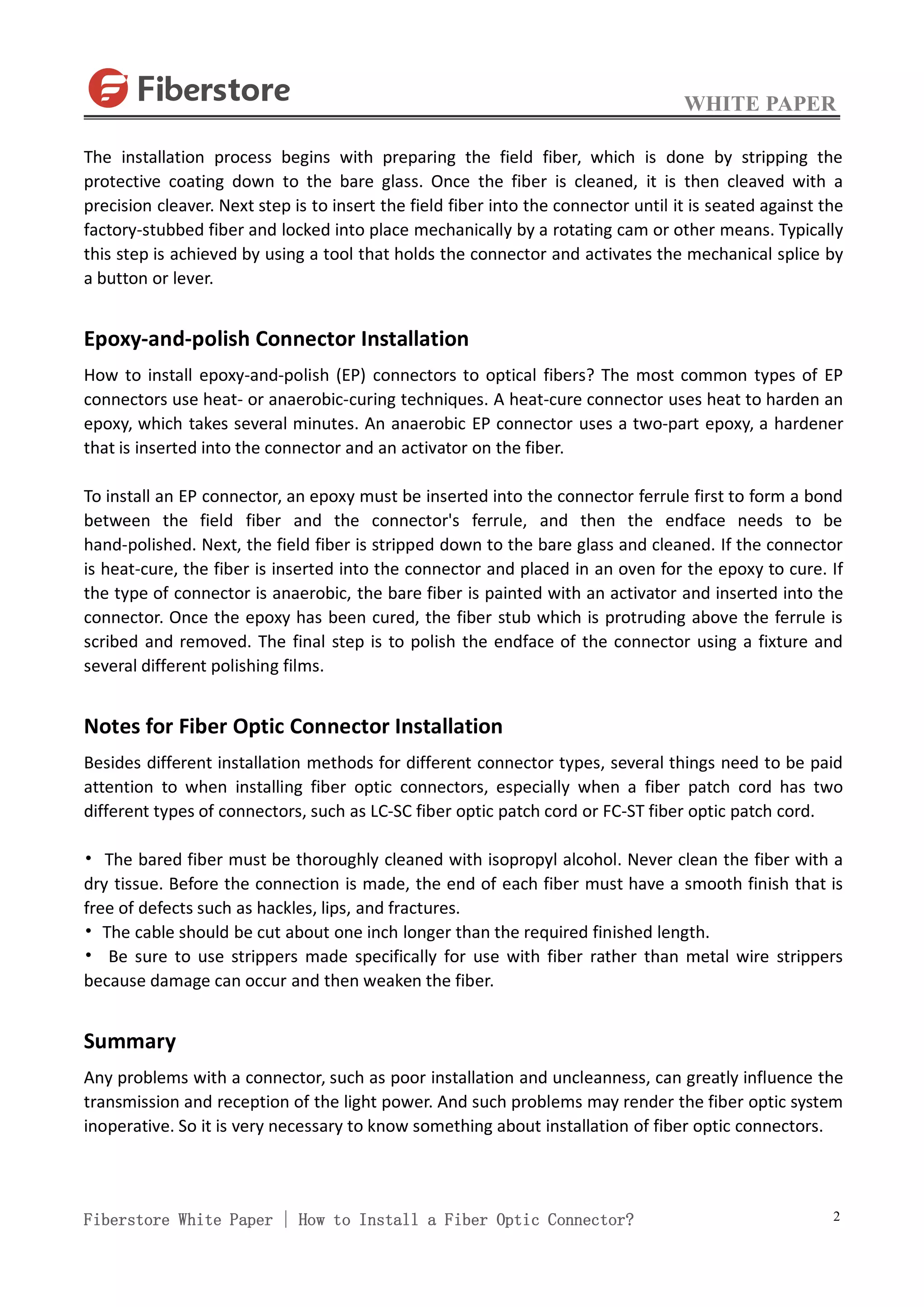

The document provides a guide on how to install two types of fiber optic connectors: no-epoxy/no-polish and epoxy-and-polish connectors. It details the step-by-step installation procedures for each type, emphasizing the importance of proper cleaning and handling of fiber to ensure optimal connection performance. Additionally, it mentions that issues with connector installation can significantly affect light transmission, potentially rendering the fiber optic system inoperative.