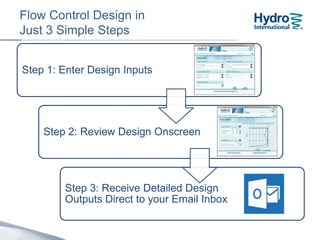

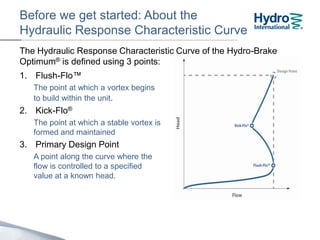

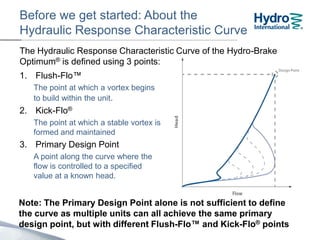

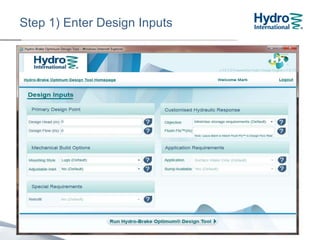

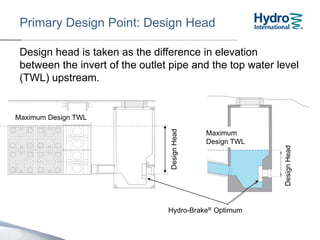

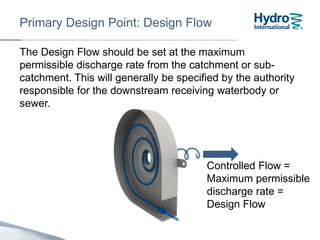

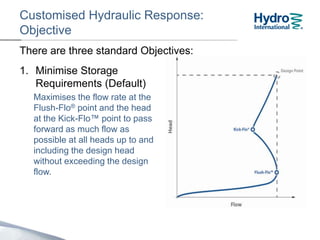

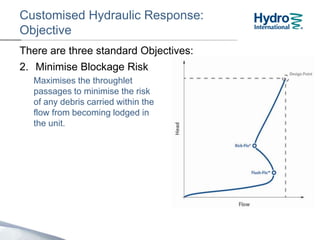

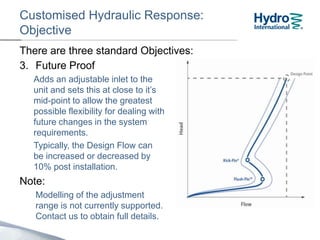

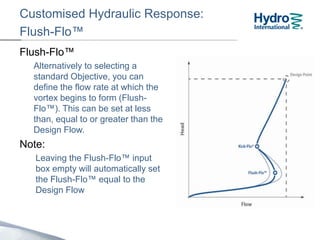

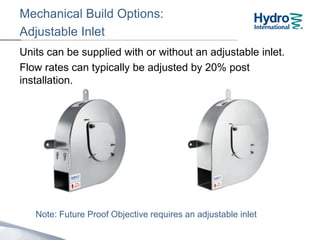

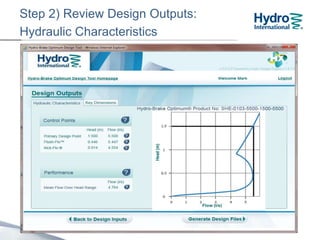

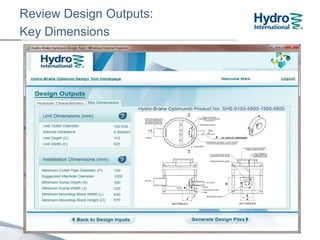

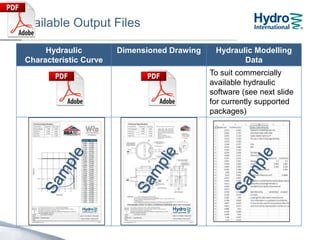

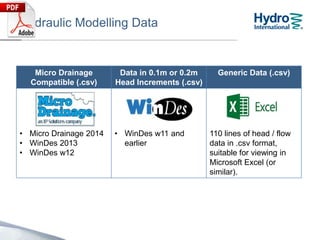

This document provides a step-by-step guide to using a design tool for Hydro-Brake Optimum flow control devices. The tool allows users to enter design inputs like head, flow, and mounting options. It then provides design outputs, including hydraulic characteristic curves, dimensions, and downloadable design files. Key inputs include design head, flow, and objectives to minimize storage, blockage risk, or allow for future changes. Outputs include reviewed dimensions and files for hydraulic modeling software.