Manual handling of batteries poses risks to workers' backs that must be properly managed:

1) Lifting batteries unaided can cause back damage if the weight and height are inappropriate for the individual.

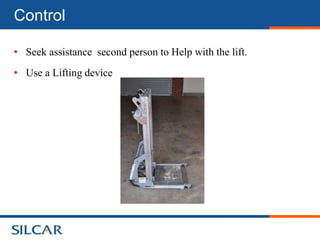

2) Workers should assess if an item can be safely lifted alone or requires assistance from a second person or lifting device.

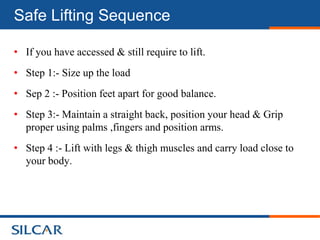

3) When lifting batteries, workers should position their feet, maintain a straight back, and lift with their legs to avoid straining their back. Seeking help for heavy loads is important for safety.