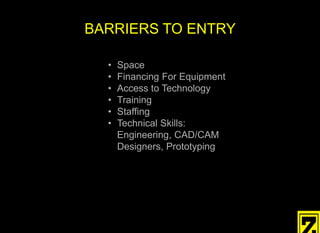

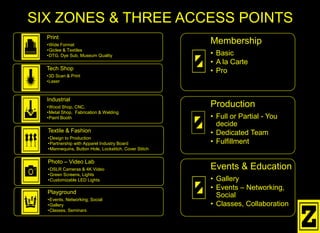

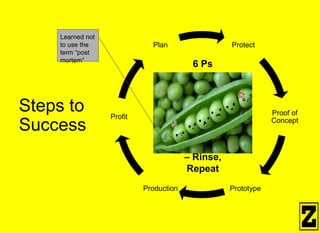

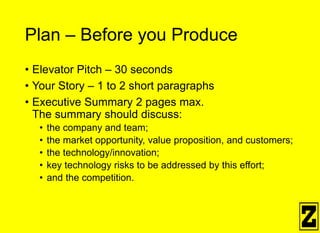

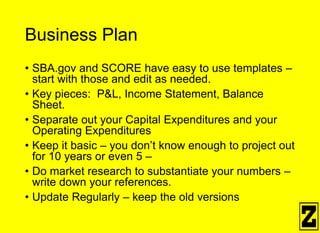

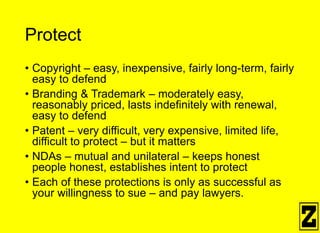

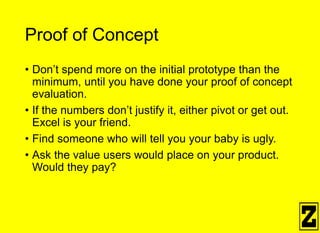

Z-Axis is a shared manufacturing space that provides equipment, technology, and training resources for inventors, designers, and small businesses. It features various zones for different types of production and membership options tailored to diverse needs. The document outlines steps for successful prototyping, production, and business planning, emphasizing the importance of market research, intellectual property protection, and iterative testing.