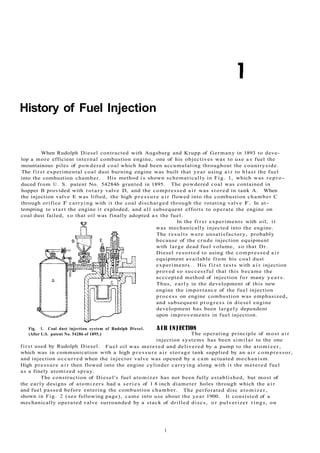

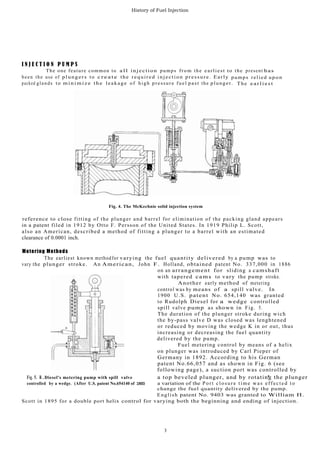

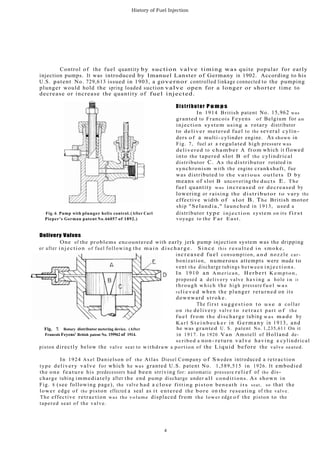

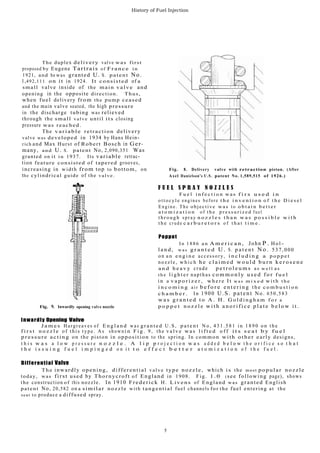

Rudolph Diesel originally experimented with injecting powdered coal into his engine using compressed air, which failed. He then switched to injecting oil using compressed air, which was successful. Early fuel injection systems used compressed air to atomize the fuel. Over time, mechanical injection pumps were developed to pressurize the fuel. Early nozzles had multiple holes but single-hole swirl nozzles became popular. Delivery valves were improved to prevent dripping after injection. Common components of modern injection systems, like distributor pumps and inwardly opening nozzles, were introduced in the early 20th century. Developments in injection pumps, delivery valves, and nozzles improved atomization and engine performance.