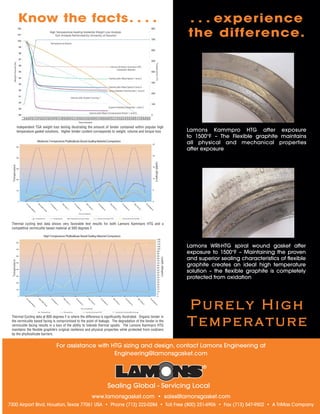

Lamons manufactures high-quality gasketing components for extreme industrial applications. They produce spiral wound gaskets, soft gaskets, ring joints, and other sealing products. Their HTG product family uses flexible graphite protected by mica/phyllosilicate barriers to provide sealing at extreme temperatures up to 1500°F while maintaining torque and tightness through thermal cycling. The flexible graphite maintains its properties while protected from oxidation, making the HTG gaskets the most stable sealing solution for demanding high-temperature industrial applications.