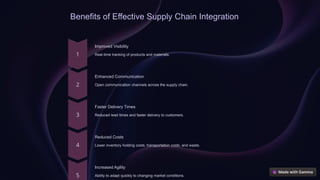

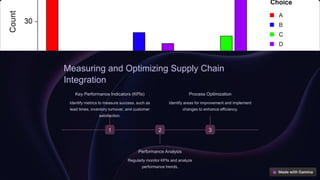

Supply chain integration involves connecting different parts of a company's supply chain to enhance efficiency, customer satisfaction, and profitability through collaboration and information sharing. Key components include demand planning, inventory management, production planning, and distribution, while challenges involve data silos and process complexity. Successful integration requires clear goals, trust-building, technology investment, and continuous improvement, along with measuring performance through key performance indicators.