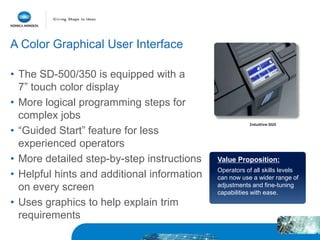

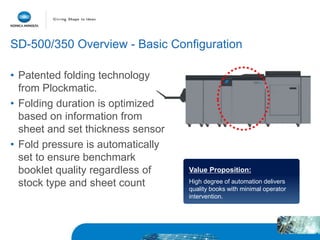

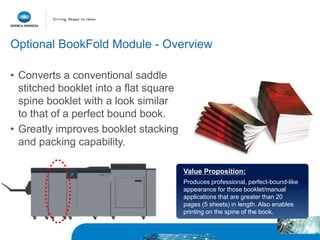

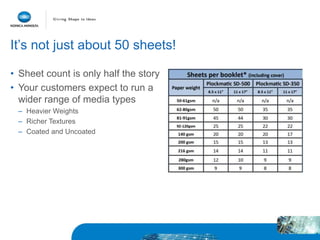

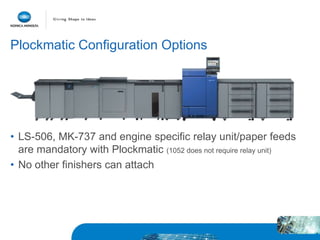

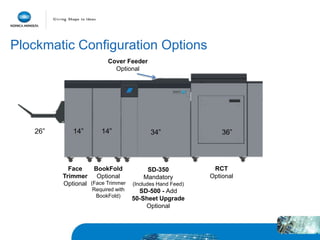

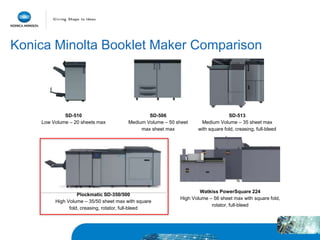

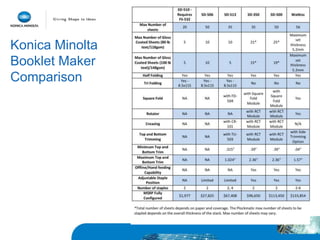

Plockmatic has introduced two new production booklet makers, the SD-500 and SD-350, designed for mid-range printing markets, with the SD-500 capable of producing 200-page booklets and the SD-350 offering cost-effective solutions for 140-page booklets. Both models feature advanced automation, user-friendly interfaces, and the ability to upgrade, making them versatile for various booklet applications, while supporting high-quality output with minimal operator intervention. Additional options, such as the bookfold and trimming modules, enhance both efficiency and the professional appearance of finished booklets.