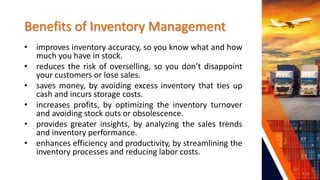

The document provides an overview of key concepts in logistics management. It defines logistics management and discusses related concepts like transportation, warehousing, inventory management, packaging, and control/communication. Logistics management aims to coordinate activities like procurement, manufacturing, and distribution to meet customer demands efficiently. It involves planning and optimizing the flow of goods and information.