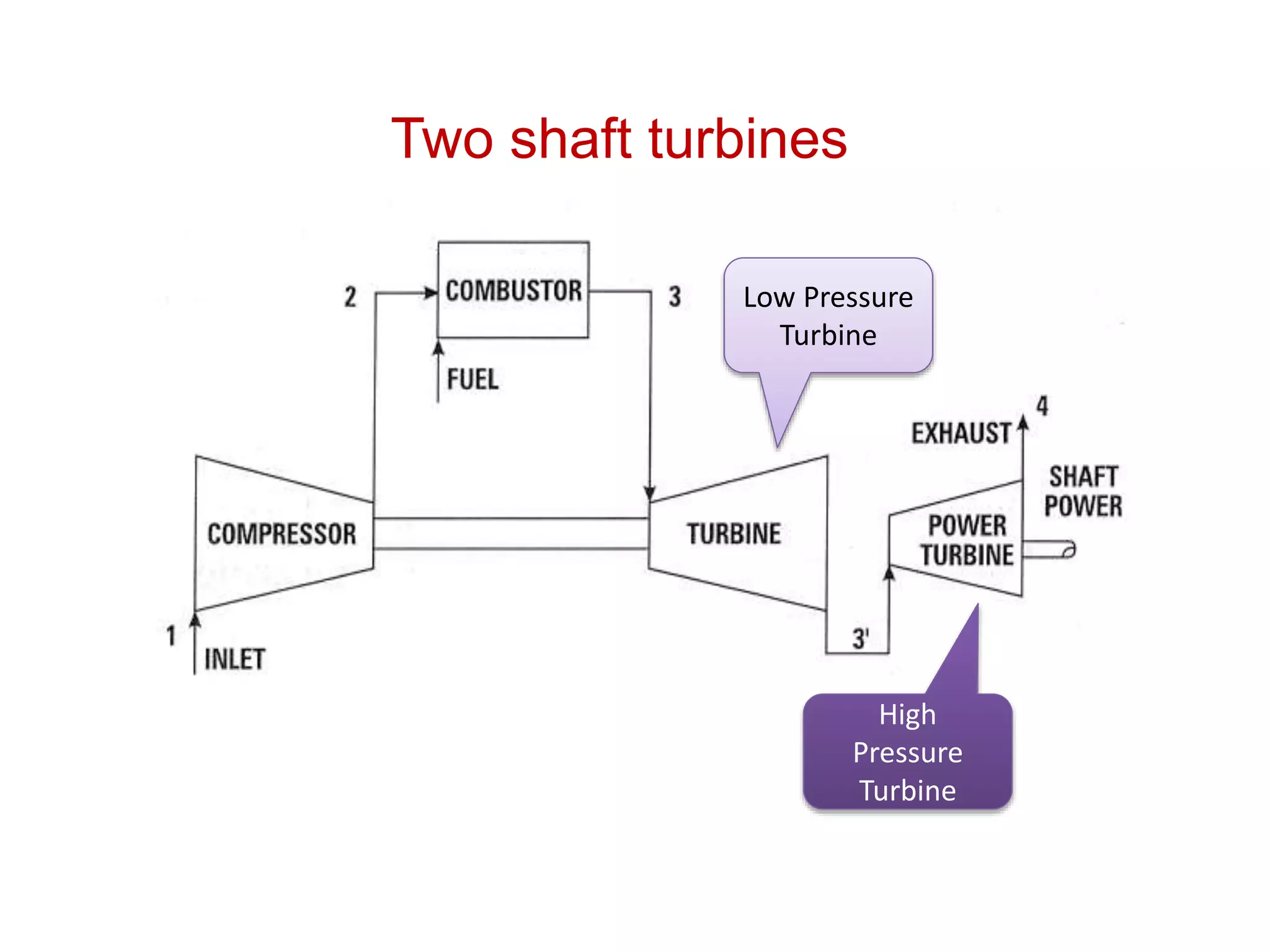

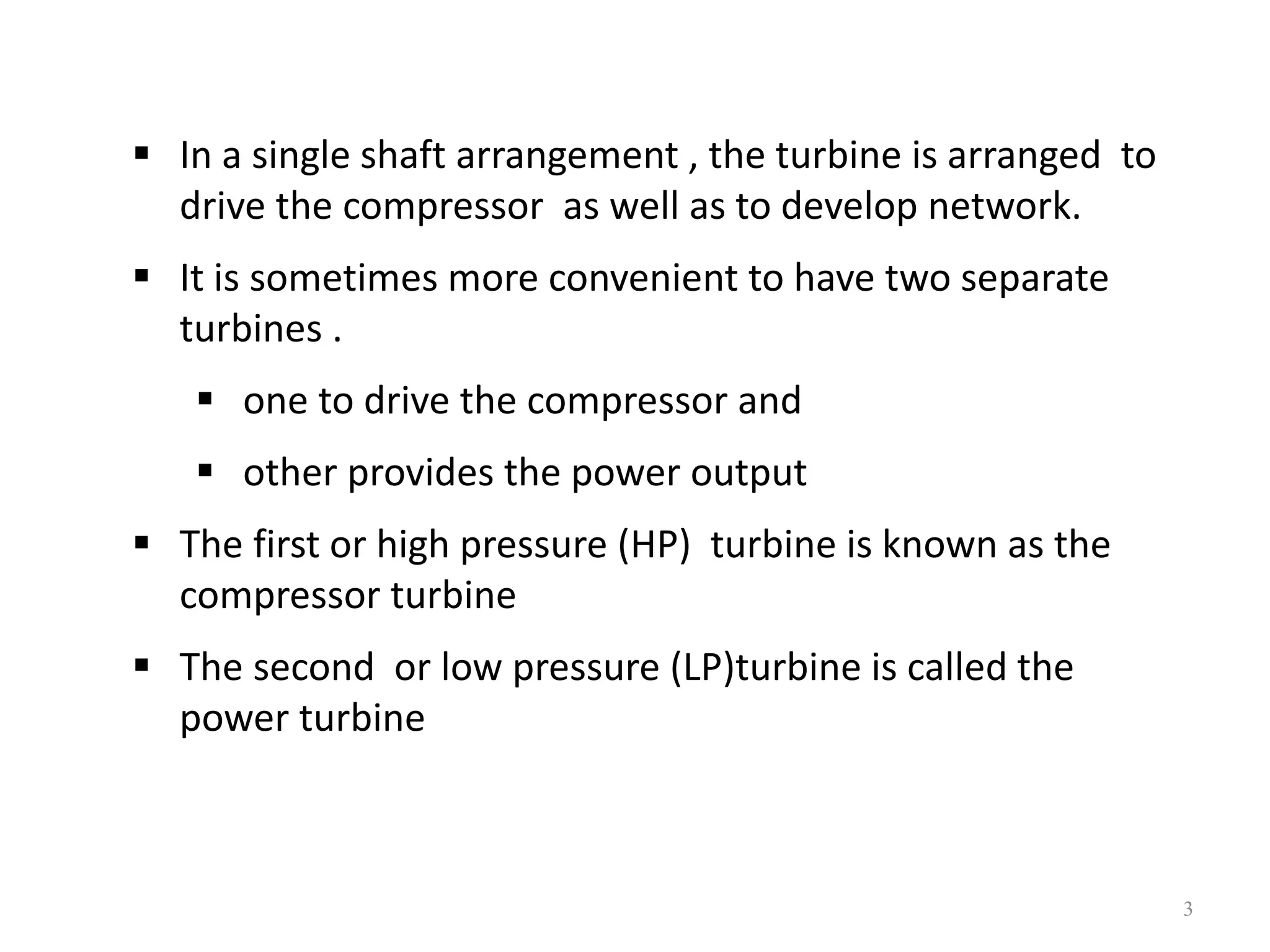

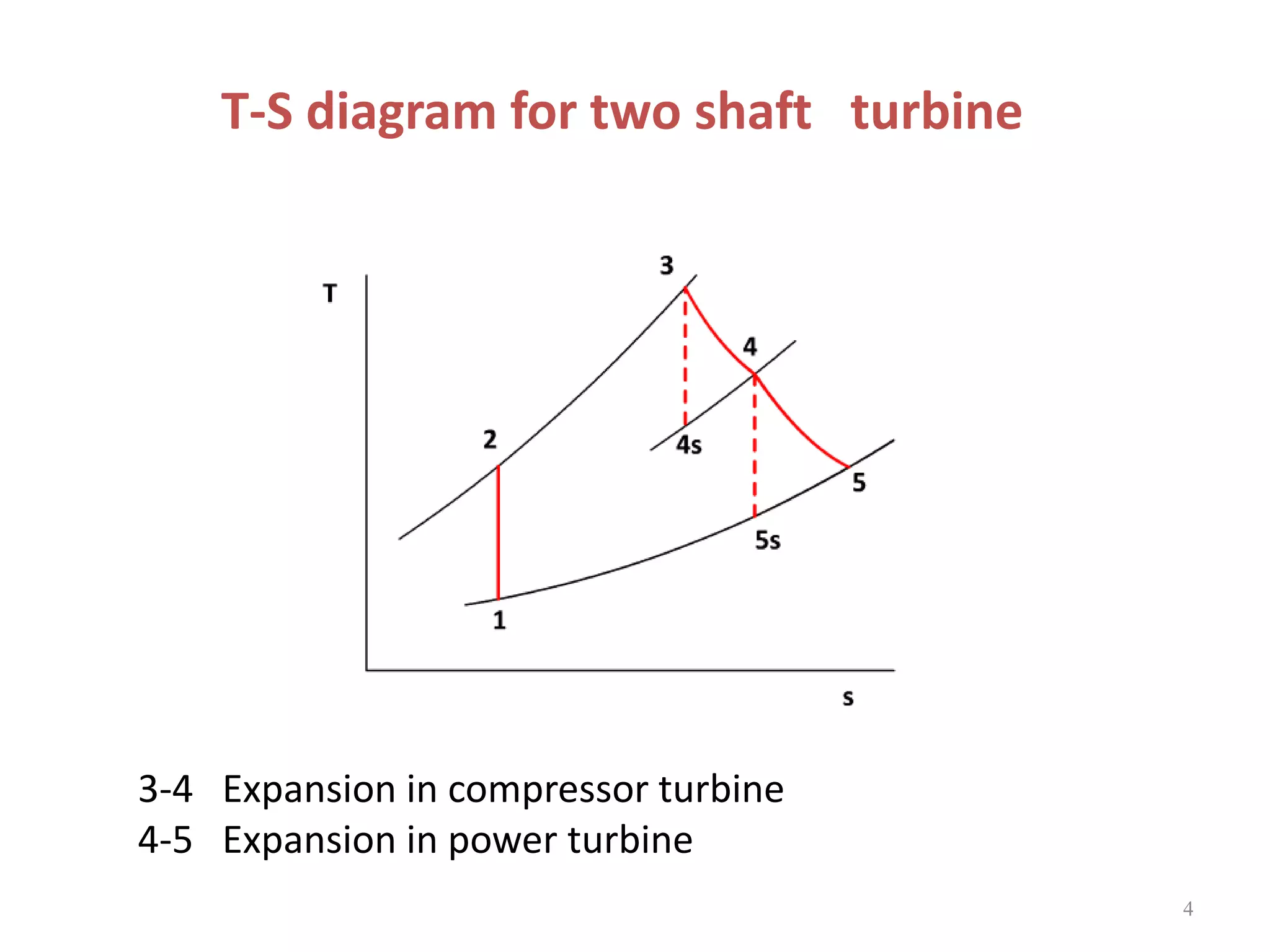

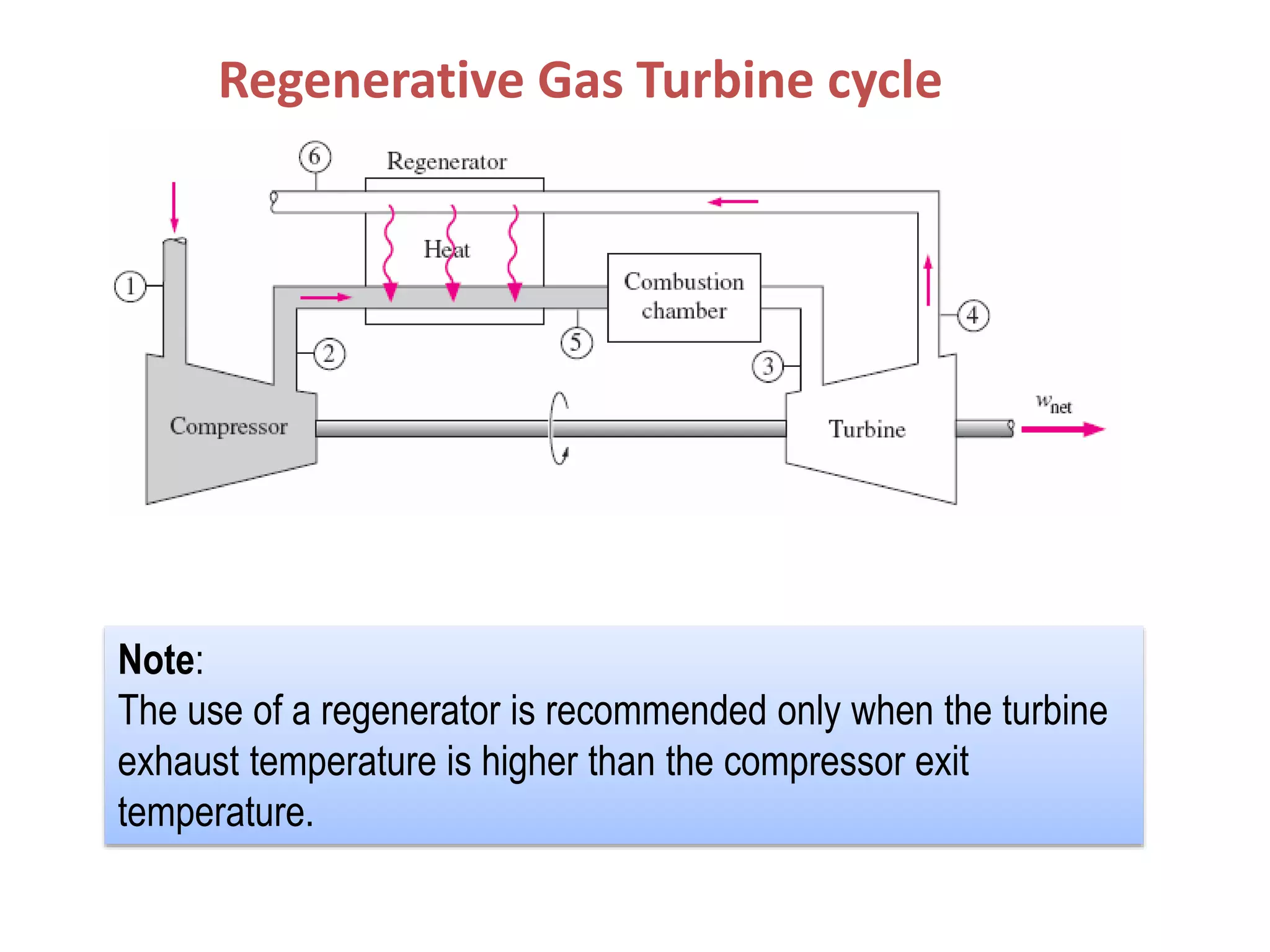

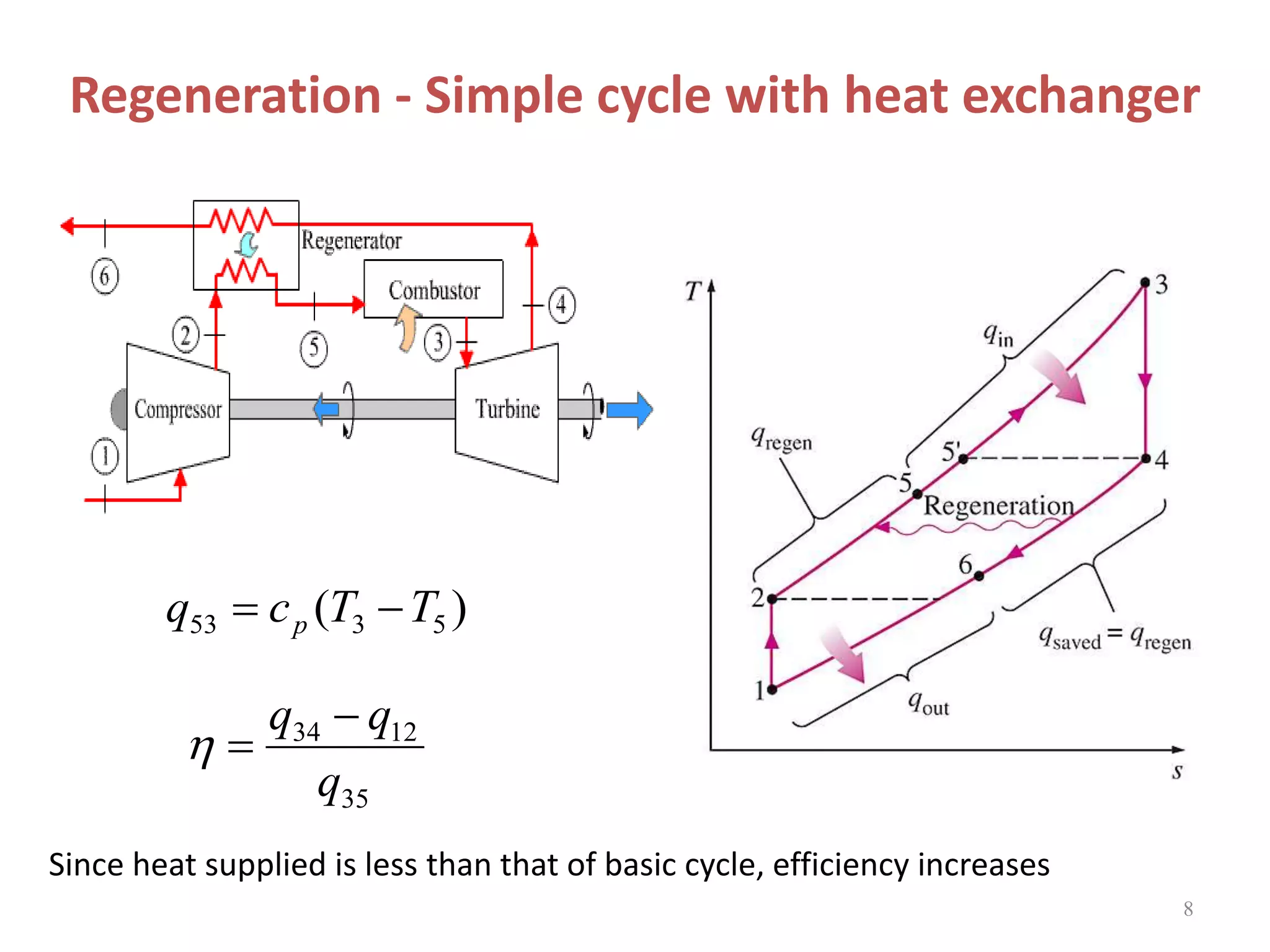

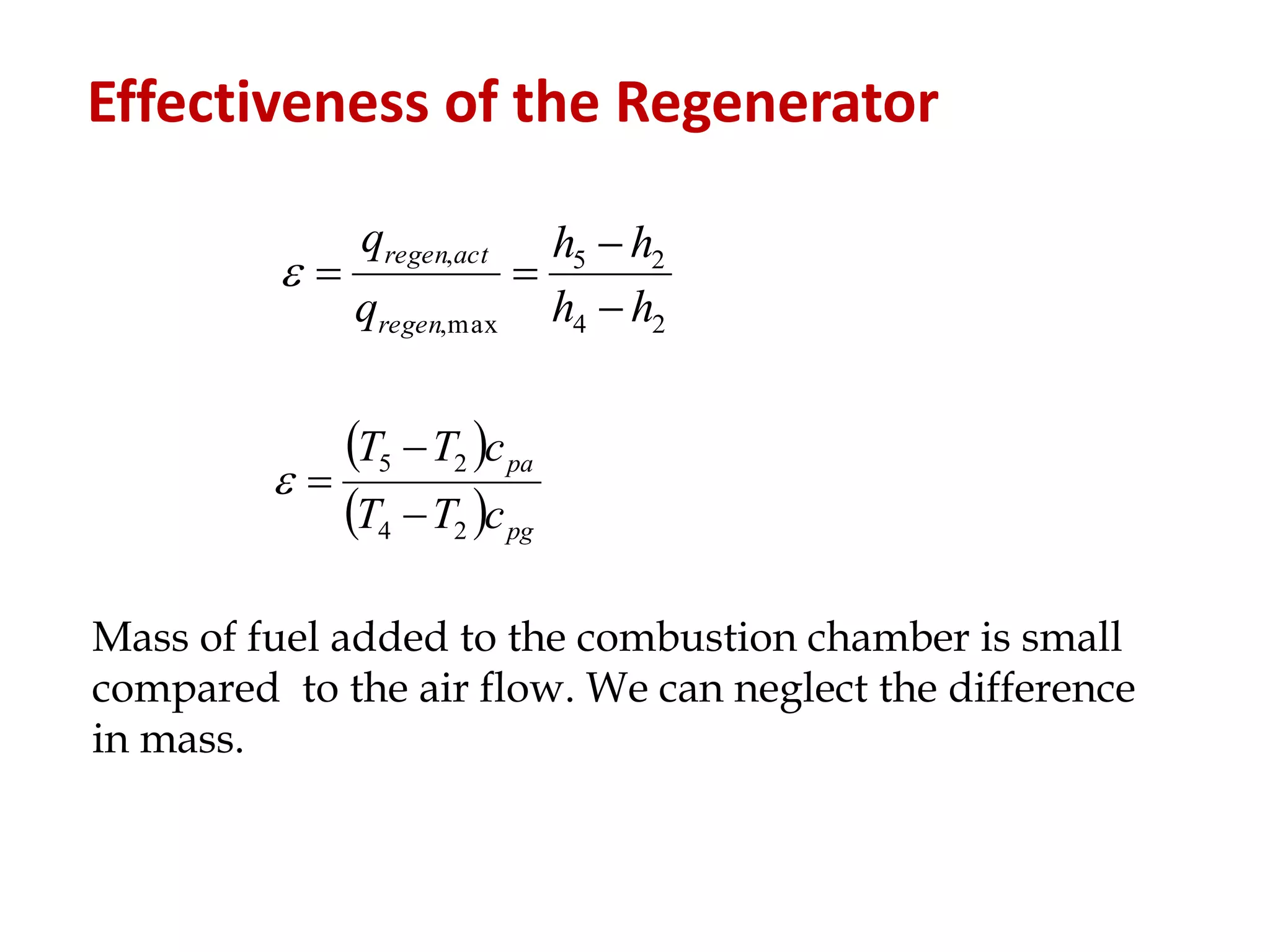

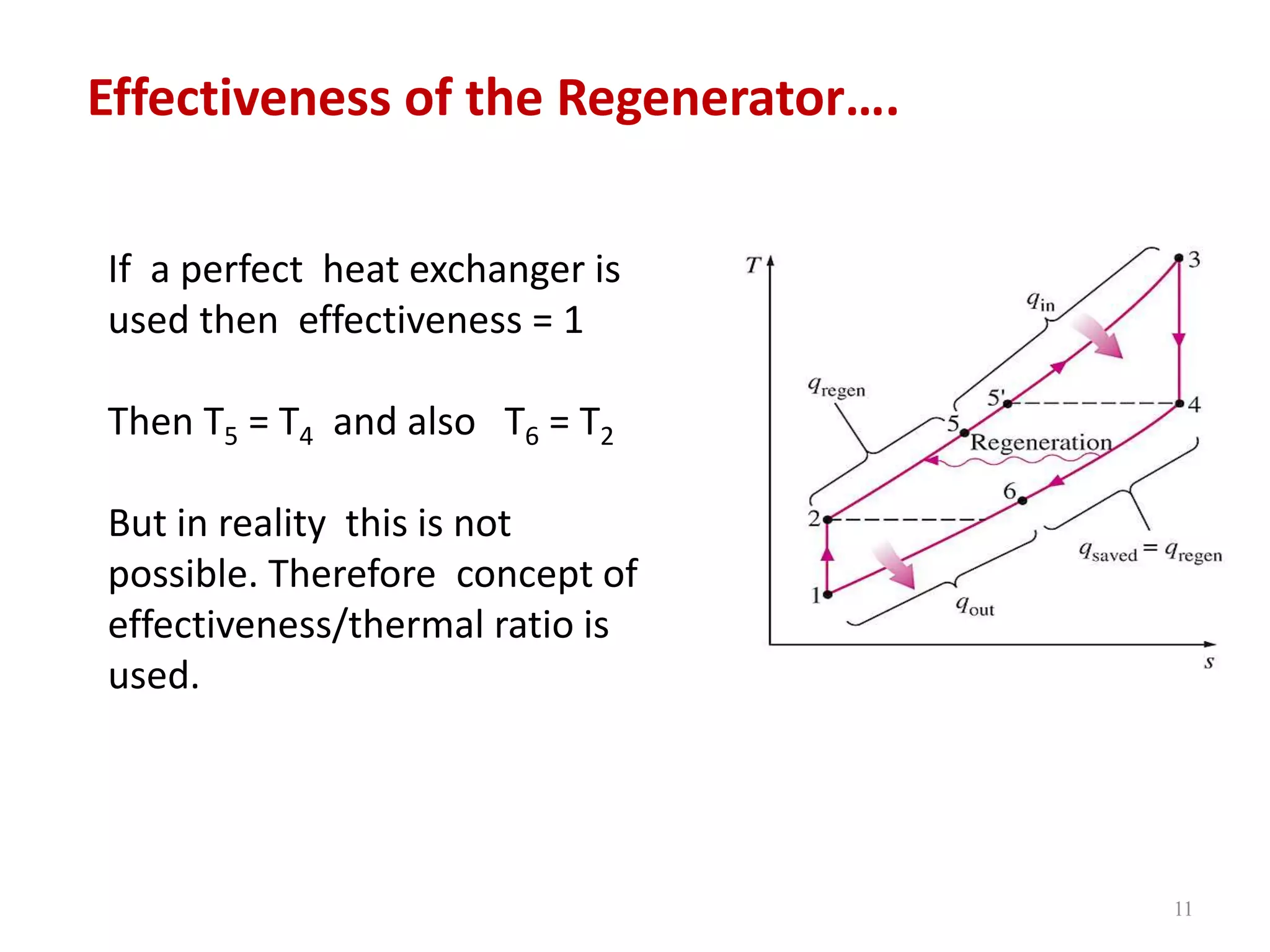

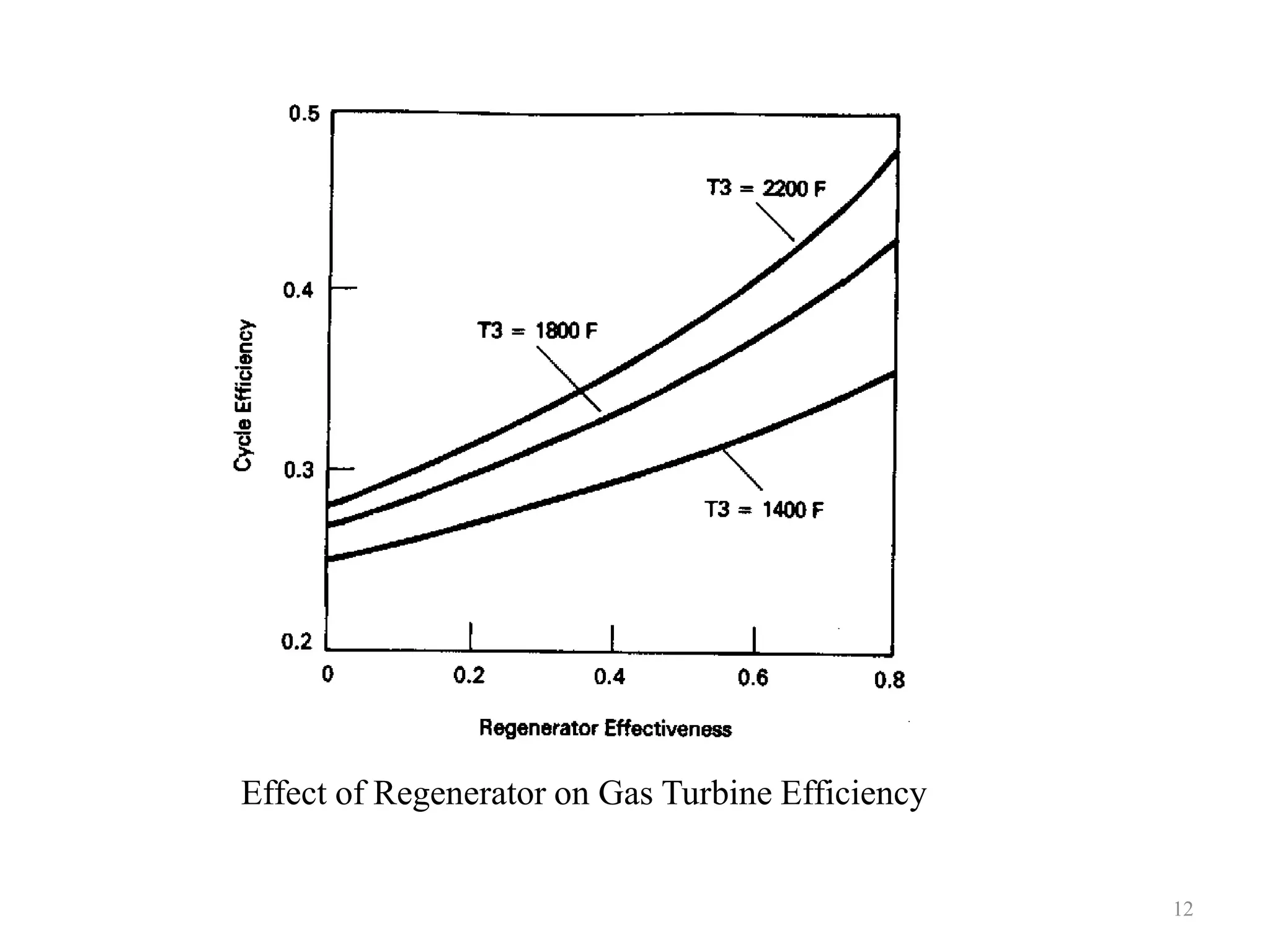

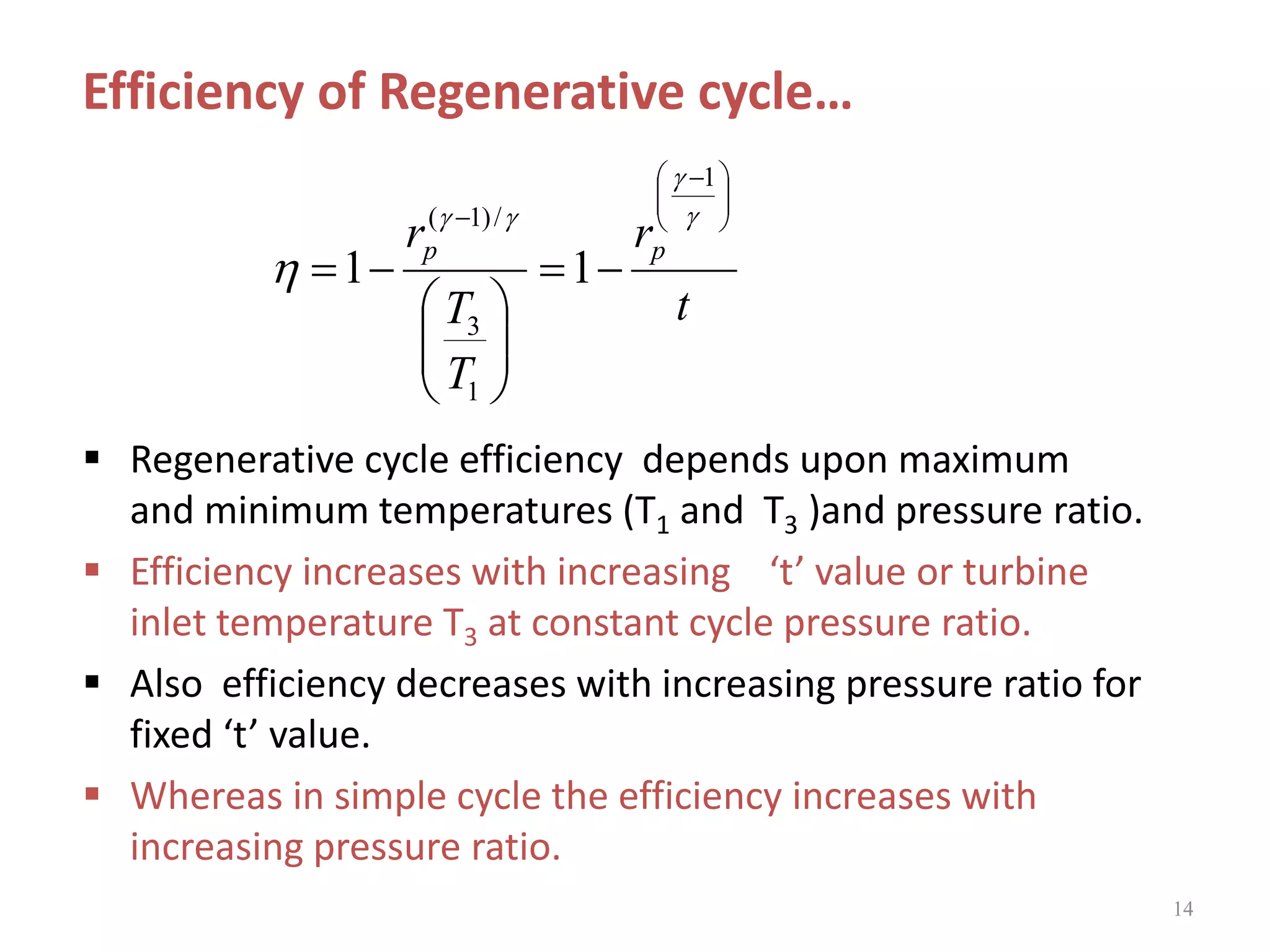

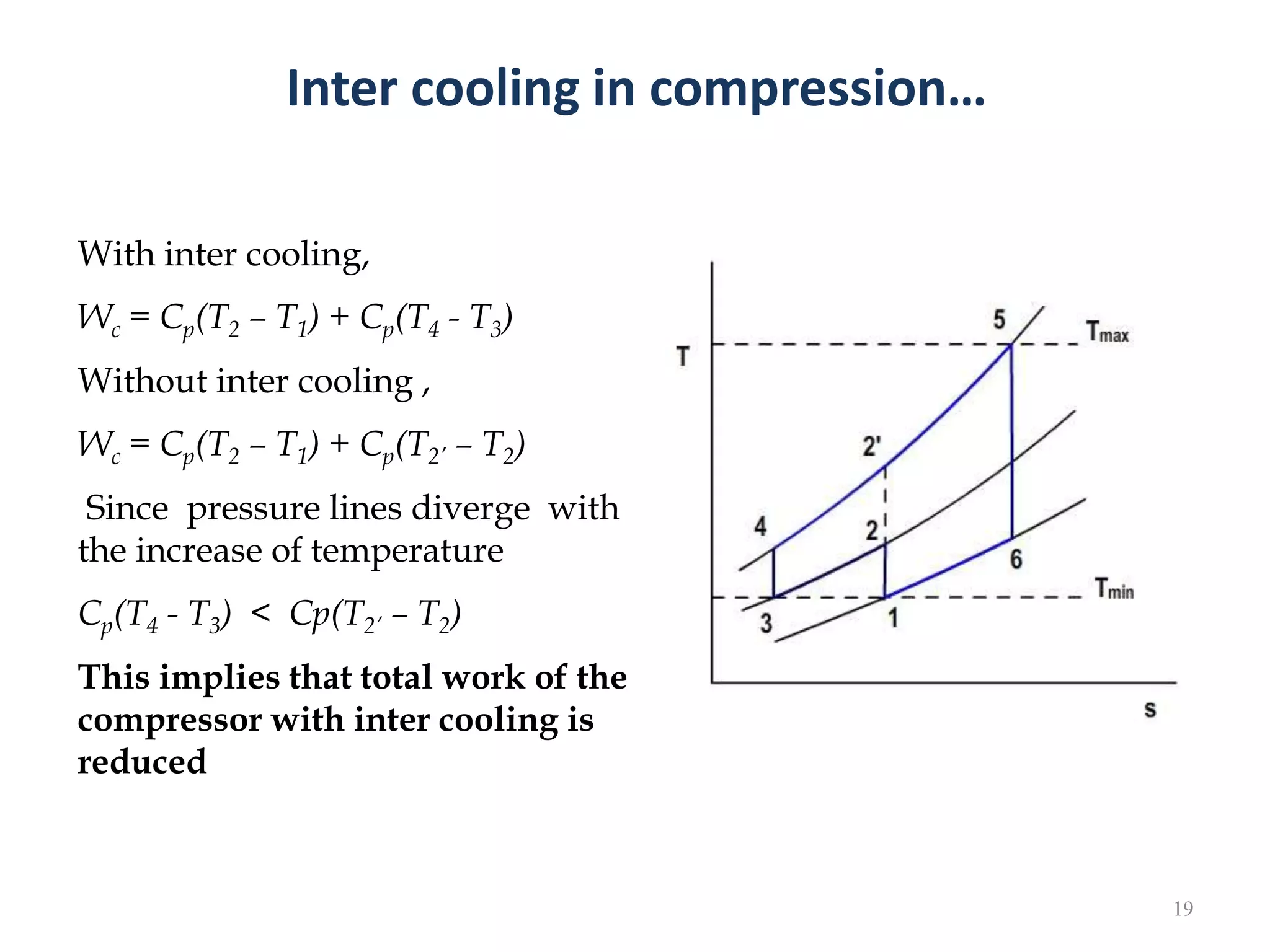

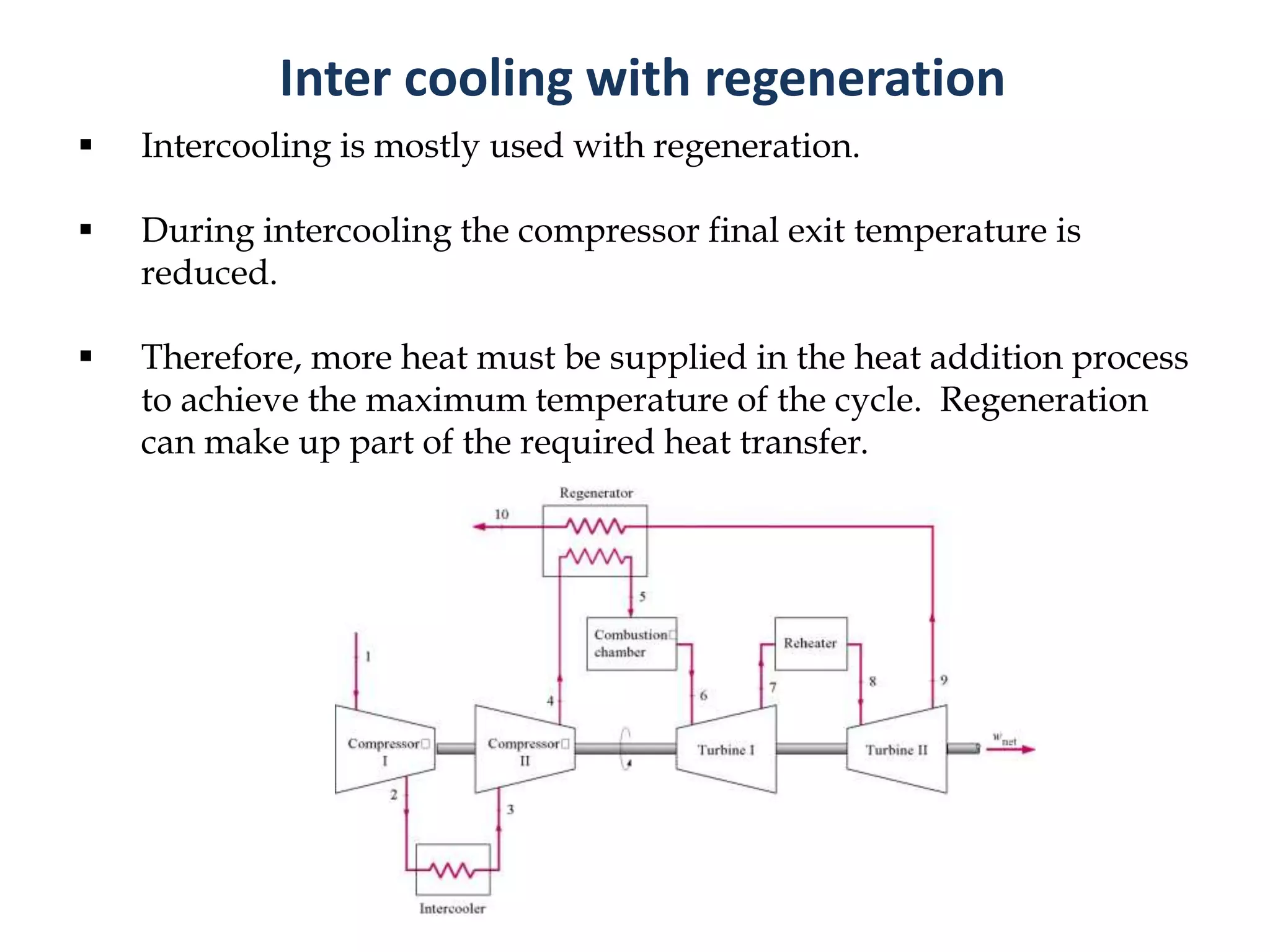

1. The document discusses gas turbine cycles with two shafts, where one turbine drives the compressor and the other provides power output. It describes regeneration using a heat exchanger to improve efficiency by heating the compressed air. Intercooling between compression stages and reheating are also discussed to reduce the work of compression. Examples are provided to calculate efficiency, power output, temperatures and pressures at different points in regenerative cycles with variations like intercooling.