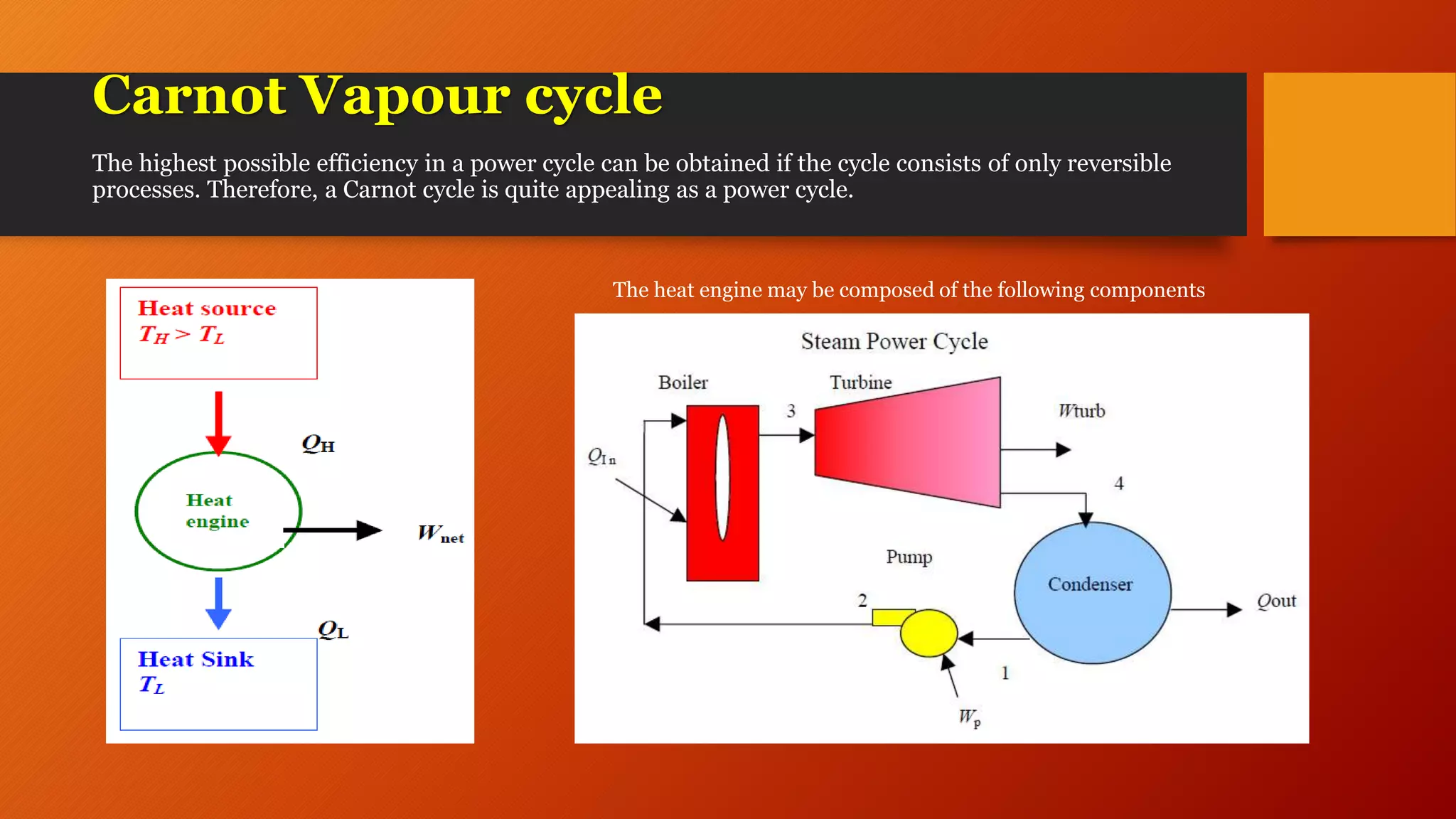

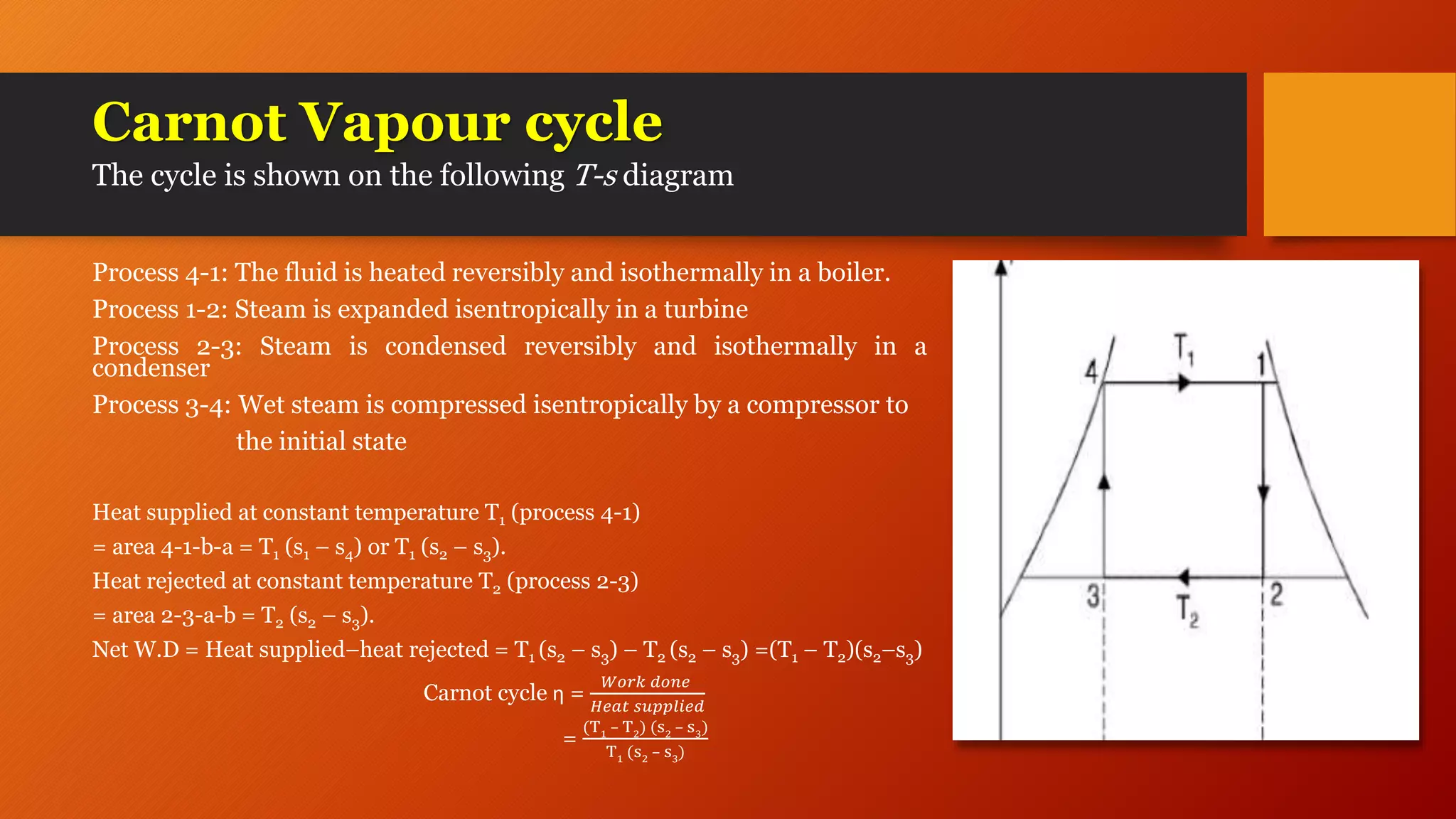

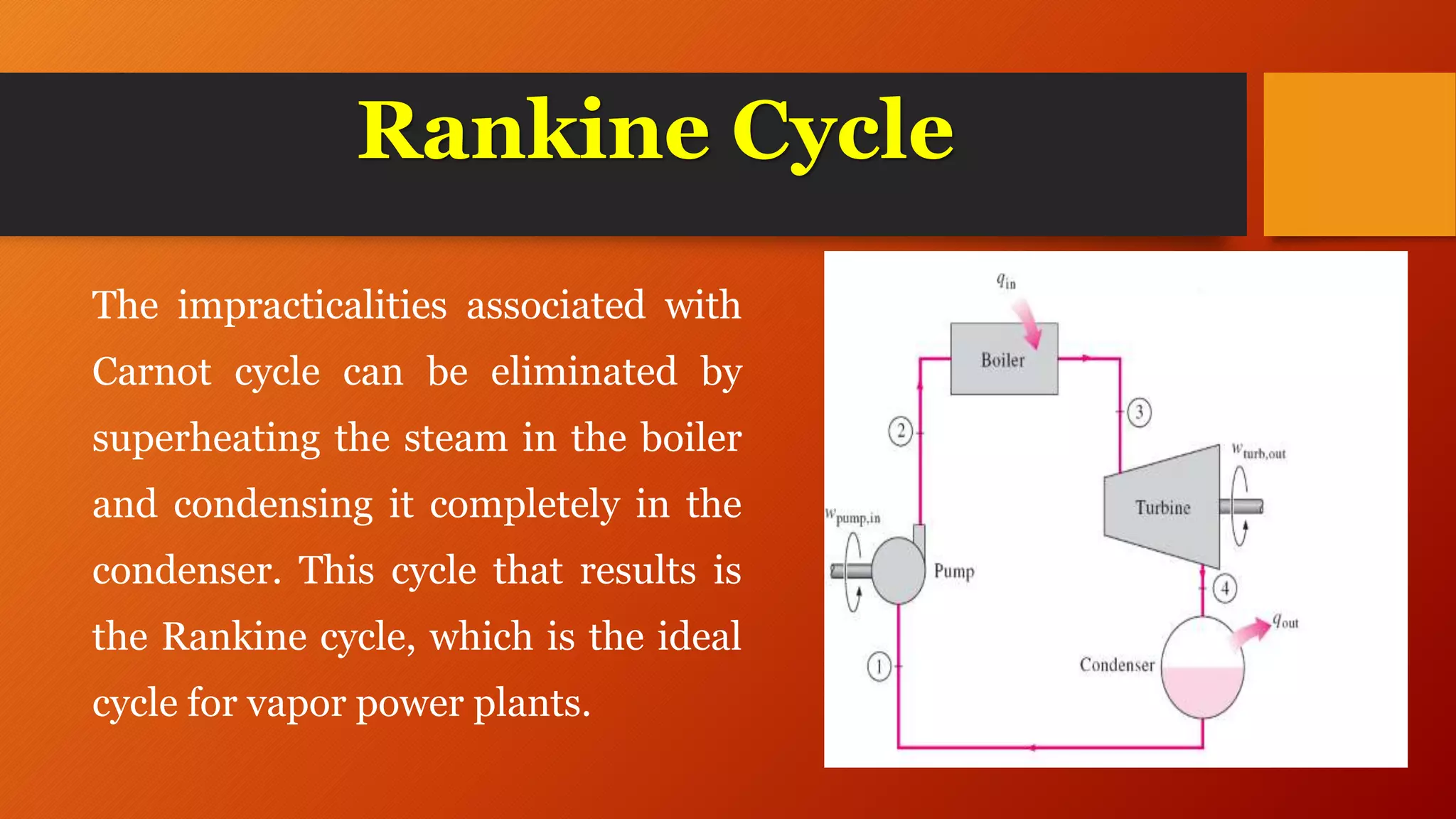

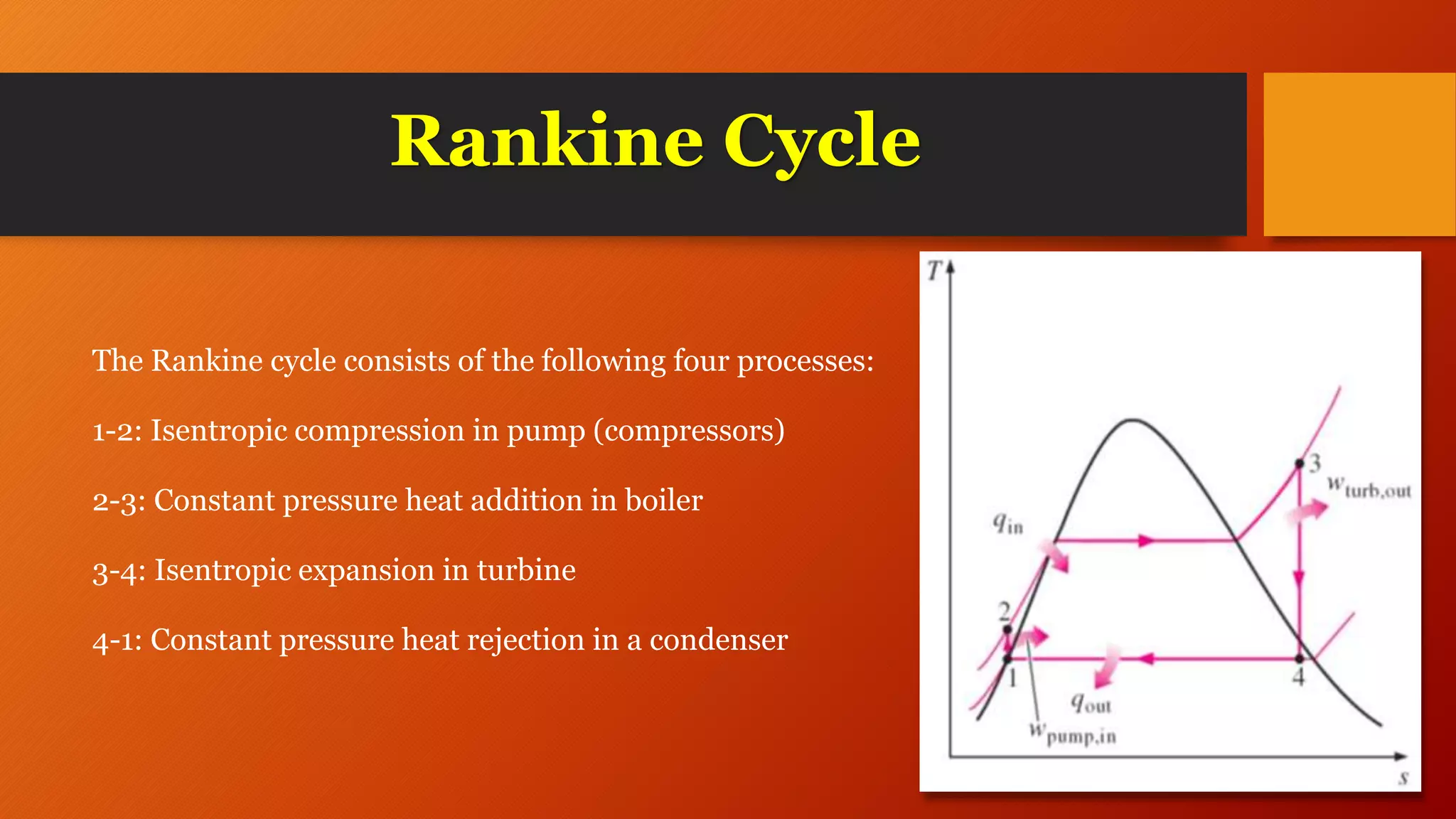

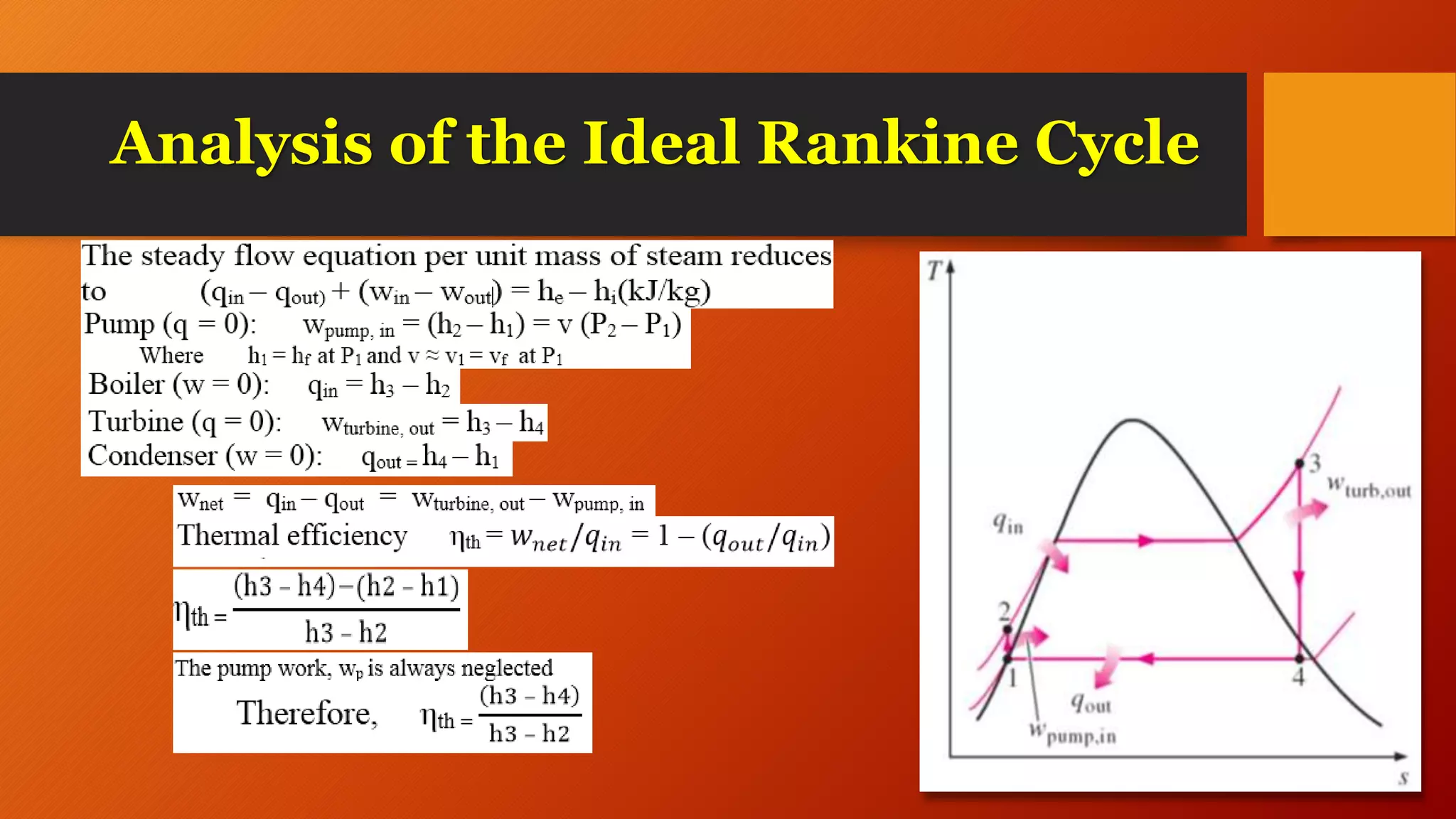

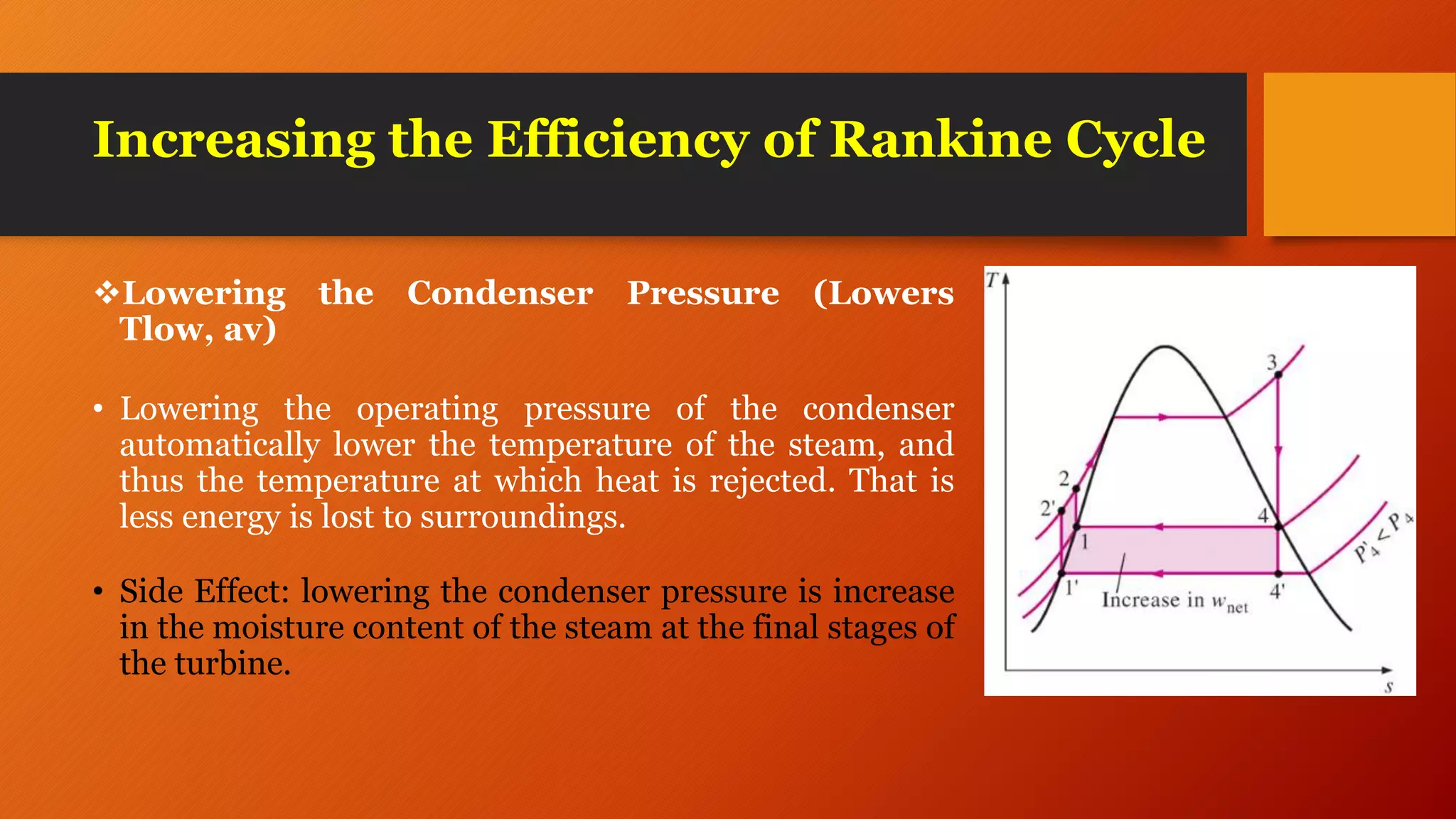

This document discusses steam power plant cycles, including ideal cycles and actual cycles. It covers the Carnot cycle, limitations of the Carnot cycle, the Rankine cycle, analysis of the ideal Rankine cycle, deviations of the actual cycle from the ideal cycle, ways to increase the efficiency of the Rankine cycle such as lowering condenser pressure, superheating steam, and increasing boiler pressure. It also discusses reheat cycles, methods of reheating such as gas reheating and live steam reheating, and regenerative cycles using open and closed feedwater heaters.