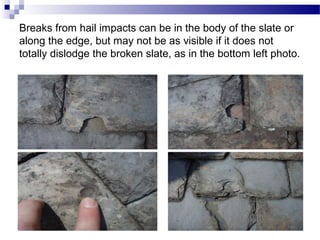

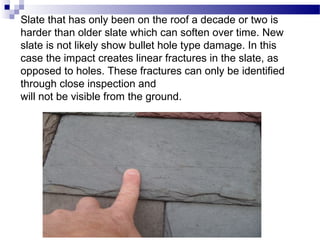

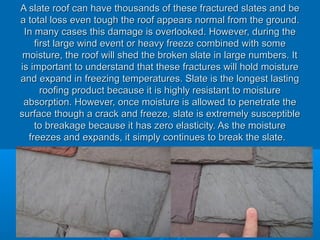

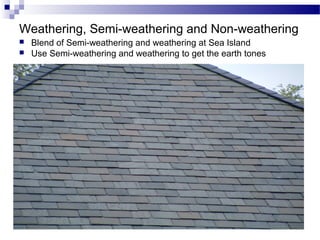

This document discusses insurance claims for hail damage on slate roofs. It notes that hail damage may not always be visible in the form of bullet holes and can appear as edge breaks or cracks. Close inspection is needed to identify fresh fractures underneath aging and dirt. While new slate may show fractures rather than holes, older slate can have thousands of fractured slates leading to total loss. Fractures allow water to penetrate and cause further breakage when freezing. The document provides guidance on assessing damage levels and determining whether repair or full replacement is needed.