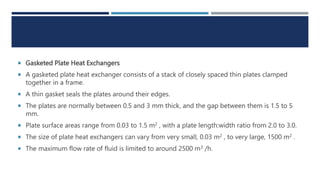

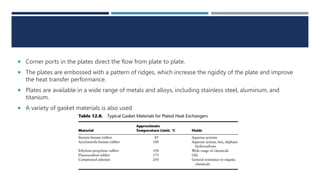

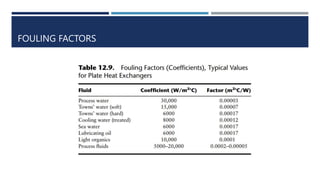

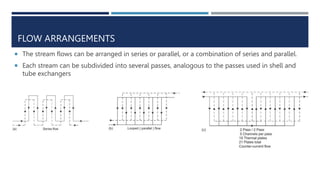

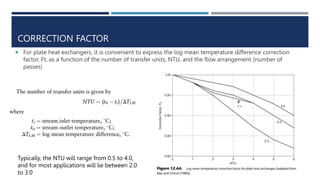

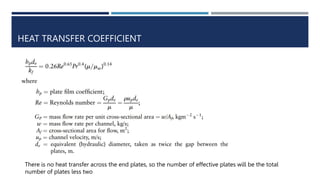

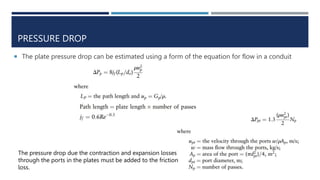

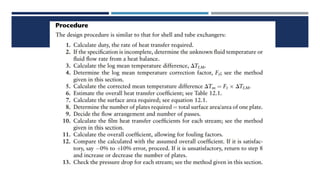

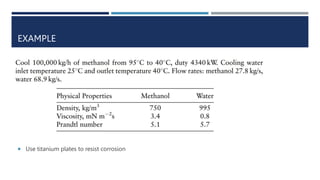

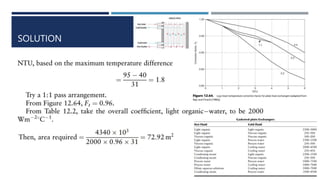

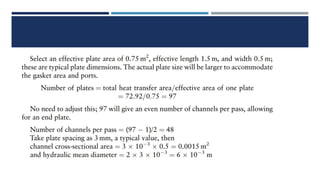

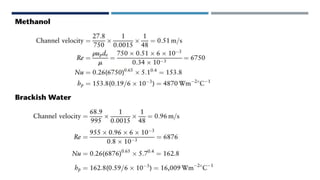

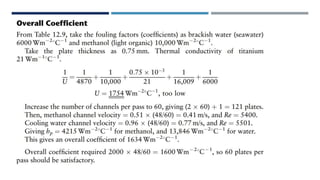

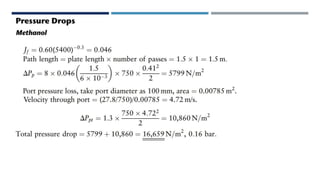

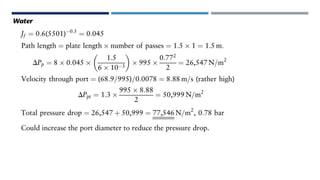

This document provides an overview of plate heat exchangers. It describes the basic components and design of a plate heat exchanger, including thin metal plates separated by gaskets that are clamped together in a frame. Fluid flows between the plates in parallel paths directed by corner ports. The plates have embossed ridges to improve heat transfer. Plate materials include stainless steel, aluminum, and titanium. Applications include food/beverage processing where they can be easily disassembled for cleaning. The document also discusses factors like fouling, flow arrangements, heat transfer coefficients, and pressure drops in plate heat exchanger design and examples.