First Aid Injury at Work - Dressed Finger Hurt on Hose

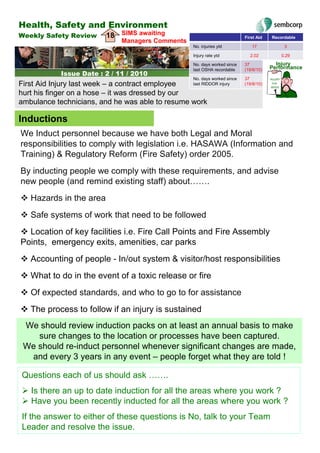

- 1. First Aid Injury last week – a contract employee hurt his finger on a hose – it was dressed by our ambulance technicians, and he was able to resume work Health, Safety and Environment Weekly Safety Review Issue Date : 2 / 11 / 2010 SIMS awaiting Managers Comments First Aid Recordable No. injuries ytd 17 3 Injury rate ytd 2.02 0.29 No. days worked since last OSHA recordable 37 (19/8/10)10) No. days worked since last RIDDOR injury 37 (19/8/10)10 18 INJURY THS WEEK Injury Performance 1 Questions each of us should ask ……. Is there an up to date induction for all the areas where you work ? Have you been recently inducted for all the areas where you work ? If the answer to either of these questions is No, talk to your Team Leader and resolve the issue. Inductions We Induct personnel because we have both Legal and Moral responsibilities to comply with legislation i.e. HASAWA (Information and Training) & Regulatory Reform (Fire Safety) order 2005. By inducting people we comply with these requirements, and advise new people (and remind existing staff) about……. Hazards in the area Safe systems of work that need to be followed Location of key facilities i.e. Fire Call Points and Fire Assembly Points, emergency exits, amenities, car parks Accounting of people - In/out system & visitor/host responsibilities What to do in the event of a toxic release or fire Of expected standards, and who to go to for assistance The process to follow if an injury is sustained We should review induction packs on at least an annual basis to make sure changes to the location or processes have been captured. We should re-induct personnel whenever significant changes are made, and every 3 years in any event – people forget what they are told !