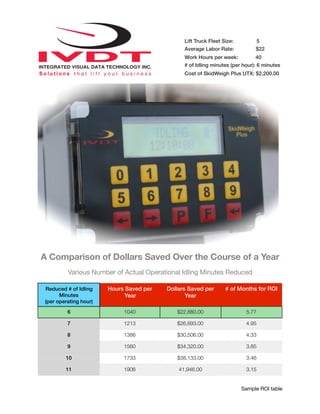

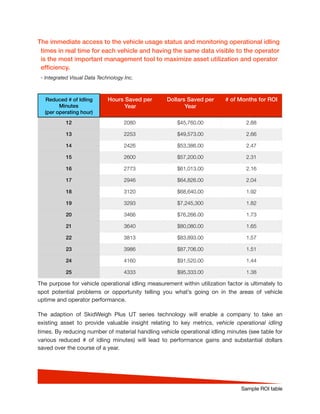

This document discusses the potential cost savings from reducing idling time of lift trucks. It provides a table showing the estimated hours and dollars saved per year and the return on investment period from reducing idling by 6-25 minutes per operating hour. Adopting a vehicle monitoring system called SkidWeigh Plus UT would provide insights into idling times and opportunities to improve performance and efficiency, saving substantial costs over the course of a year. Real-time visibility of vehicle usage status and idling times is an important management tool.