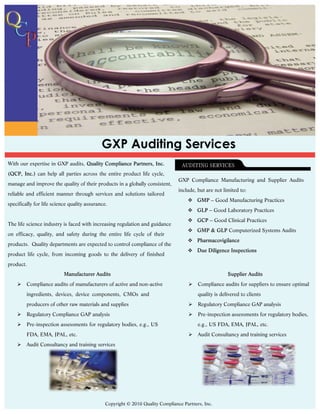

GXP Auditing Services provides auditing services to help life science companies ensure compliance and quality across the product lifecycle. This includes audits of manufacturing facilities, suppliers, clinical trials, laboratories, and pharmacovigilance activities to evaluate adherence to good practices. Life science companies face increasing regulation and financial pressures, so these audits help manage risk and identify areas for improvement. GXP Auditing Services has experienced auditors who can independently assess clinical programs to provide due diligence for companies considering in-licensing products.