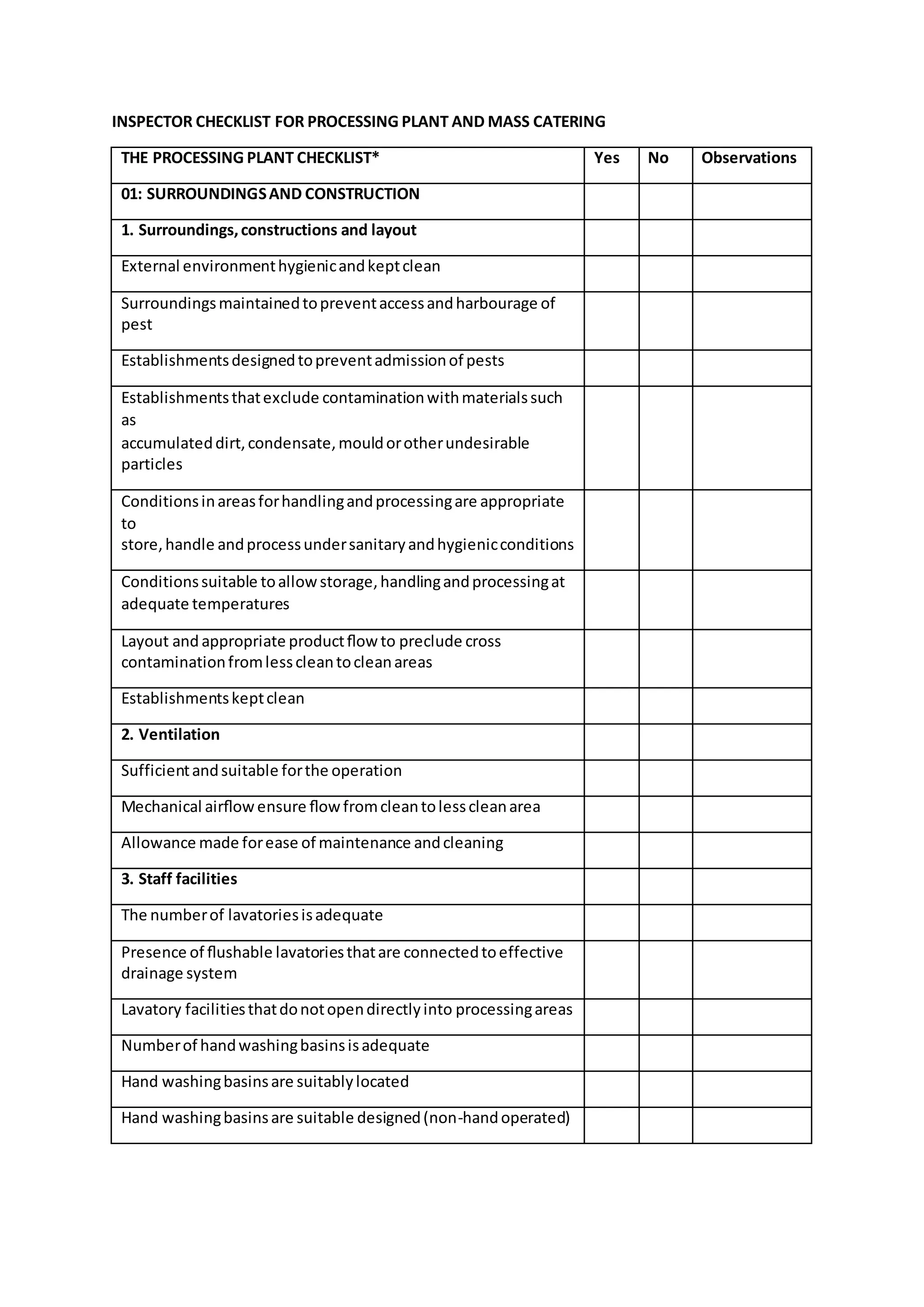

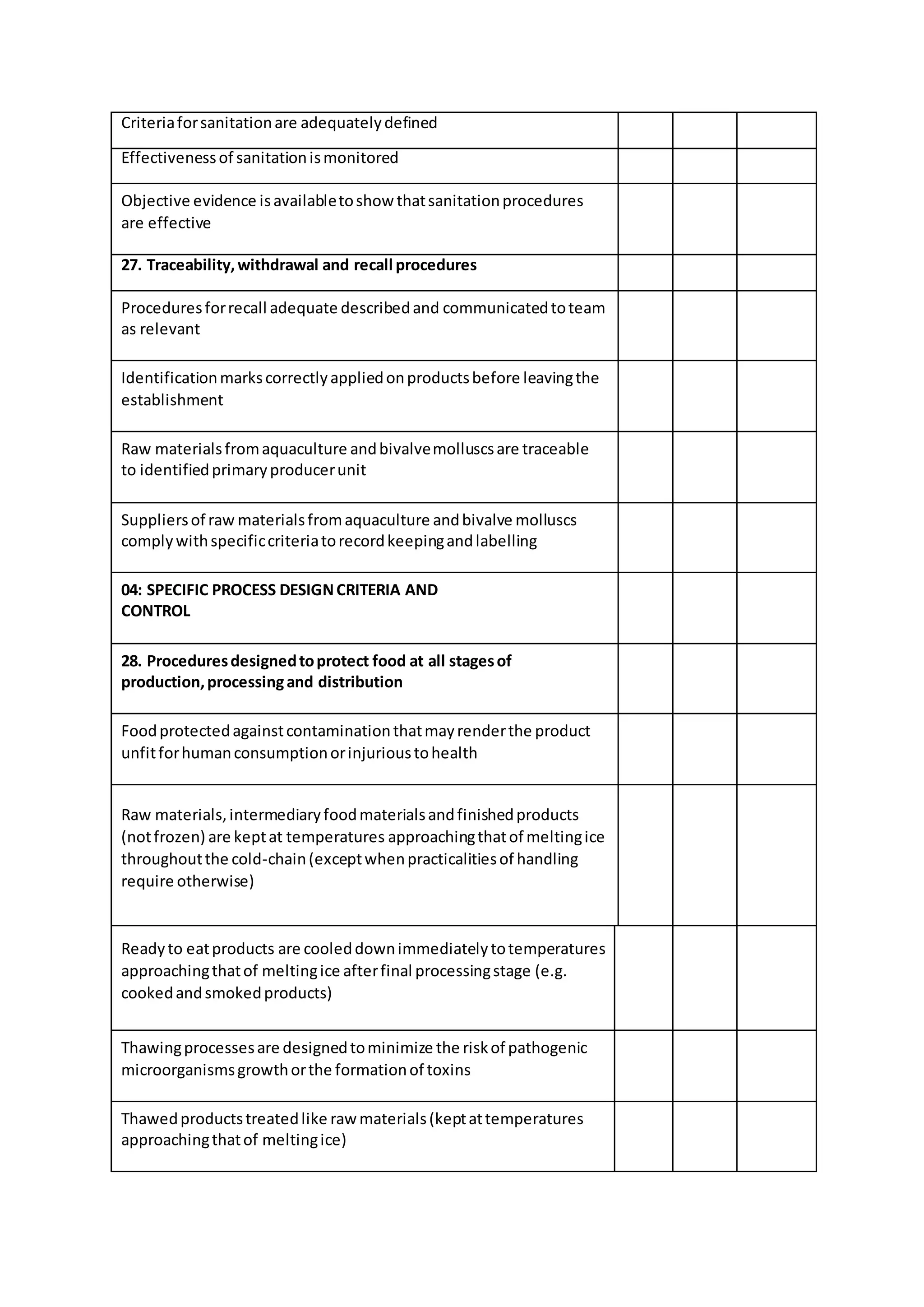

This document provides an inspector checklist for processing plants and mass catering facilities. It includes over 100 criteria across topics like surroundings and construction, staff facilities, lighting, drainage systems, storage, construction requirements in food handling areas, implementation of prerequisite programs, and specific process design criteria and controls. The checklist ensures facilities meet hygienic standards to prevent contamination and allow for safe food production, processing, and distribution.