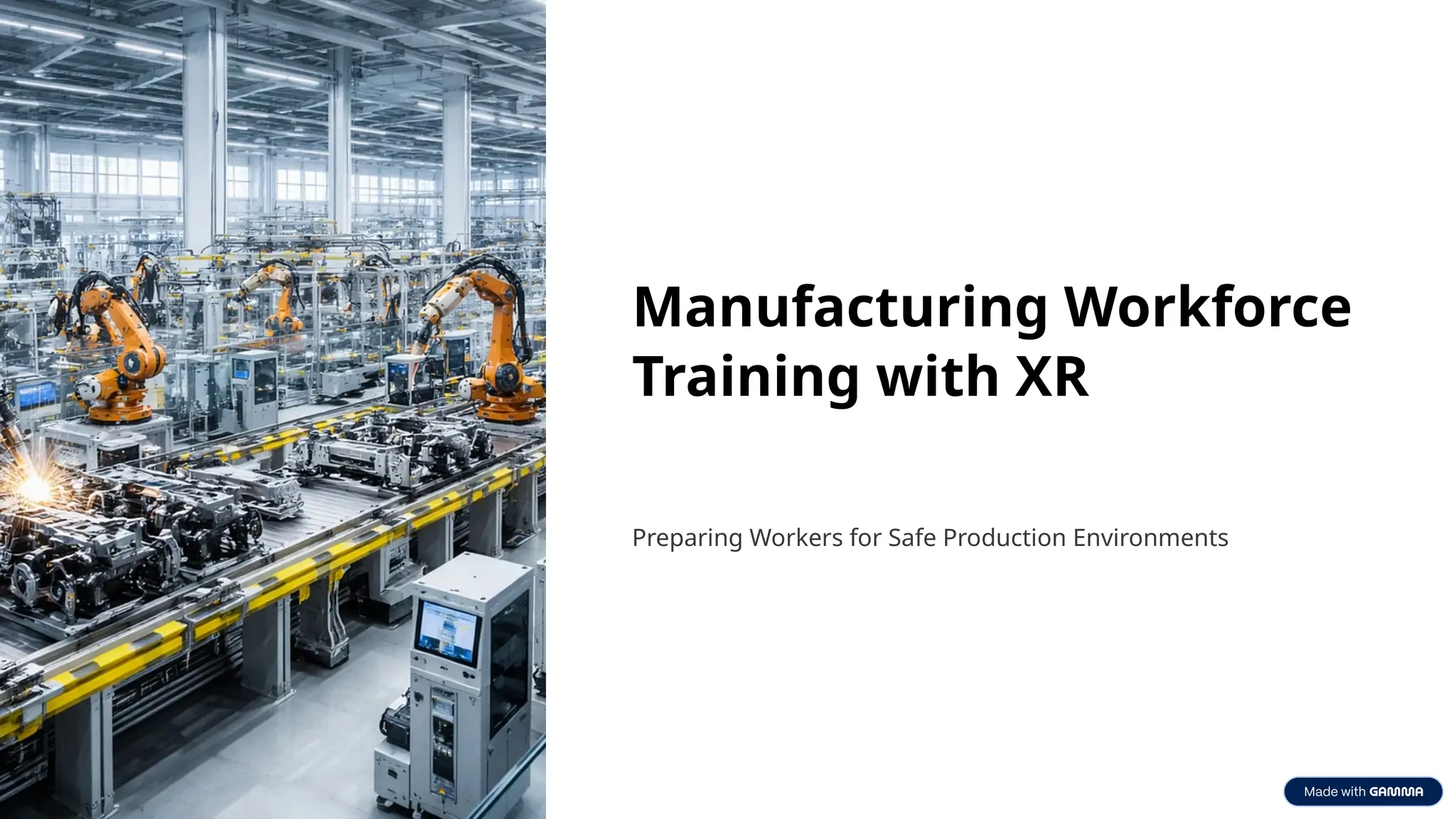

This presentation explores how manufacturing workforce training is evolving to better prepare teams for complex, safety-critical production environments. It outlines common training challenges, the role of experience-based preparation, and how immersive learning environments can support operational readiness before live production begins.

👉 Explore the full page to learn more:https://radiumxr.com/manufacturing-industrial-xr-training