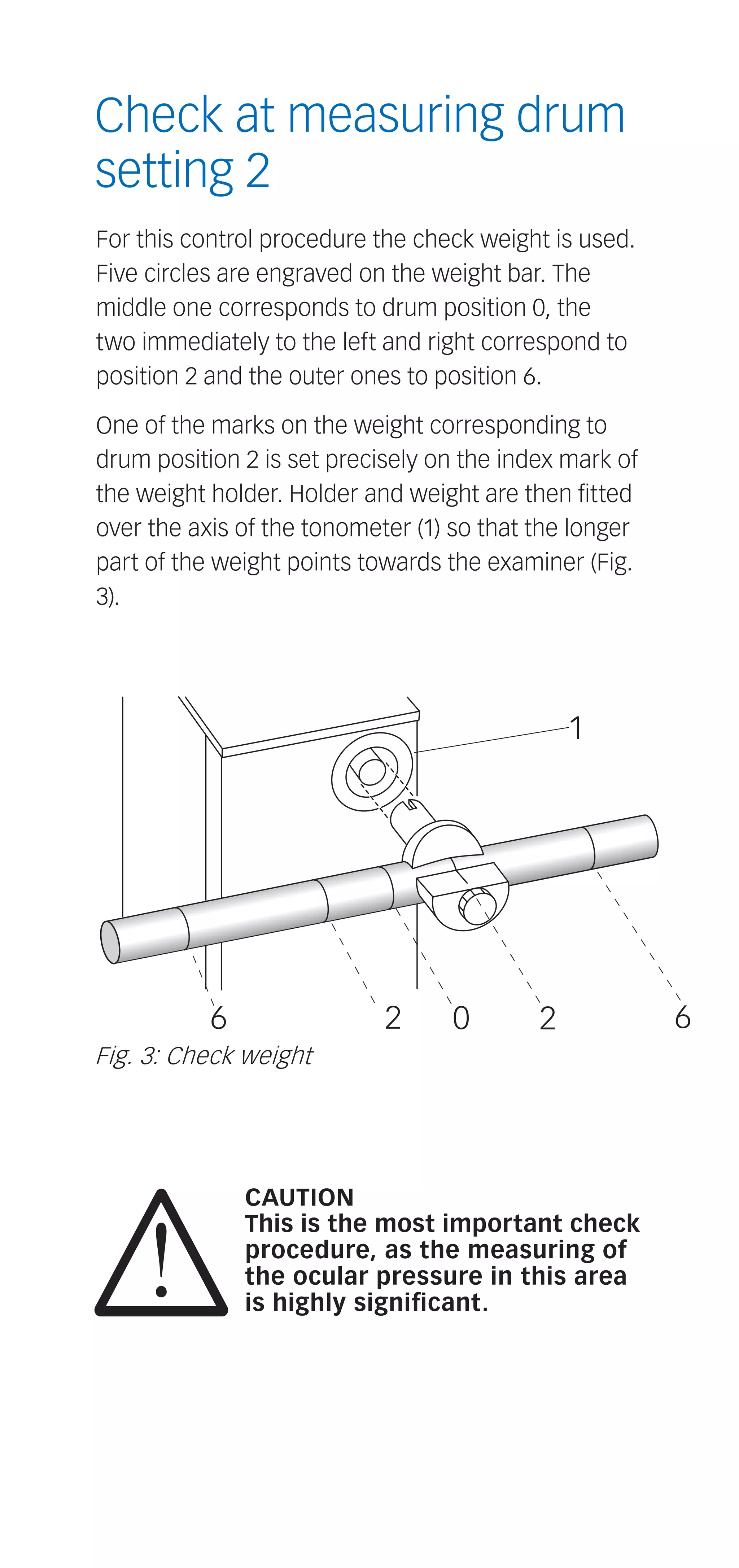

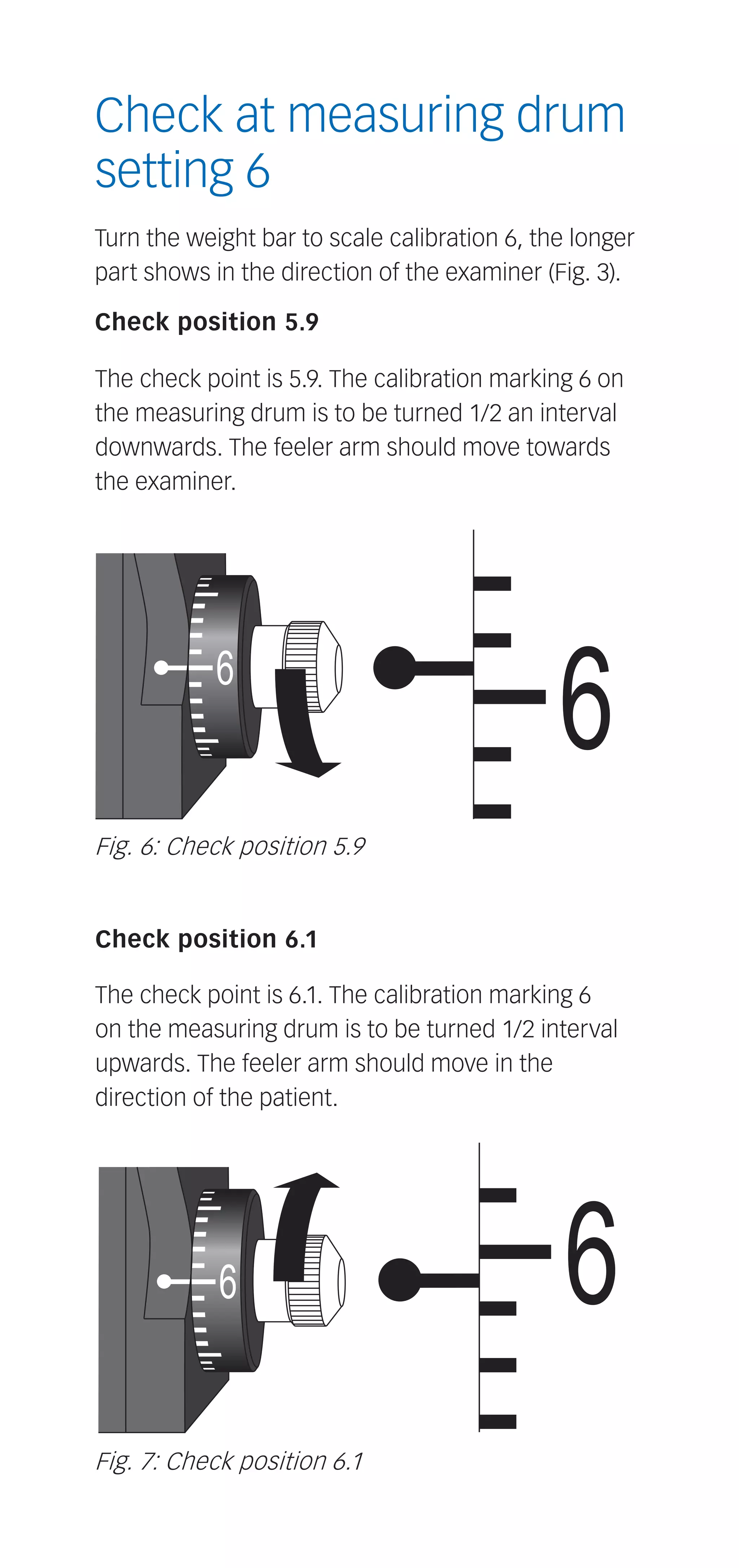

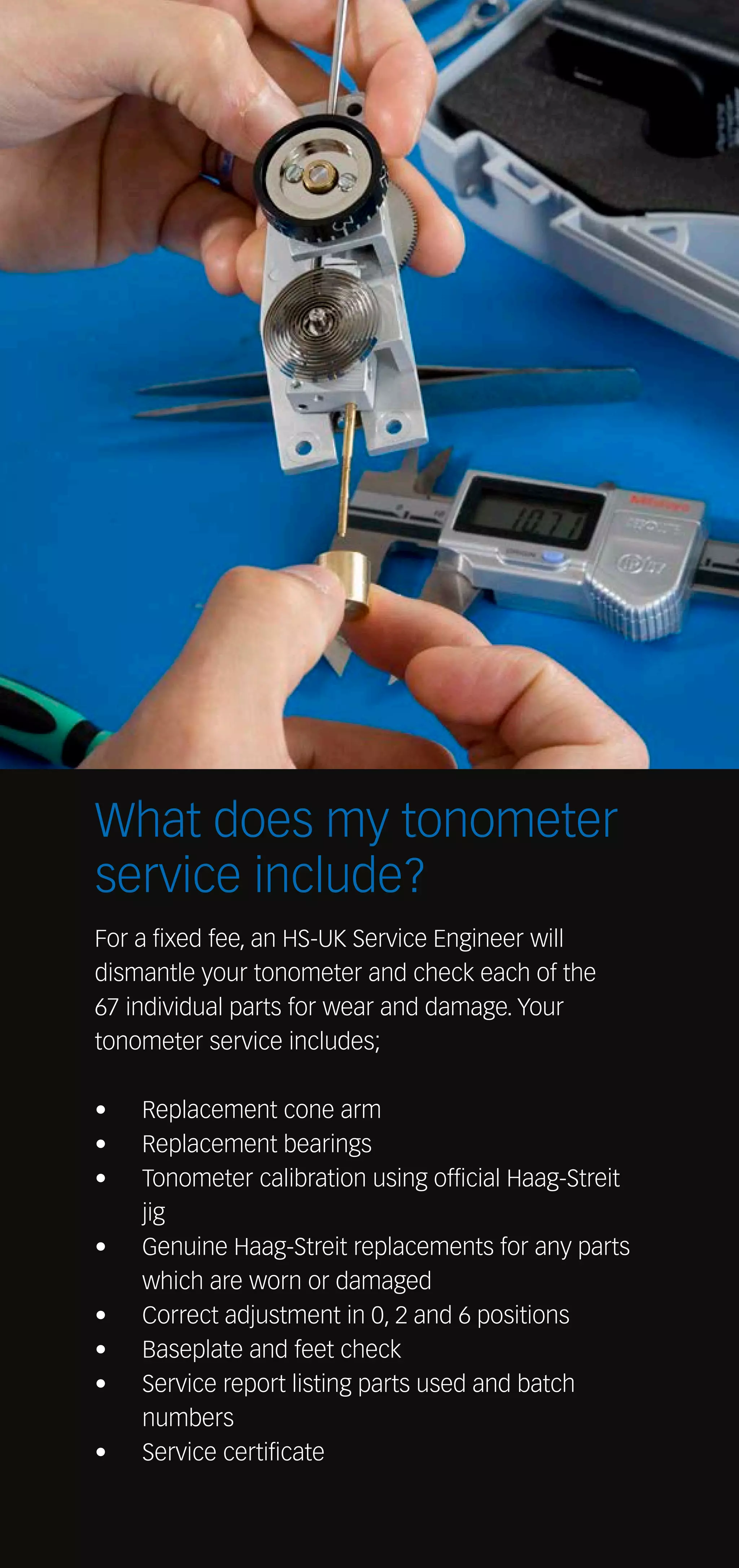

The document provides guidance on checking the calibration of tonometers to ensure accurate measurements and patient safety, highlighting the need for monthly checks as recommended by Haag-Streit guidelines. It details specific checking procedures for different tonometer models, including the necessary adjustments and positions to assess. Additionally, it explains the repair and servicing process available through HS-UK, emphasizing that they use genuine Haag-Streit parts and comply with applicable standards.