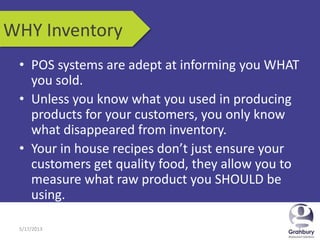

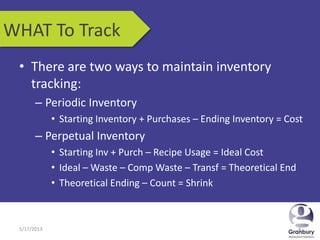

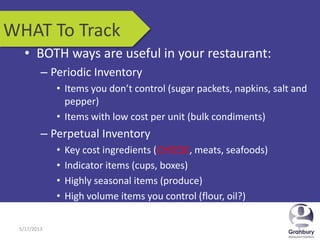

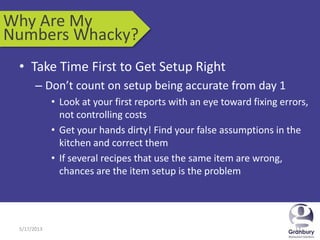

This document discusses best practices for inventory management in restaurants. It addresses who should be responsible for inventory tasks, what types of items should be tracked using periodic vs perpetual inventory methods, when key inventory activities like ordering, receiving, and counting should occur, and why accurate setup and tracking of inventory is important for controlling costs and increasing profits. Maintaining accurate inventory through daily discipline and periodic analysis of discrepancies can help recover half of inventory losses and improve gross profits.