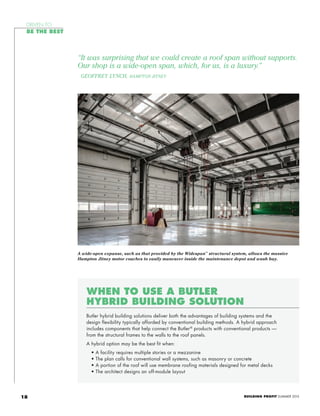

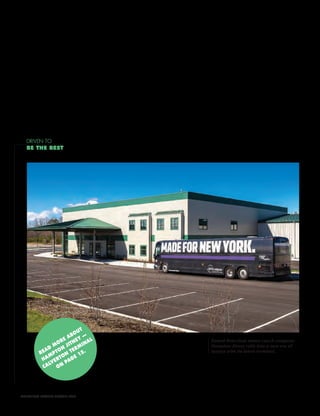

Hampton Jitney, an iconic luxury shuttle service in New York's Hamptons, has expanded with a new terminal and maintenance facility in Calverton, designed for optimal functionality and aesthetics. The facility, featuring a widespan structural system to allow for easy maneuverability and various roofing solutions, will serve over 1,000 customers per day during peak season. This development marks a significant milestone in the company’s growth, reflecting its commitment to offering a first-class passenger experience.