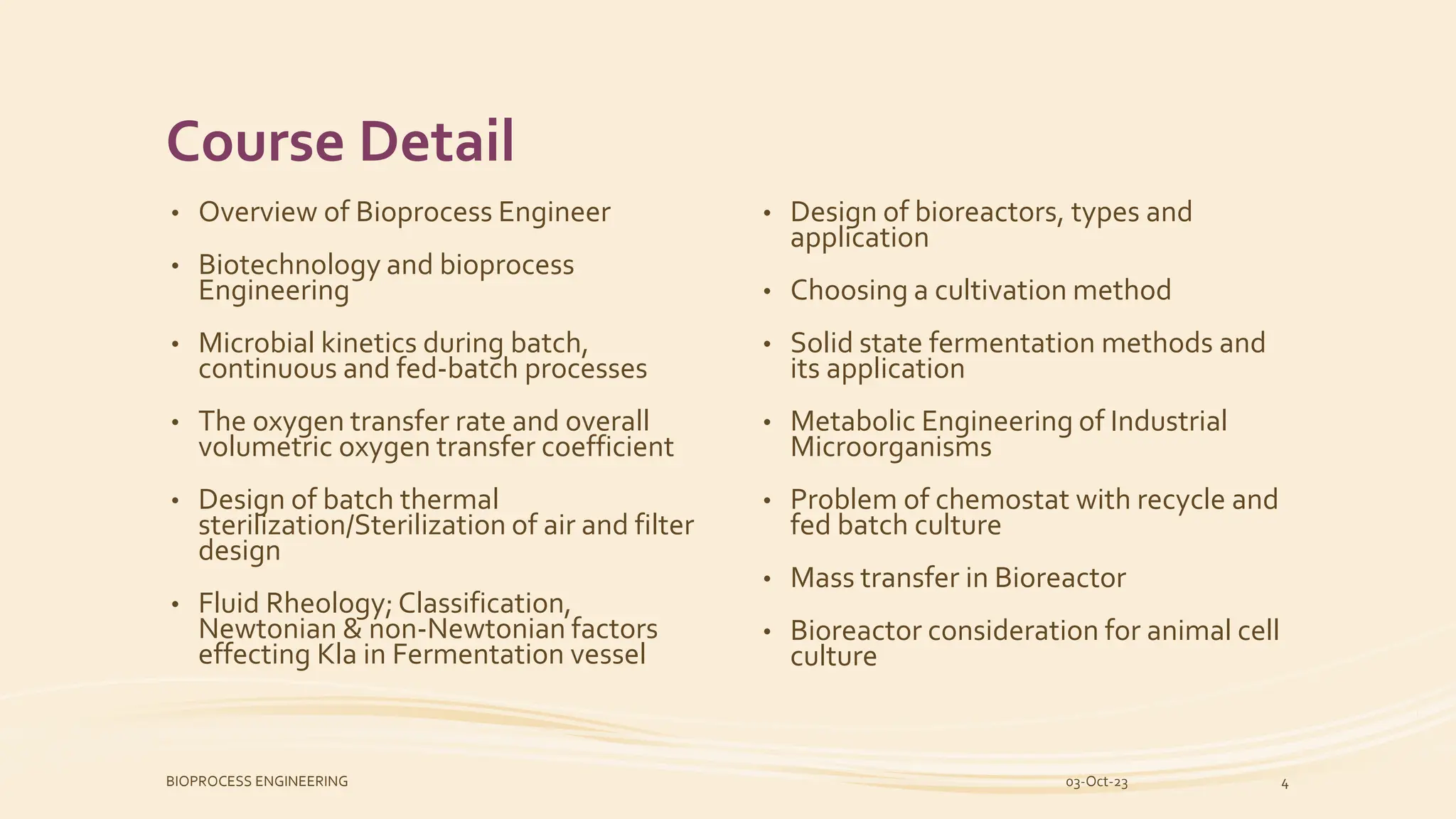

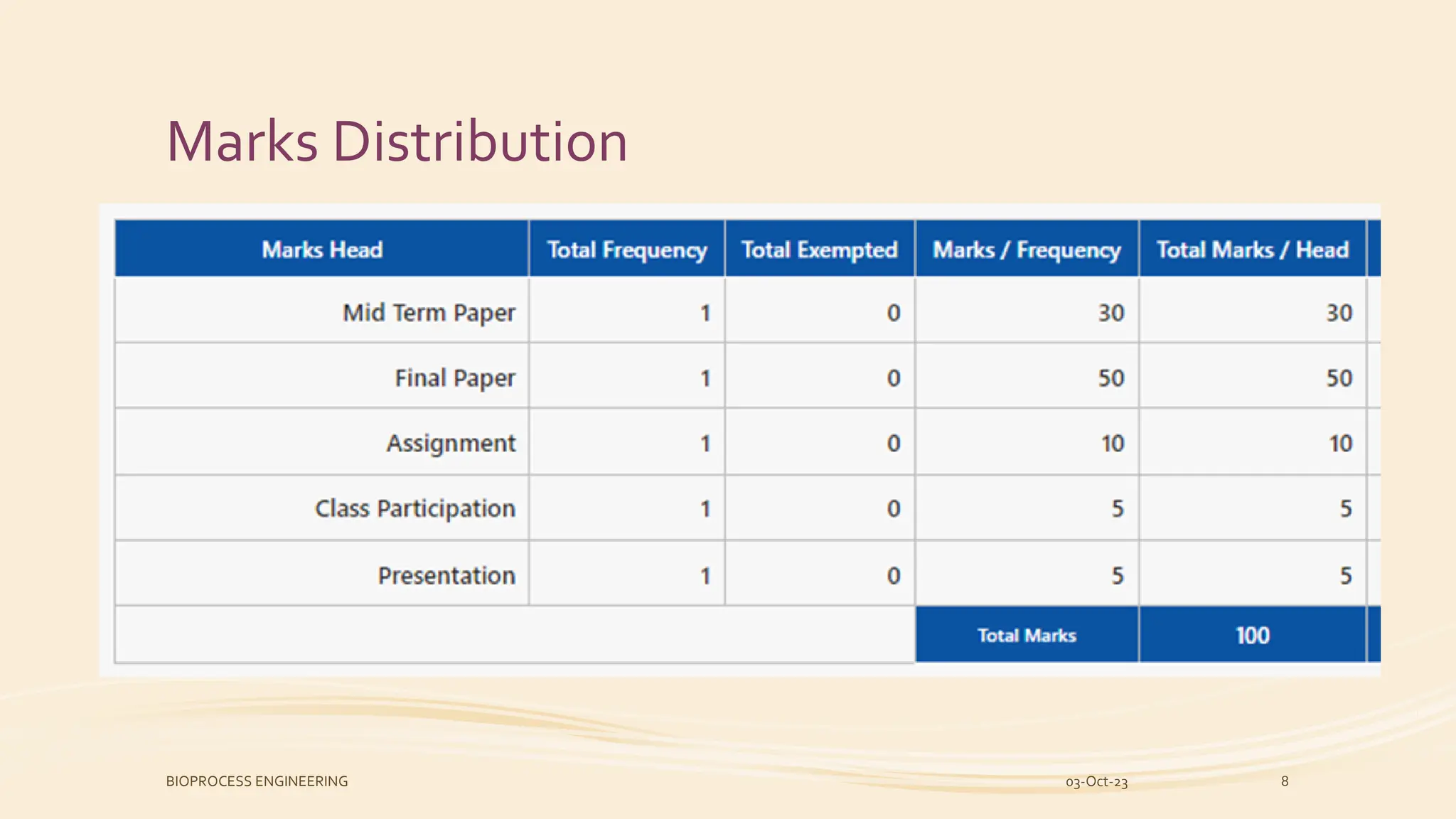

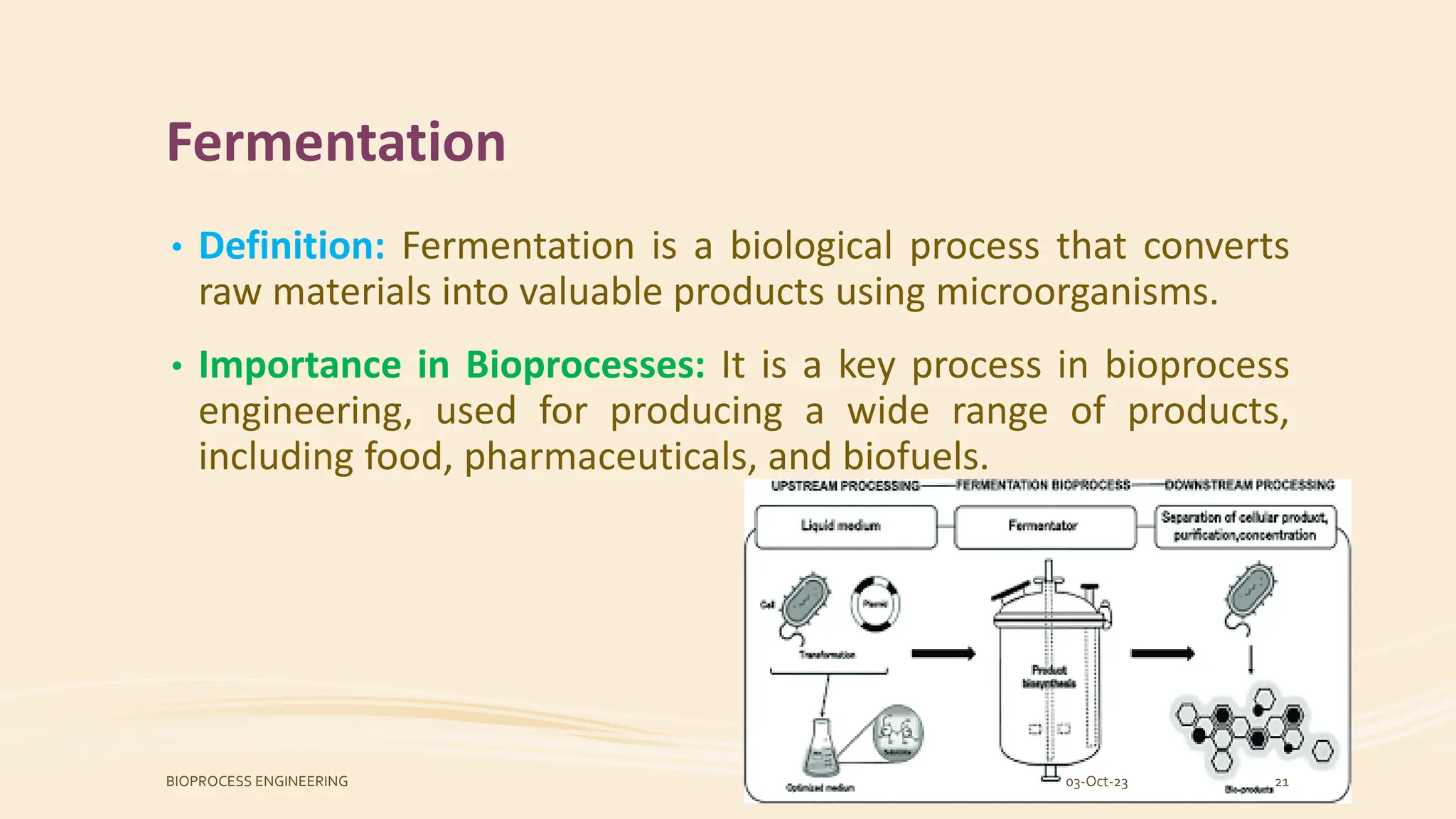

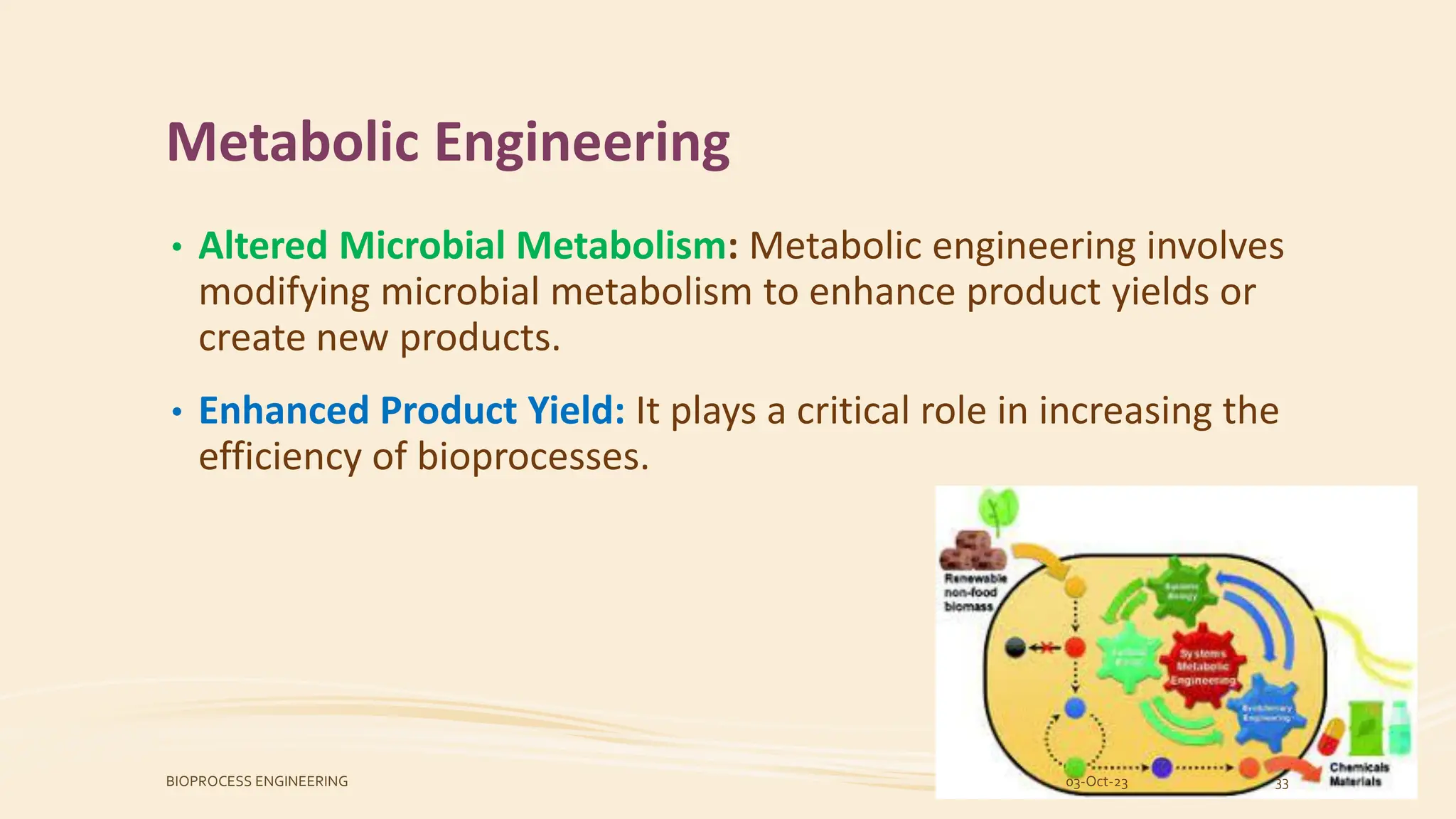

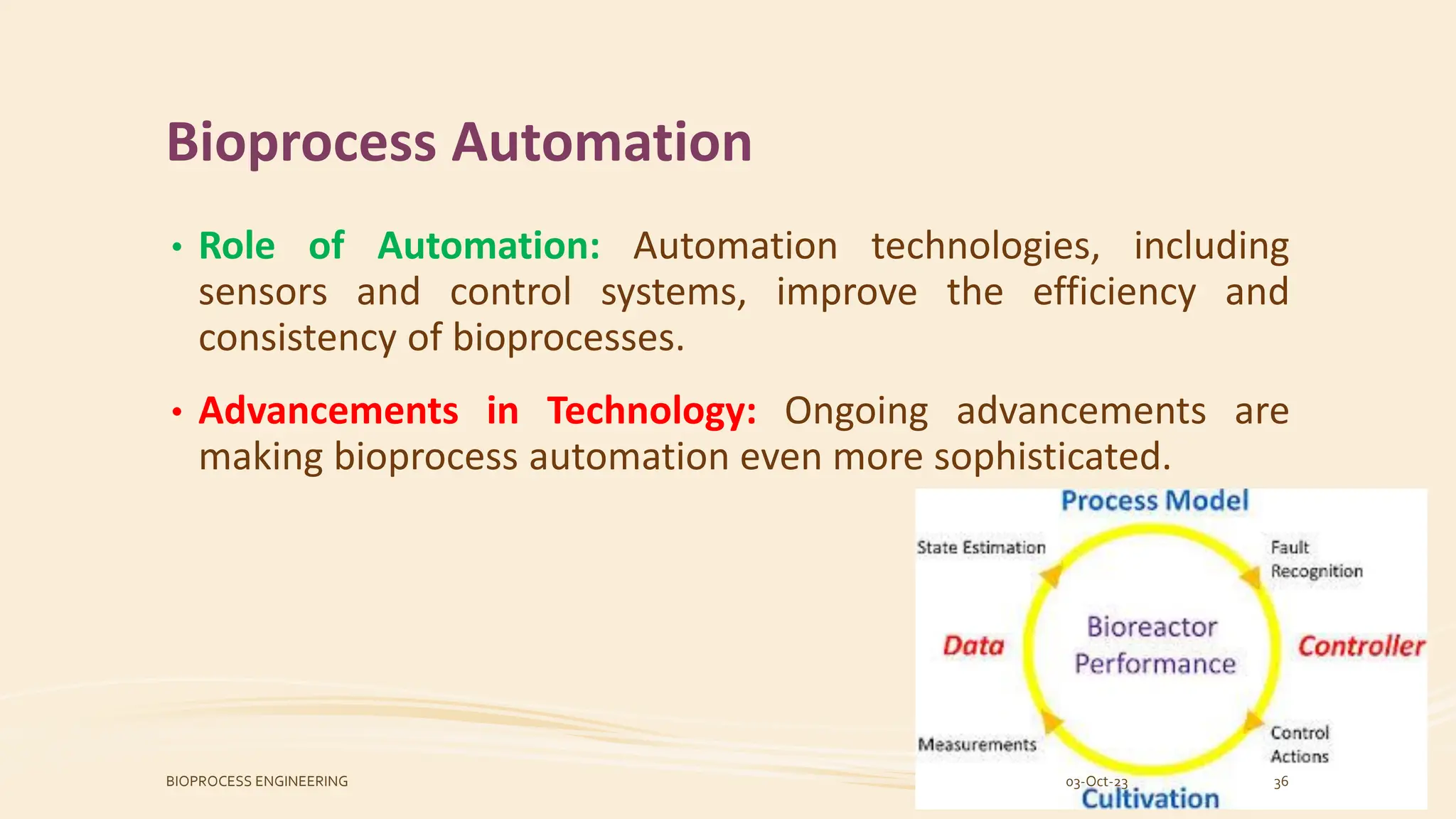

The document outlines the course details for a Bioprocess Engineering course. It includes the course code, title, credit hours, and schedule. It provides an overview of the topics that will be covered in the course, such as bioreactors, fermentation, downstream processing, and metabolic engineering. It also lists the recommended textbooks and describes how students will be evaluated, including assignments, presentations, and class participation.