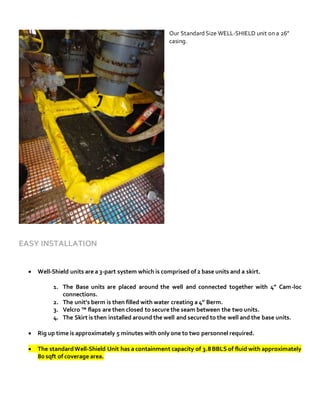

This document describes spill containment systems called Well-Shield and Site-Shield units. The units are made of durable, waterproof vinyl-coated polyester fabric and coated with polyurethane and rubber for strength and safety. Well-Shield units are comprised of connecting base units that form a berm when filled with water, and a skirt that secures around the well. They contain spills of up to 3.8 barrels and install in about 5 minutes with 1-2 people. Site-Shield units provide containment for work areas. The document provides contact information for more product details.