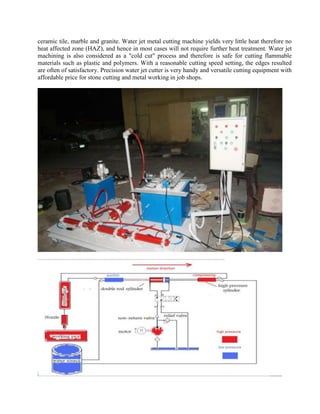

The document is a final year project presentation for a water jet cutting machine developed by three students - Ammar Ahmed Abdellah, Mohamed Ibrahim El-abd, and TarekAbd El-latifFouad - at the Arab Academy for Science, Technology and Maritime Transport, under the supervision of Dr. Mohamed abd el-mohsen. It begins by acknowledging the support received from their department head, project supervisor, and a teacher's assistant. The introduction provides a high-level overview of what a water jet cutting machine system is, explaining that it uses high pressure water jets, with or without abrasives, to cut a variety of materials like metals, stone, plastics