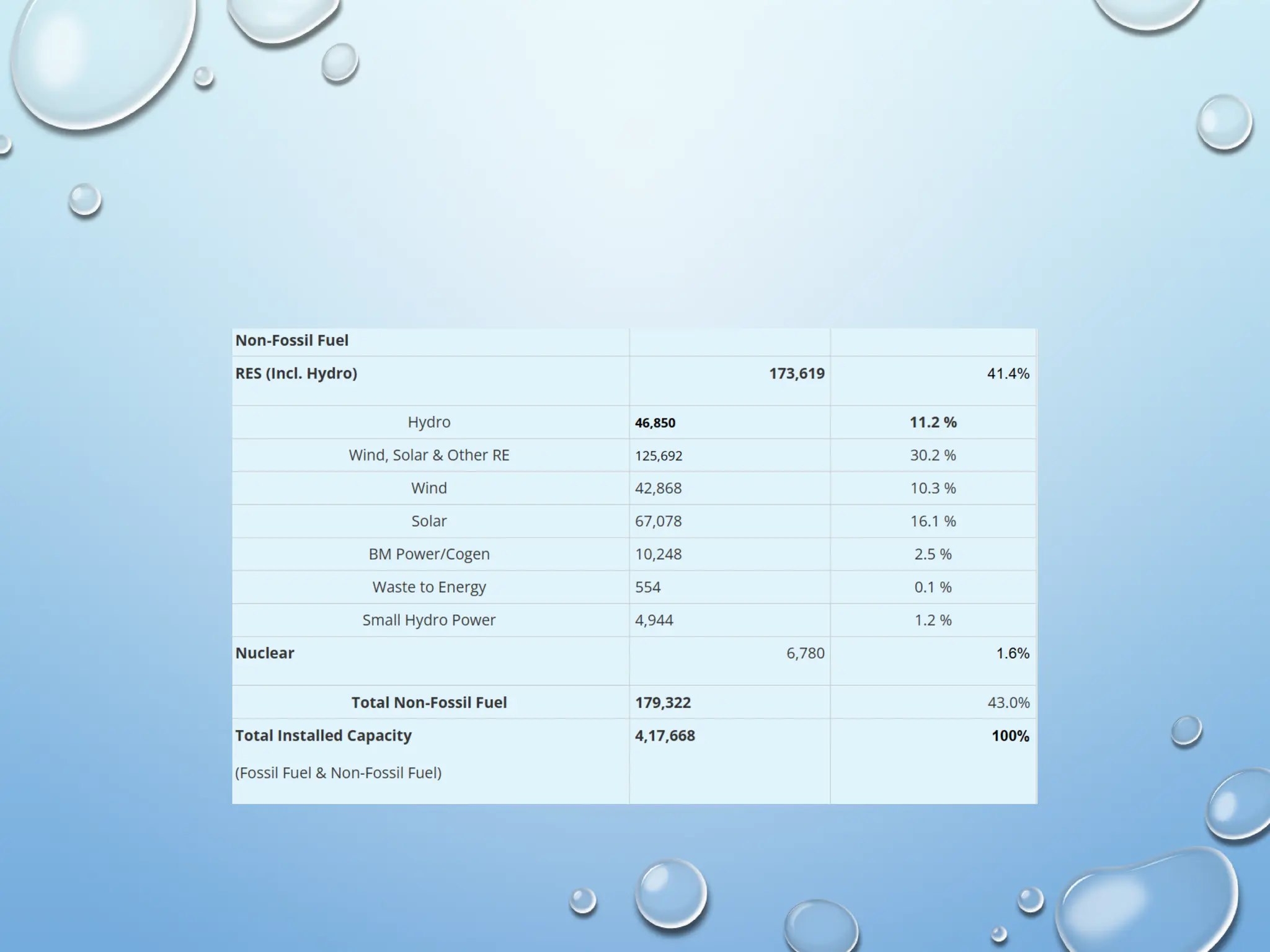

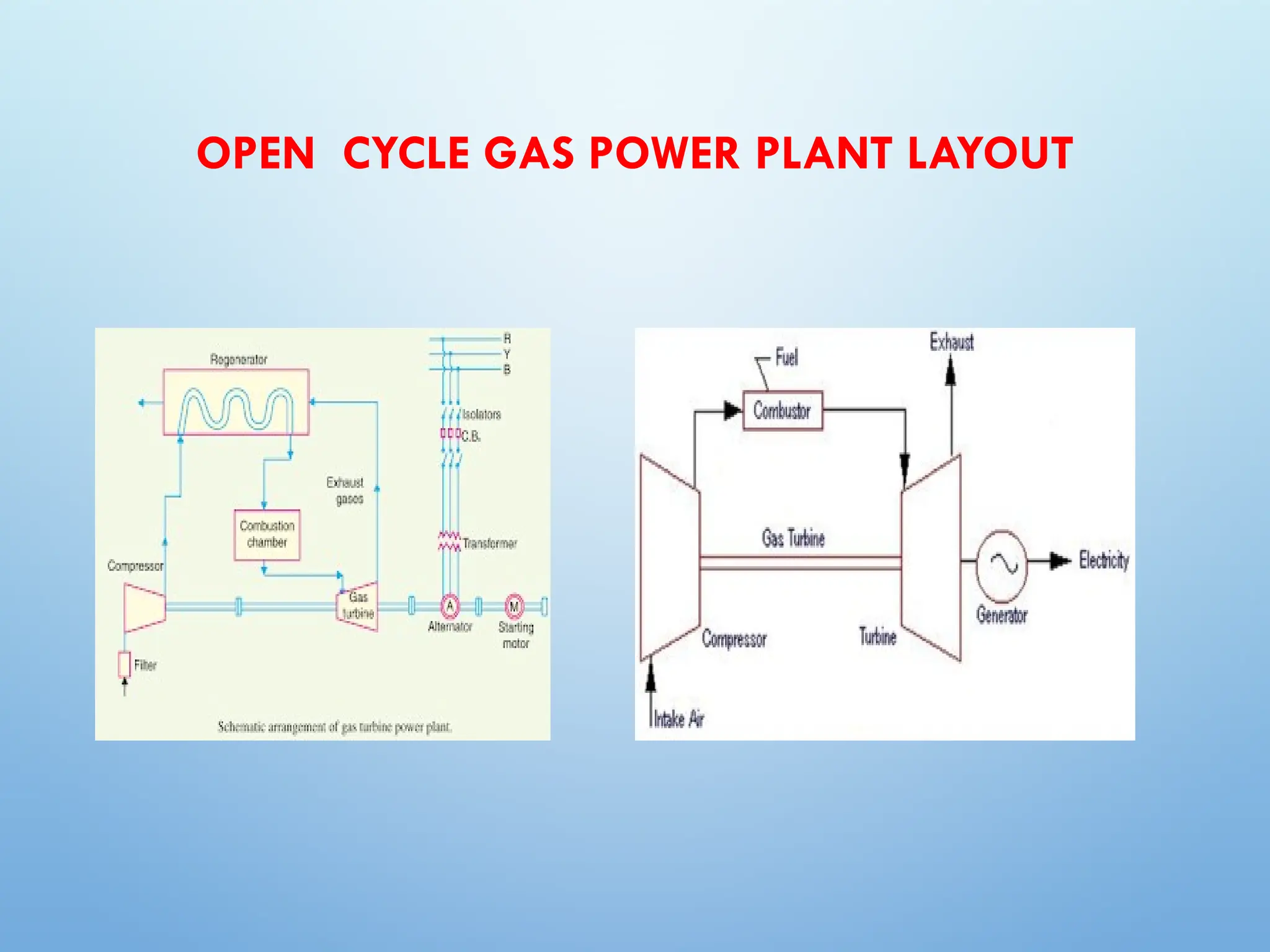

Gas-based power generation utilizes gas turbines to convert natural gas into electricity, consisting of a compressor, combustion chamber, and turbine. In India, the focus is shifting from coal to gas due to environmental concerns and limited coal reserves, with substantial investments in gas power capacity expected. Although gas power plants have lower emissions and are more efficient, they face challenges such as lower output and starting issues compared to coal plants.