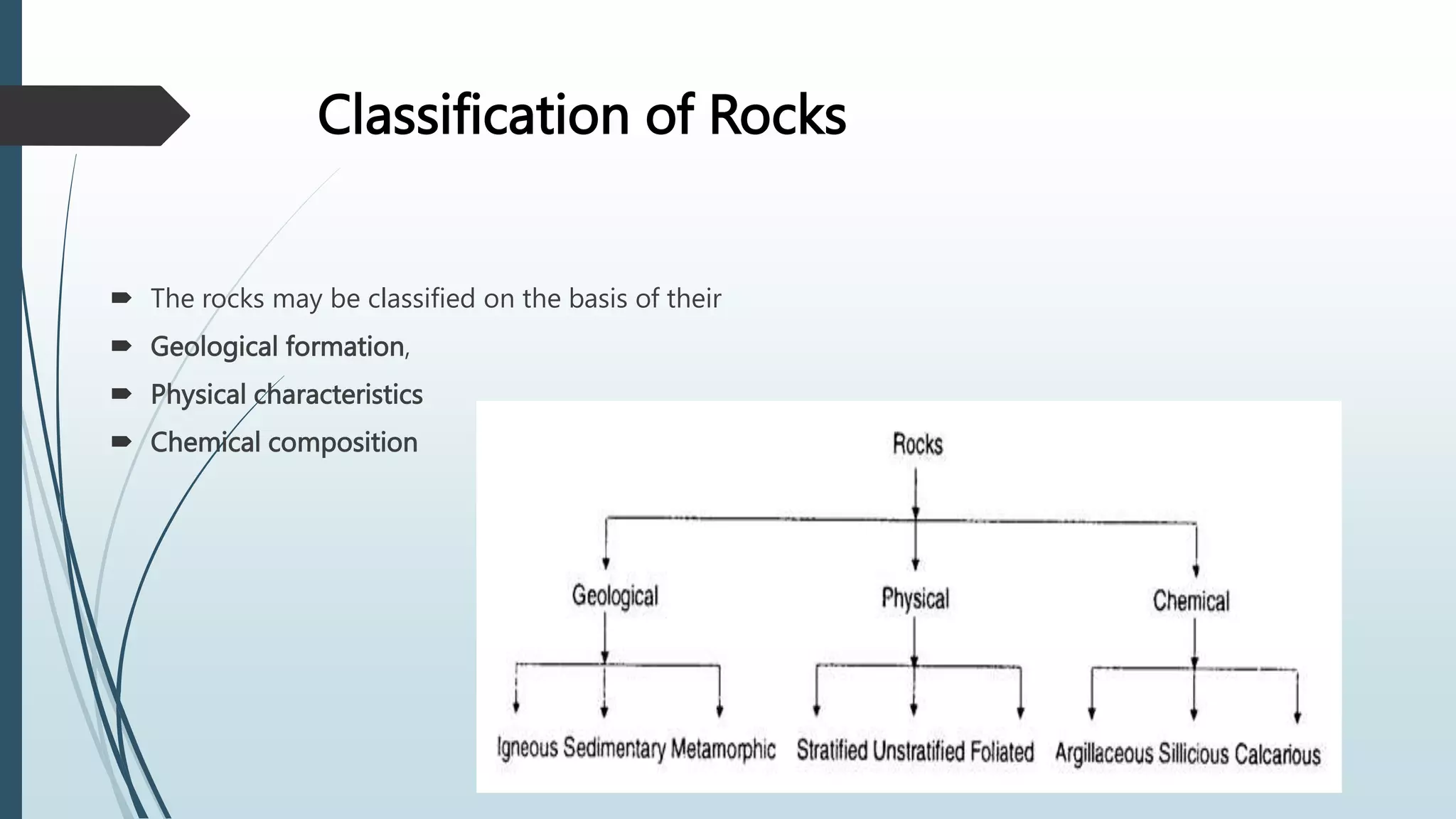

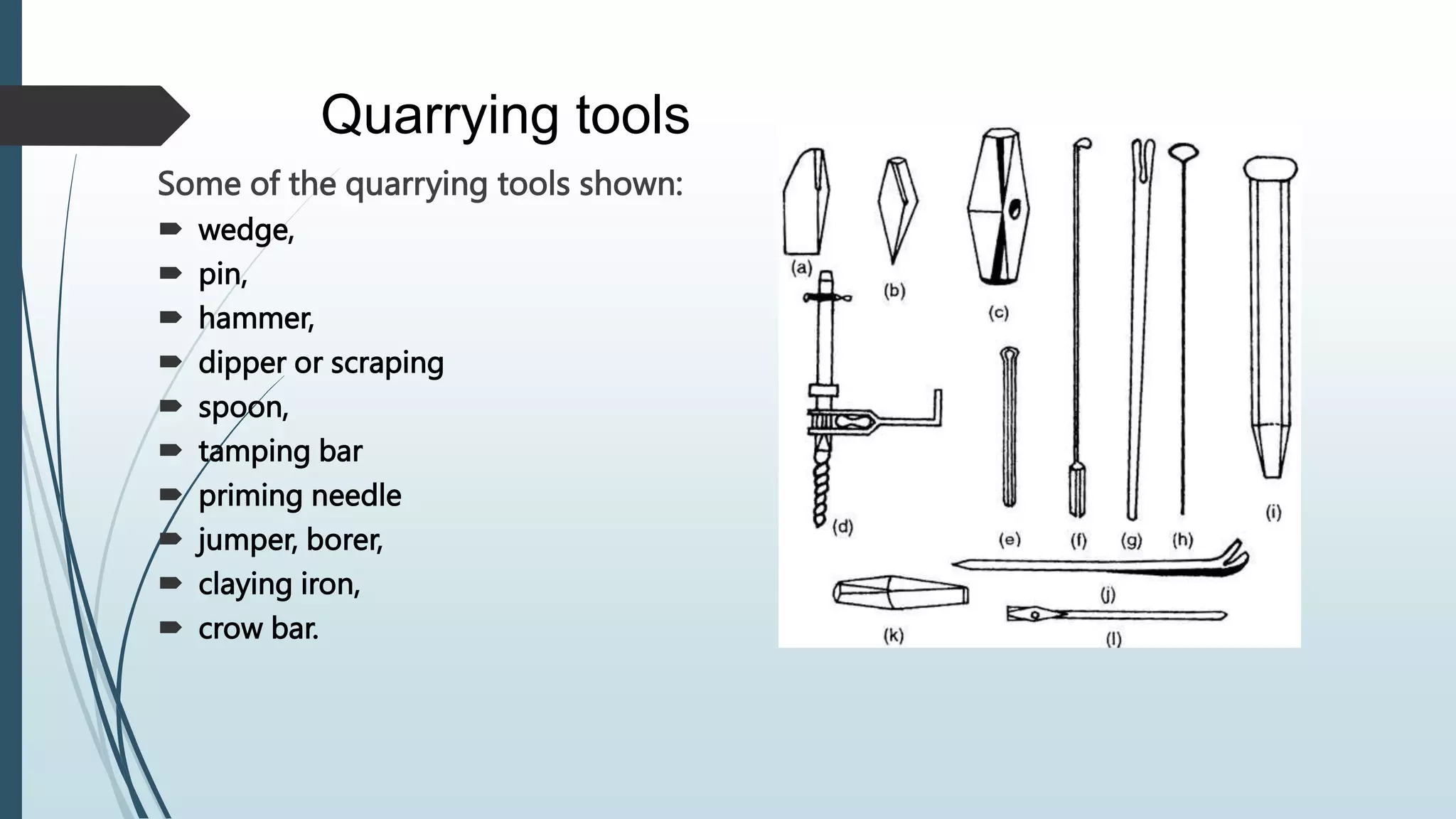

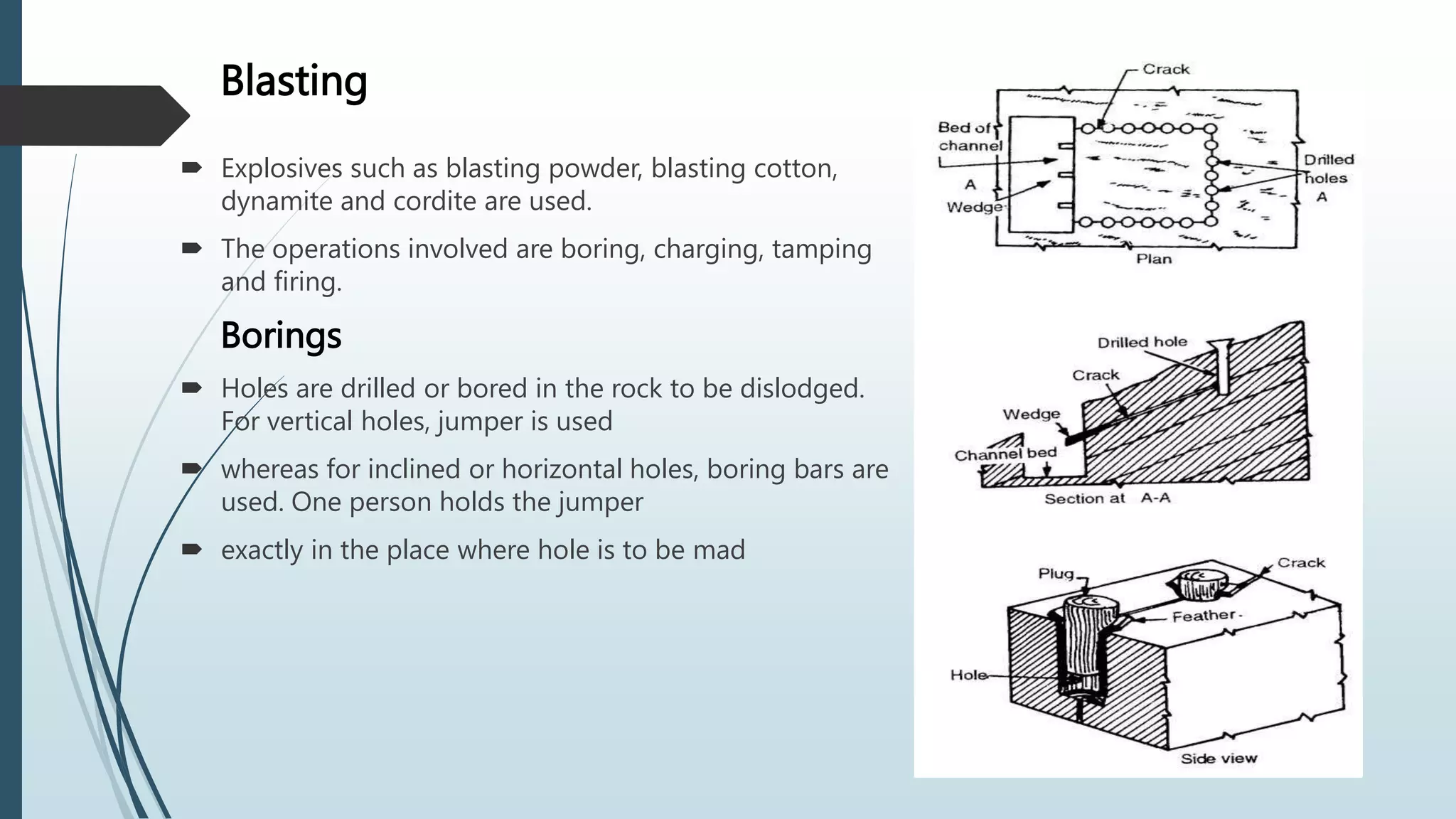

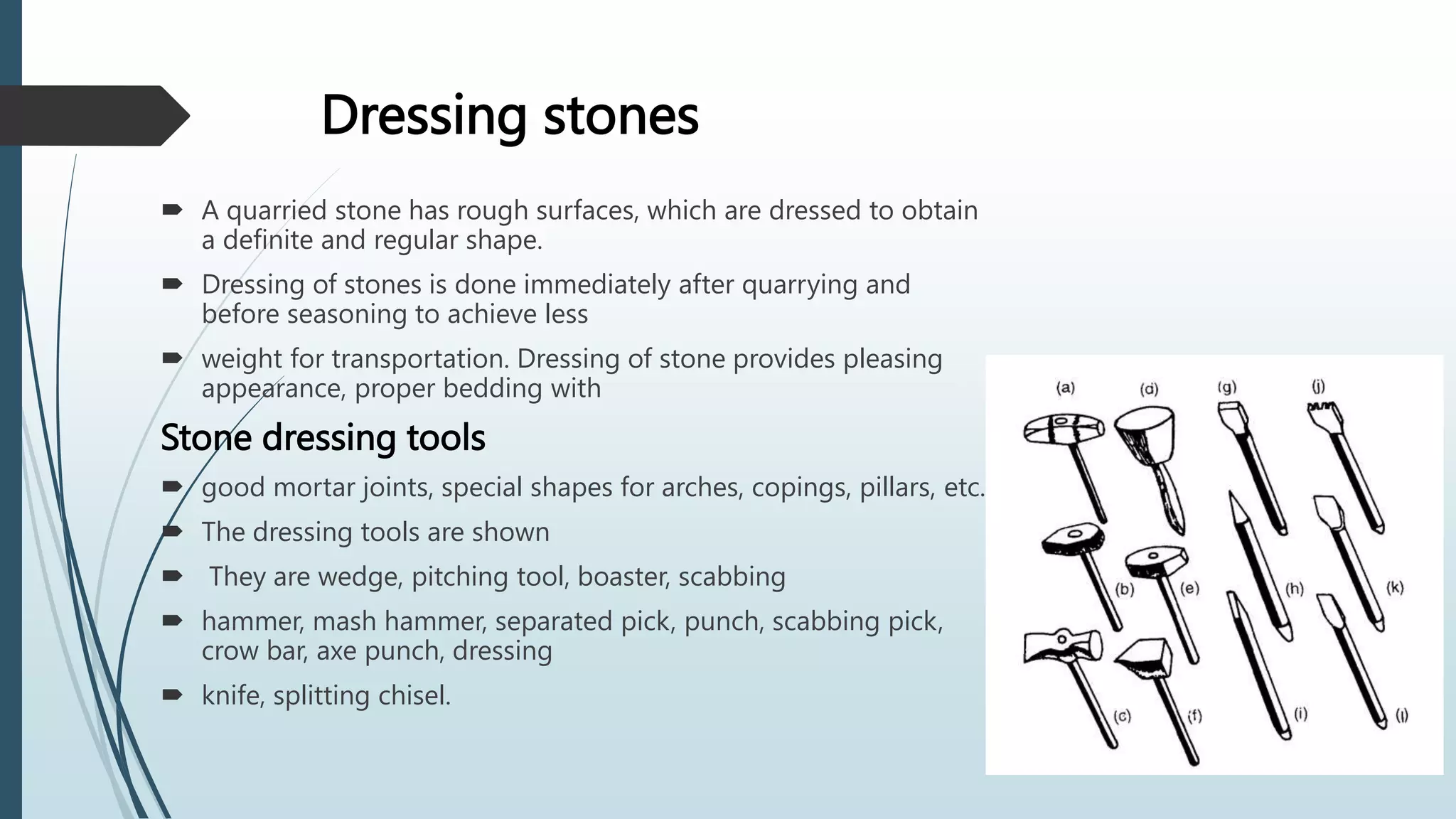

This document provides an overview of materials and methods used in construction, focusing on stone. It discusses the different types of stones used in building, their characteristics, quarrying, dressing, and testing. The key points covered include the classification of rocks, tools used in quarrying and dressing stones, common quarrying methods like wedging, blasting and heating, and desirable properties for building stones such as strength, weight, hardness, and resistance to weathering.