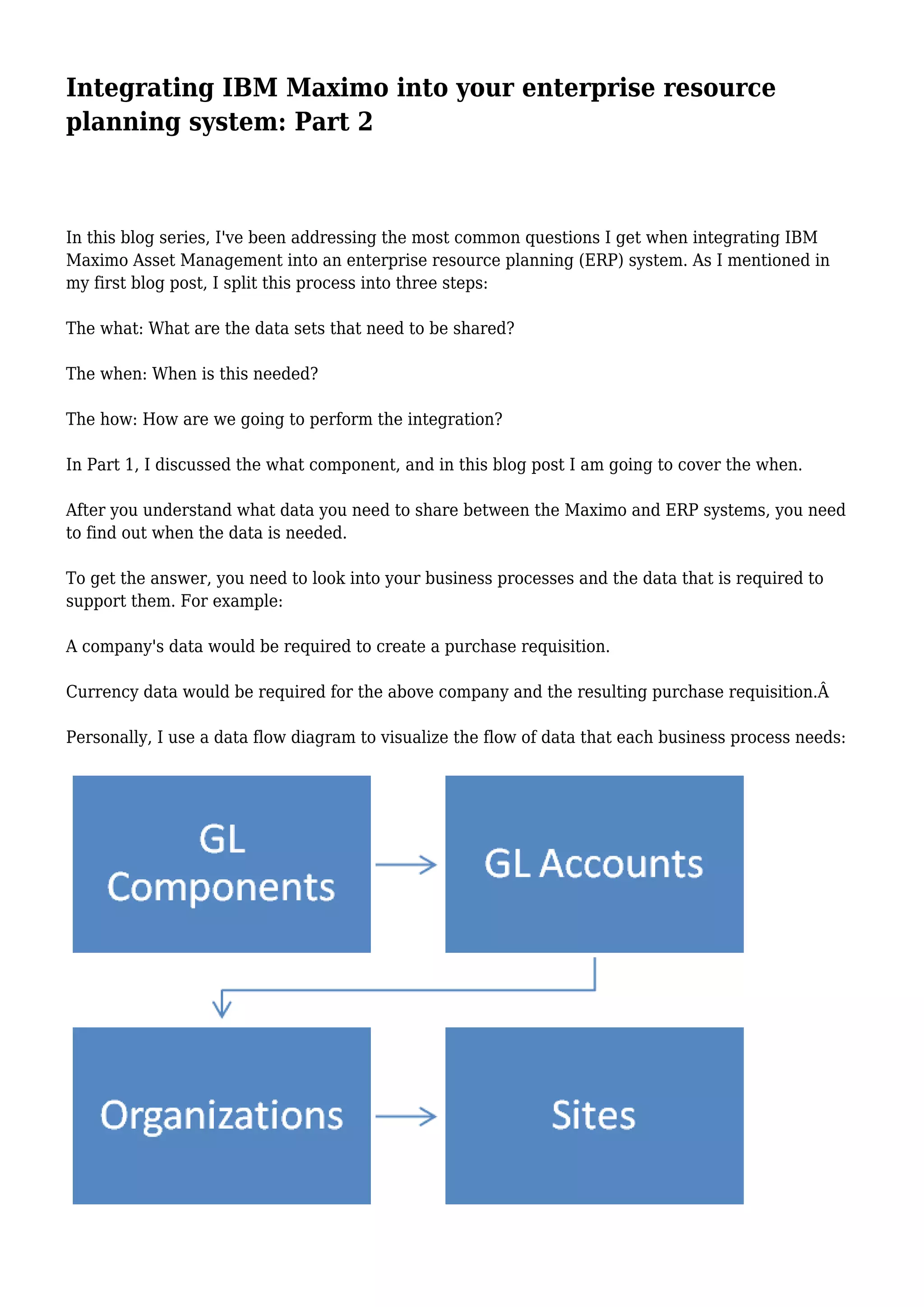

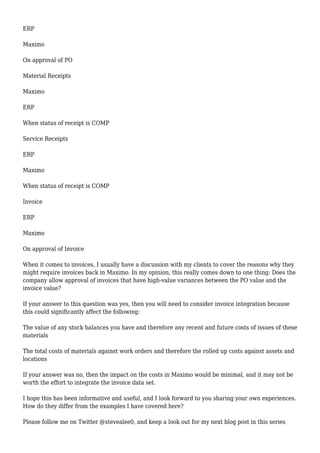

This blog post is the second in a series discussing the integration of IBM Maximo asset management with ERP systems, focusing on when data is needed for business processes. It details the importance of understanding data flow and timing, differentiating between real-time and batch integration based on specific processes within an organization. Additionally, it raises the question of integrating invoices based on variance in values, which can significantly impact cost management in Maximo.