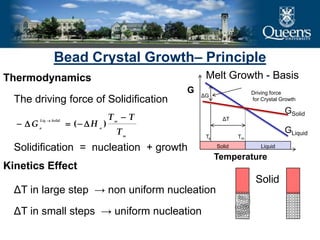

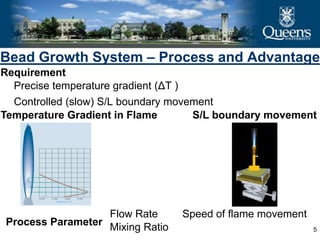

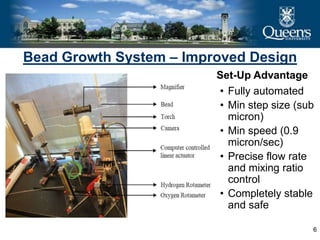

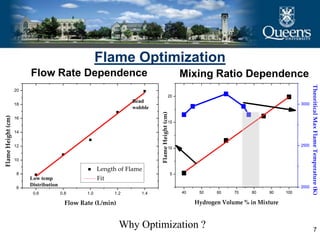

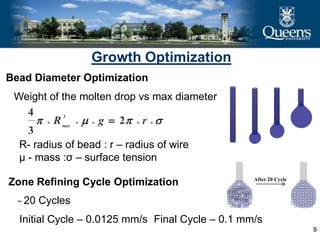

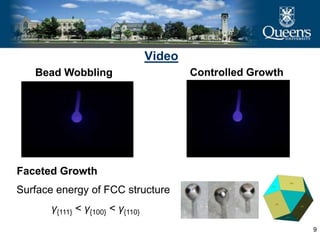

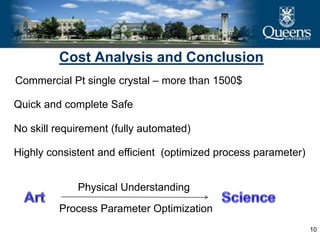

This document summarizes work done to develop an improved automated bead growth facility for growing platinum nanocrystal surfaces. It describes the motivation to study heterogeneous electrocatalyst surfaces at the nanoscale. An automated bead growth system was developed that allows for precise temperature gradients and crystal growth rates through optimized flame conditions and growth parameters. This allows for controlled faceted crystal growth and characterization of platinum nanosurfaces. The new system provides a low-cost alternative to commercial platinum single crystals for fundamental surface science studies.