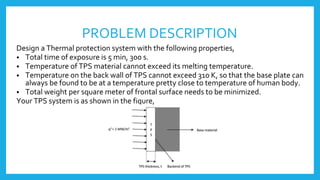

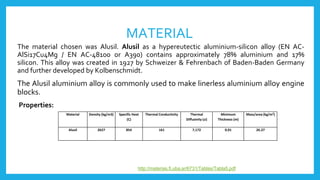

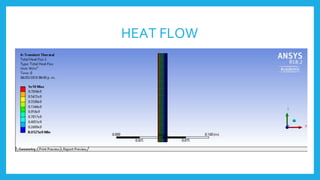

The document analyzes heat transfer in aerospace applications. The objective is to analyze heat transfer behavior to obtain performance of thermal protection systems by researching materials with different thermal properties. It discusses how heat is transferred between objects at different temperatures according to the zeroth law of thermodynamics and heat capacity. The problem describes designing a thermal protection system that must withstand 5 minutes of exposure at temperatures below the material's melting point and 310K on the back wall. Alusil alloy is chosen as the material due to its properties including density, specific heat, thermal conductivity, and diffusivity. Graphs show temperature over time and heat flow for the system.