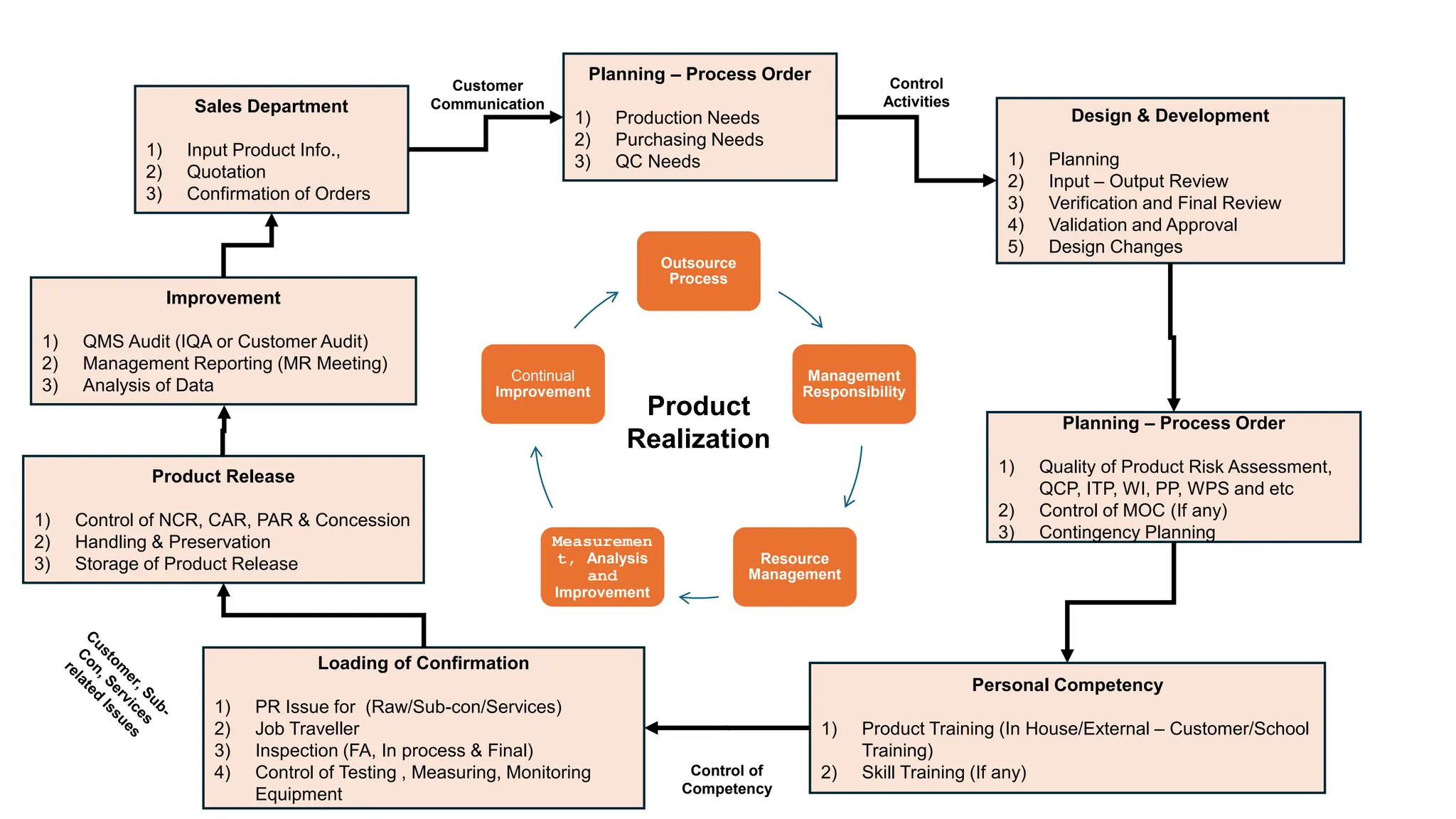

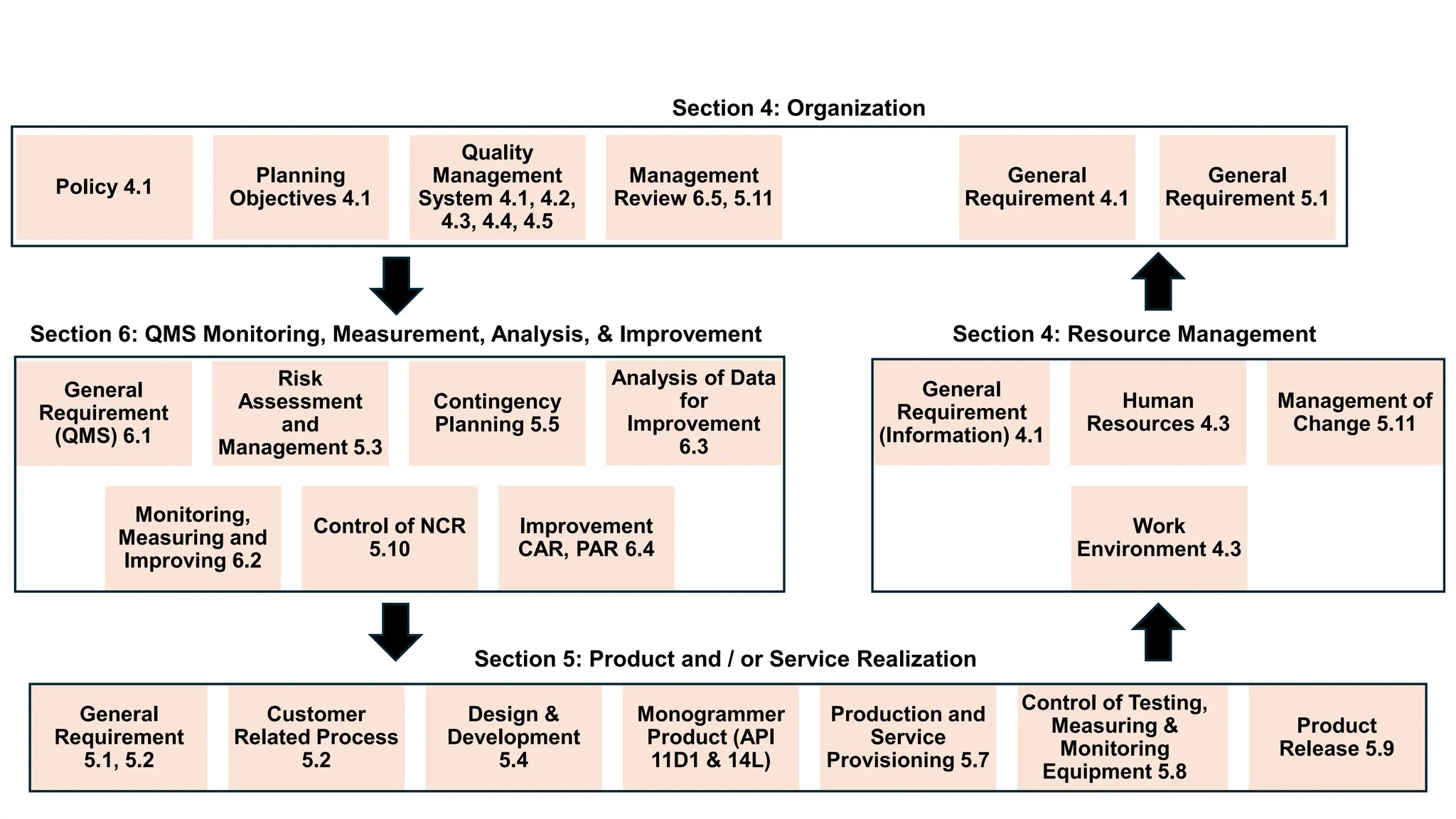

The document outlines a comprehensive process for managing product realization, including stages from order confirmation to design development and quality control. It emphasizes continual improvement through quality management system audits, competency training, and contingency planning. Key sections highlight objectives, risk assessment, resource management, and customer communication within the framework.