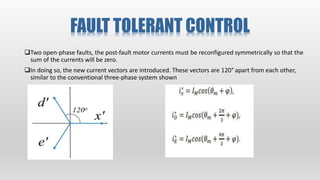

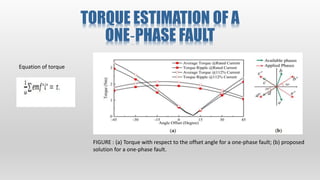

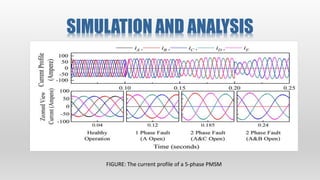

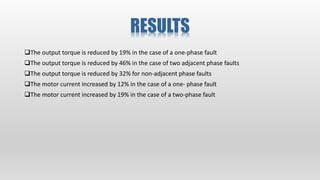

This document presents a study on fault tolerant control of a five-phase permanent magnet synchronous motor (PMSM). It discusses the basics of a 5-phase PMSM, including its advantages over other motor types. The document then examines design considerations for fault tolerance. It analyzes fault tolerant control strategies for 1-phase and 2-phase faults, including symmetric reconfiguration of currents. Methods for estimating torque under fault conditions are also presented. Simulation results show the motor is able to maintain operation under faults, though with reduced torque output. The study demonstrates effective fault tolerant control solutions to allow indefinite operation of a 5-phase PMSM even when faults occur.