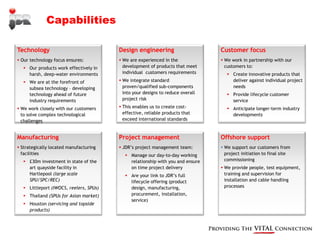

JDR is a leading provider of technology and services for the offshore energy industry, specializing in subsea production umbilicals, power cables, intervention workover control systems, and renewable energy cables. The company is committed to innovative solutions and customer partnerships, offering lifecycle support through engineering, installation, and maintenance services. With a global presence and a strong focus on safety, quality, and environmental compliance, JDR aims to meet the evolving needs of the oil, gas, and renewable energy markets.