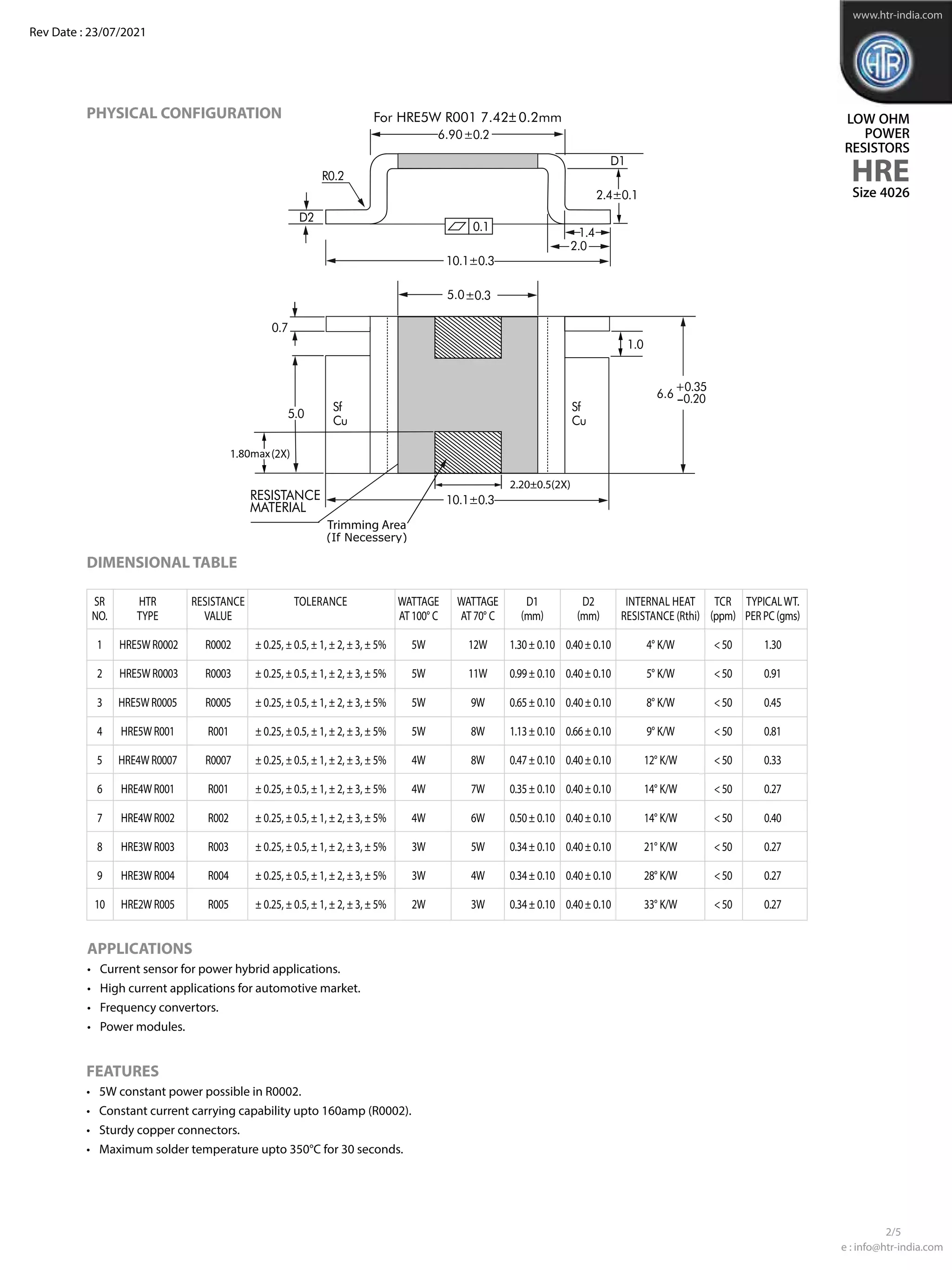

This document provides information about low ohm power resistors made by HTR India. It includes specifications for resistance values and tolerances, power ratings at different temperatures, dimensions, applications like current sensors and power modules, features like maximum current capacity and solder temperature resistance, recommended layout and solder profile, electrical and environmental test results, derating curves, ordering information examples, and packaging in bulk boxes or tape and reel. The resistors are open frame welded designs for applications requiring high current capacity.

![RECOMMENDED PCB - LAYOUT

LOW OHM

POWER

RESISTORS

HRE

www.htr-india.com

Rev Date : 23/07/2021

Size 4026

RECOMMENDED SOLDER PROFILE

Reflow, IR - Soldering

Temperature (°C) 260 255 217

Time (Sec) Peak 40 90

e : info@htr-india.com

3/5

ELECTRICAL AND ENVIRONMENTAL CHARACTERISTICS

PARAMETER / PERFORMANCE TEST & TEST METHOD PERFORMANCE REQUIREMENTS

Power Rating For FeCrAl - Full power dissipation at 70° C and linearly derated to

zero at +170° C.

For Manganin (< 0.5% Improved Stability) -

Full power dissipation at 100° C & linearly derated to zero at +140° C.

For Manganin (< 1% Stability) - Full power dissipation at 130° C and

linearly derated to zero at +170° C.

Inductance < 3nH

Temperature Range - 65° C to +170° C (Suitably derated as per derating curve provided)

Voltage Rating / LimitingVoltage / Max.WorkingVoltage

(Subject to max.TerminalTemperature of 130° C)

LowTemperature Storage and Operation [-65° C for 250 h] ∆R ± 0.1% - Average

Temperature Coefficient of Resistance <50 ppm / K (Depending on Resistance Value)

(AmbientTemperature Range 20° C - 60° C)

Temperature Cycling -2000 cycles (-55° C to 150° C) ∆R ± 0.5% - Average

LifeTest / Operational Life - 2000 h rated power with ∆R ± 1% - Average

Temperature limitation onTerminal kept at 130° C

Moisture Resistance [MIL-STD-202 method106] ∆R ± 0.1% - Average

Mechanical Shock [100 g. 6 ms half sine] ∆R ± 0.2% -Typical

Vibration, High Frequency [20 g. 10-2000 Hz] ∆R ± 0.2% -Typical

Bias Humidity [+85° C, 85% RH, 1000h] ∆R ± 0.5% -Typical

Resistance to Soldering Heat 260°C for 10 sec / 8h steam aging

HighTemperature Exposure – 2000h / 170°C ΔR ± 1% - Average (In covered condition)

P x R](https://image.slidesharecdn.com/hre-210805095602/75/Hre-3-2048.jpg)

![LOW OHM

POWER

RESISTORS

HRE

e : info@htr-india.com

www.htr-india.com

Rev Date : 23/07/2021

Size 4026

4/5

TYPICAL POWER DERATING CURVE FOR

RESISTOR WHEn full power is at 100oC & 130oC

TYPICAL POWER DERATING CURVE FOR

RESISTOR WHEn full power is at 70oC

In case the Design Engineer requires a specific graph of a particular component it can be supplied on request.

TYPICAL TEMPERATURE DEPENDANCE electrical resistance

MAXIMUM PULSE ENERGY WITH RESPECT TO PULSE POWER FOR PERMANANT OPERATION

In this graph the max. & min. curve are shown as and for all resistance values, the area between the max. & min. curve is applicable.

In case the Design Engineer requires a specific graph of a particular component it can be supplied on request.

1

0.75

0,5

0.25

0

0 20 40 60 80 100 120 140 160 180

1.25

Terminal Temperature [°C]

P(W)/P

Stability <1.0% (in covered condition)

Stability <0.5%

Nom

Stability <1.0% (in covered condition)

1

0.75

0,5

0.25

0

0 20 40 60 80

70 100 120 140 160 180

1.25

Terminal Temperature [°C]

P(W)/PNom

0.8

0.6

0.4

-0.2

0

-0.2

-0.4

-0.6

-0.8

1

-40 -20 0 20 40 60 80 100 120 140

Temperature [°C]

dR/R20 [%]

Typical temperature dependence of a resistor made with Mangnin

Limiting Curve

-1

1.0

0.5

0.0

-0.5

-1.0

-40 -20 0 20 40 60 80 100 120 140 160

Temperature [°C]

dR/R20 [%]

Typical temperature dependence of a resistor made with FeCrAl

Limiting Curve

10000

1000

100

10

1

1

10000 1000

10 100

0.0001

0.001

0.01

0.1

1

10

100

0.1

0.1

0.01

0.01

Pulse width [sec]

Pulse

energy

[J]

Power

[W]](https://image.slidesharecdn.com/hre-210805095602/75/Hre-4-2048.jpg)