Highway failures not only cause traffic delays but also pose serious safety risks. Thorough testing helps identify weak zones, ensures compliance with design standards, and ultimately saves time and cost on future maintenance.

In India, government bodies like MoRTH, NHAI, and state PWDs have laid down detailed specifications for testing roads condition before declaring them open to traffic.

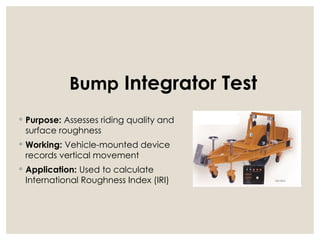

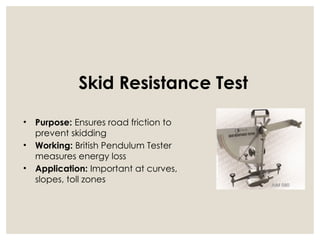

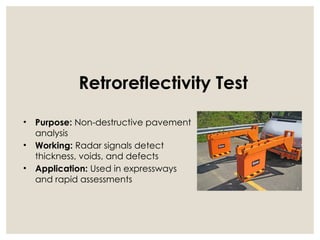

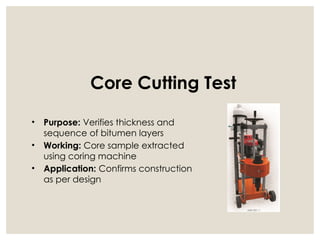

Here are some important tests on newly constructed roads and Highways