1. The document provides instructions for sampling gas and air at locations in a calcination workshop and analyzing the composition using a stack emission analyzer.

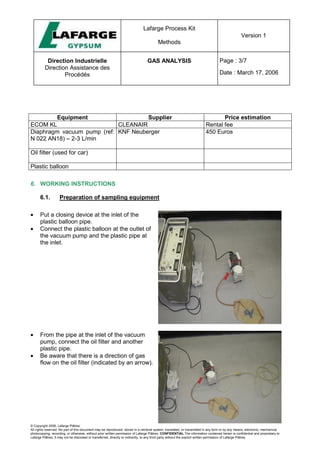

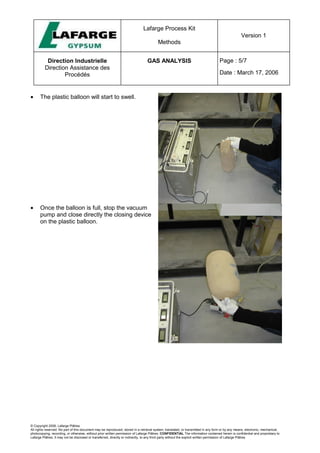

2. Gas sampling is done using a vacuum pump, plastic balloon, and stainless steel pipe to collect samples from the stack.

3. The sampled gas is then analyzed using a stack emission analyzer to measure levels of O2, CO2, CO, and NOx, which can be used to evaluate burner air excess or perform a thermal balance of the calcination workshop.