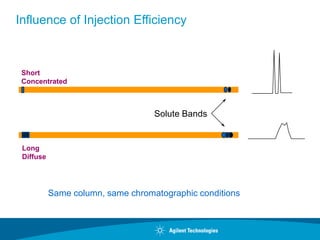

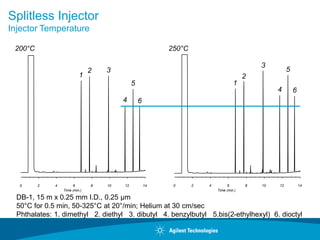

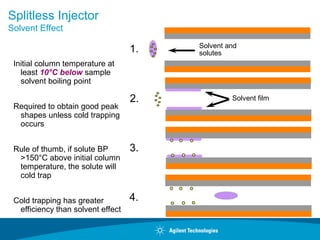

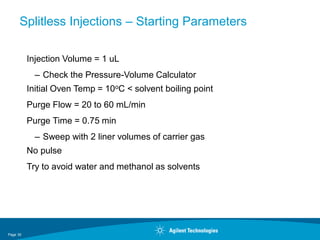

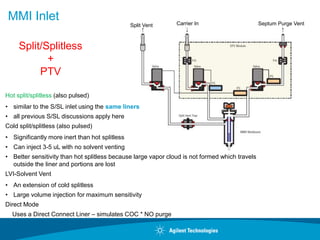

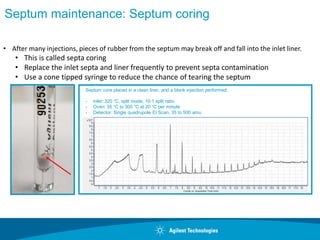

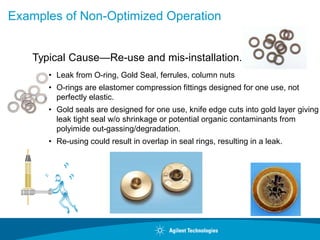

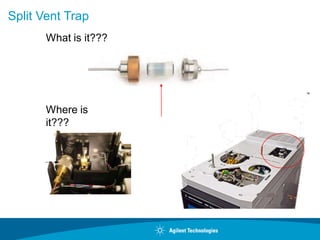

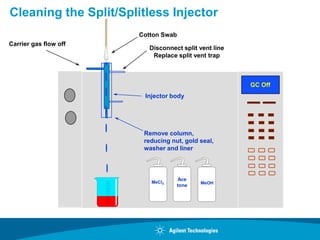

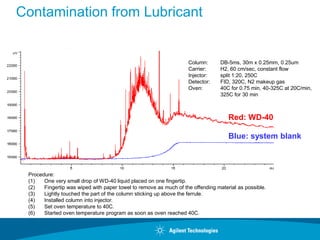

The document provides an extensive guide on gas chromatography (GC) inlet types and their maintenance, focusing on split, splitless, and pulsed splitless injection modes for optimal sample introduction. It details the influence of injection efficiency on outcomes, the role of liner selection, sample concentration, and system setup to enhance sensitivity and minimize discrimination. Additionally, it covers troubleshooting techniques for common issues, such as liner contamination and septum leaks, to ensure reliable chromatographic results.