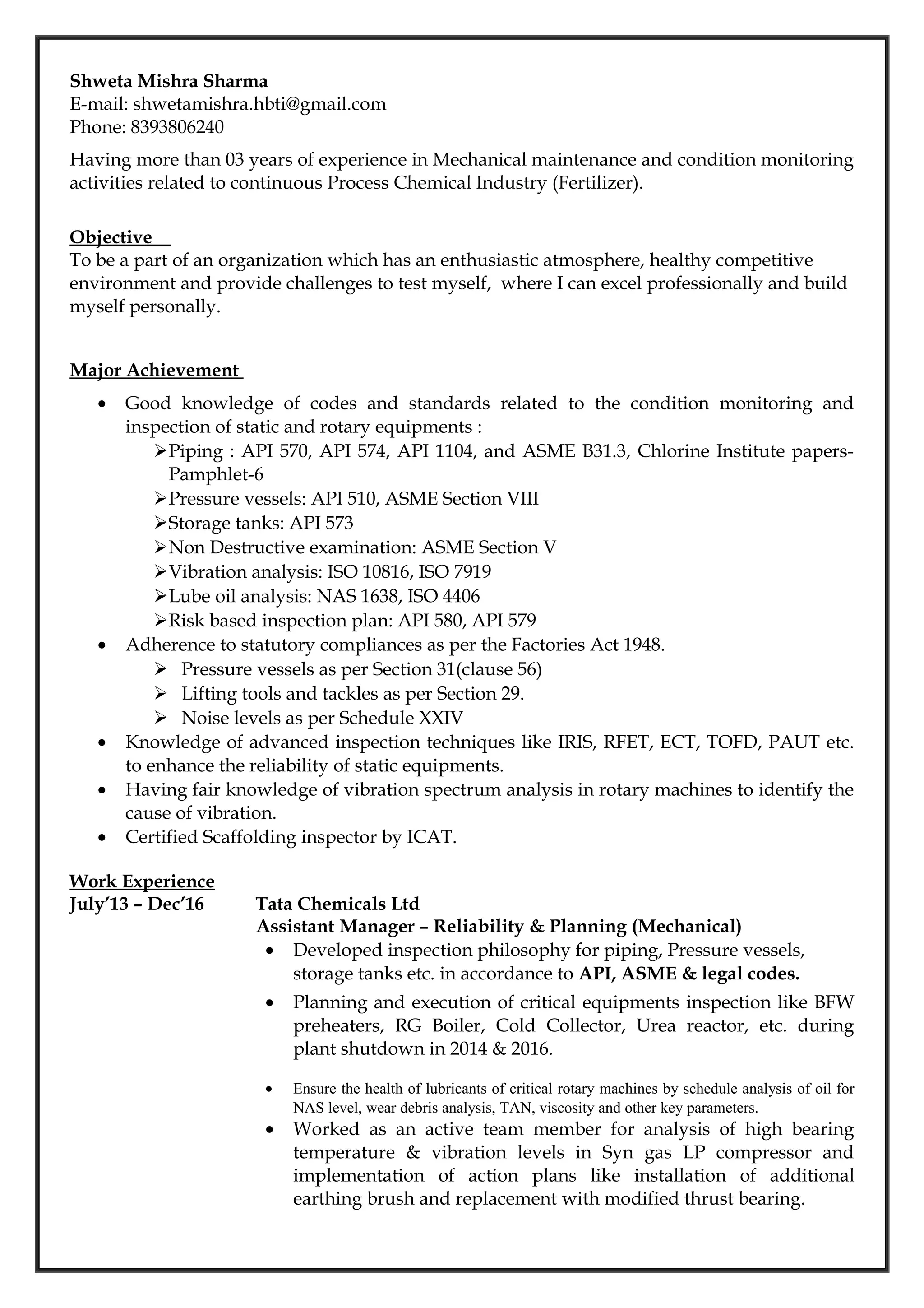

Shweta Mishra Sharma seeks a position that provides challenges and opportunities for professional and personal growth. She has over 3 years of experience in mechanical maintenance and condition monitoring for a chemical plant. She developed inspection programs for critical equipment adhering to codes and standards. She led teams performing inspections using various non-destructive testing techniques and ensured regulatory compliance. She has knowledge of vibration analysis, lubrication analysis, and predictive maintenance techniques.