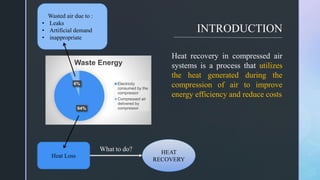

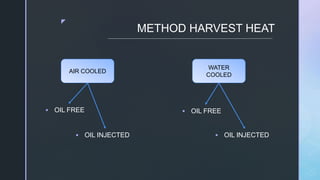

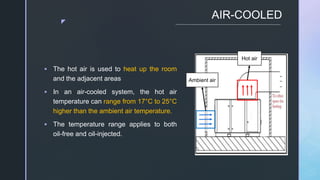

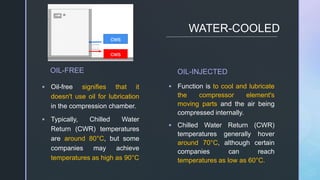

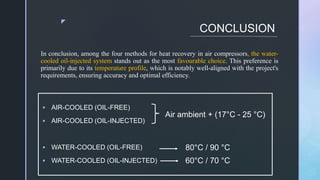

The document discusses heat recovery in compressed air systems, highlighting that significant energy is wasted during operation due to leaks and improper heat recovery. It compares air-cooled and water-cooled systems, noting that water-cooled oil-injected systems are the most efficient due to their favorable temperature profiles. Ultimately, optimizing heat recovery can improve energy efficiency and reduce operational costs.