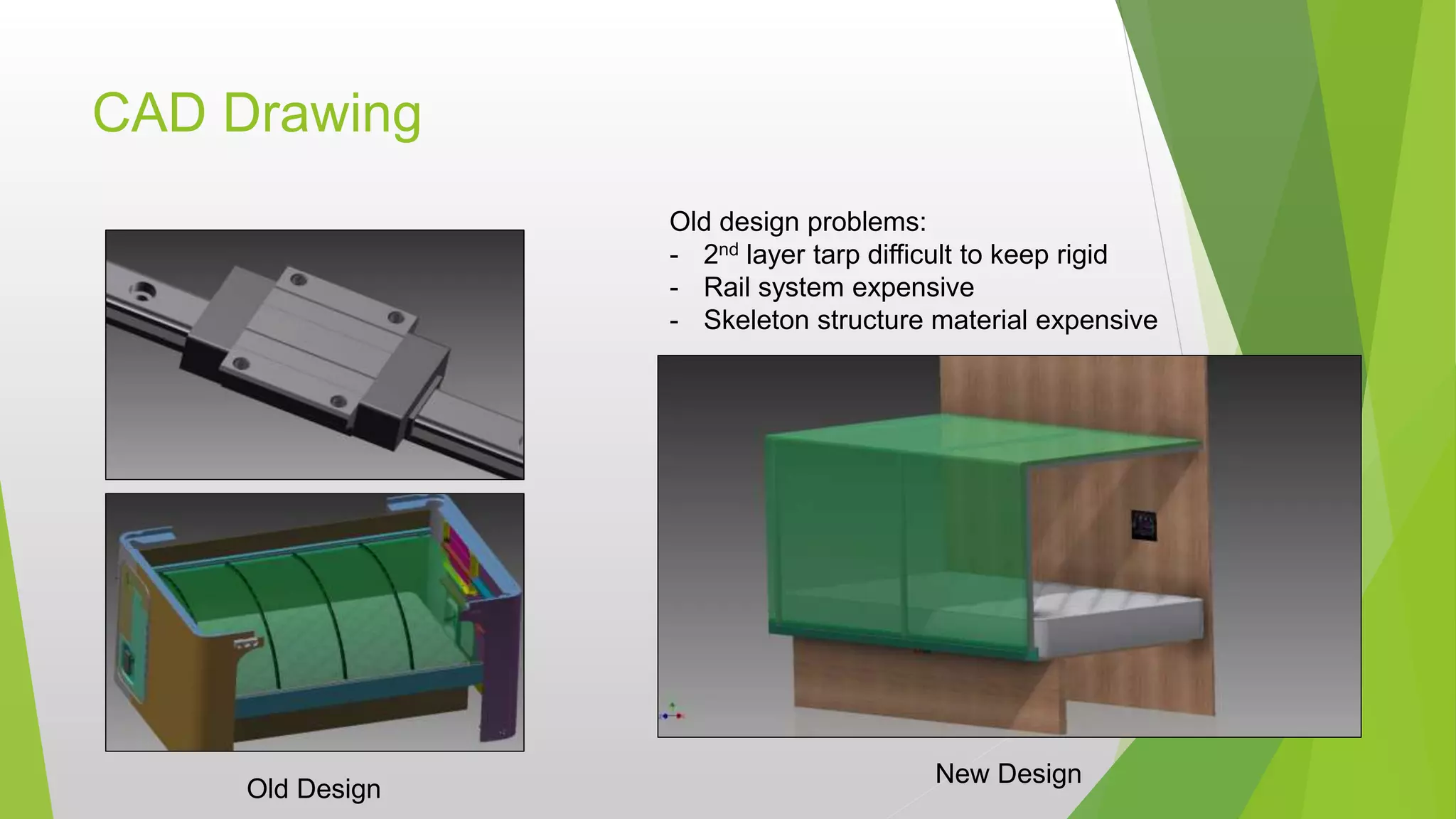

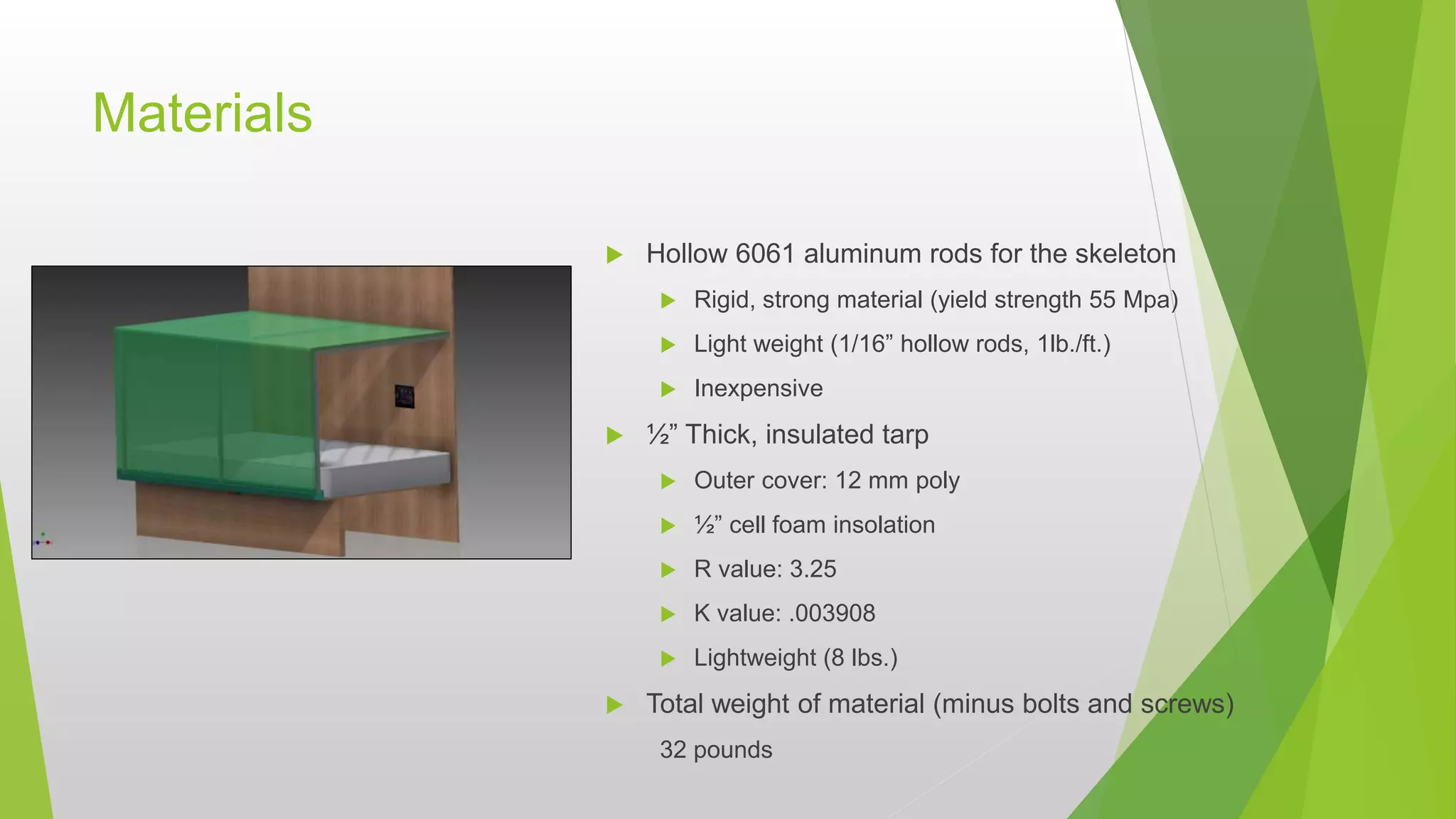

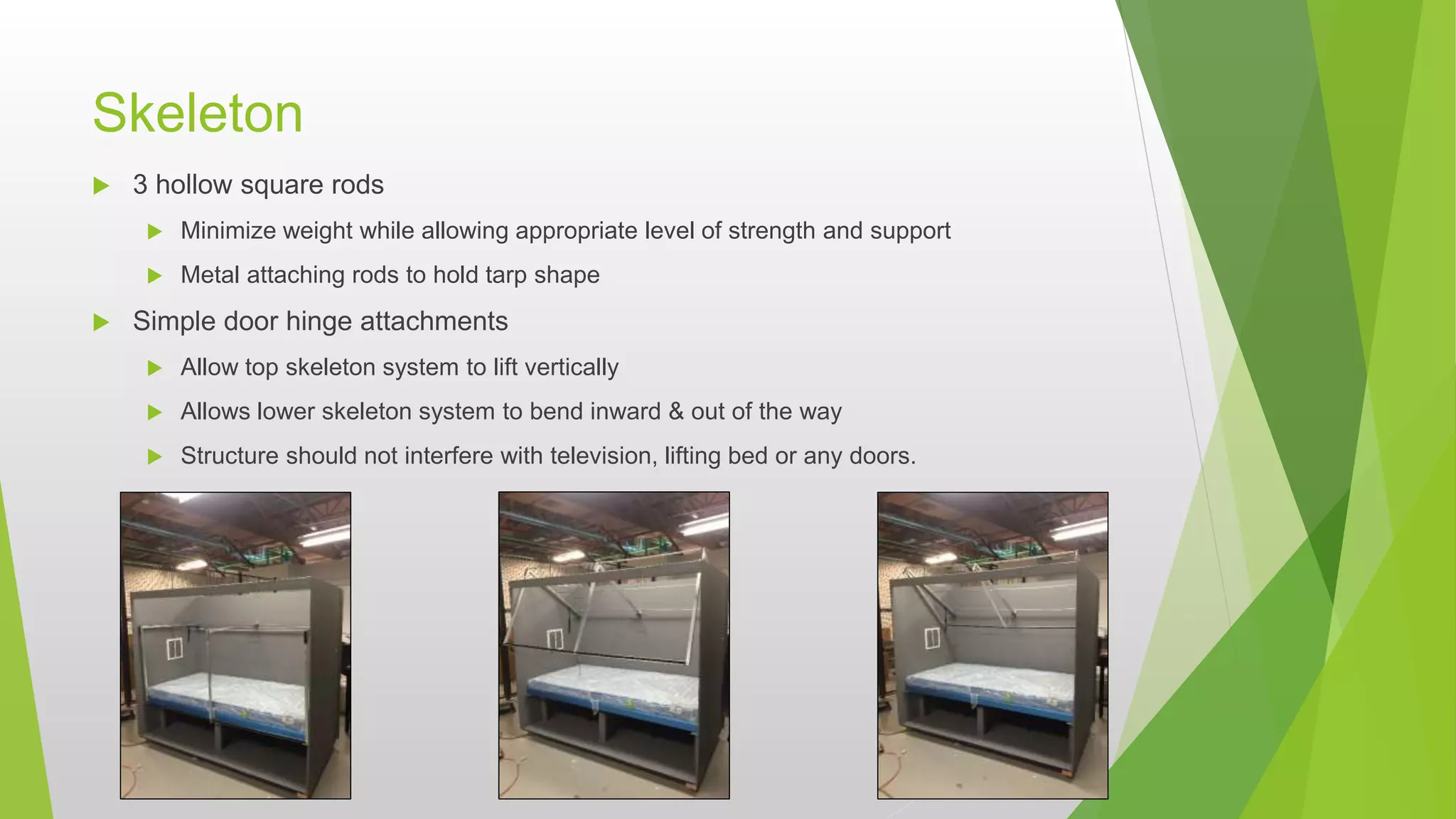

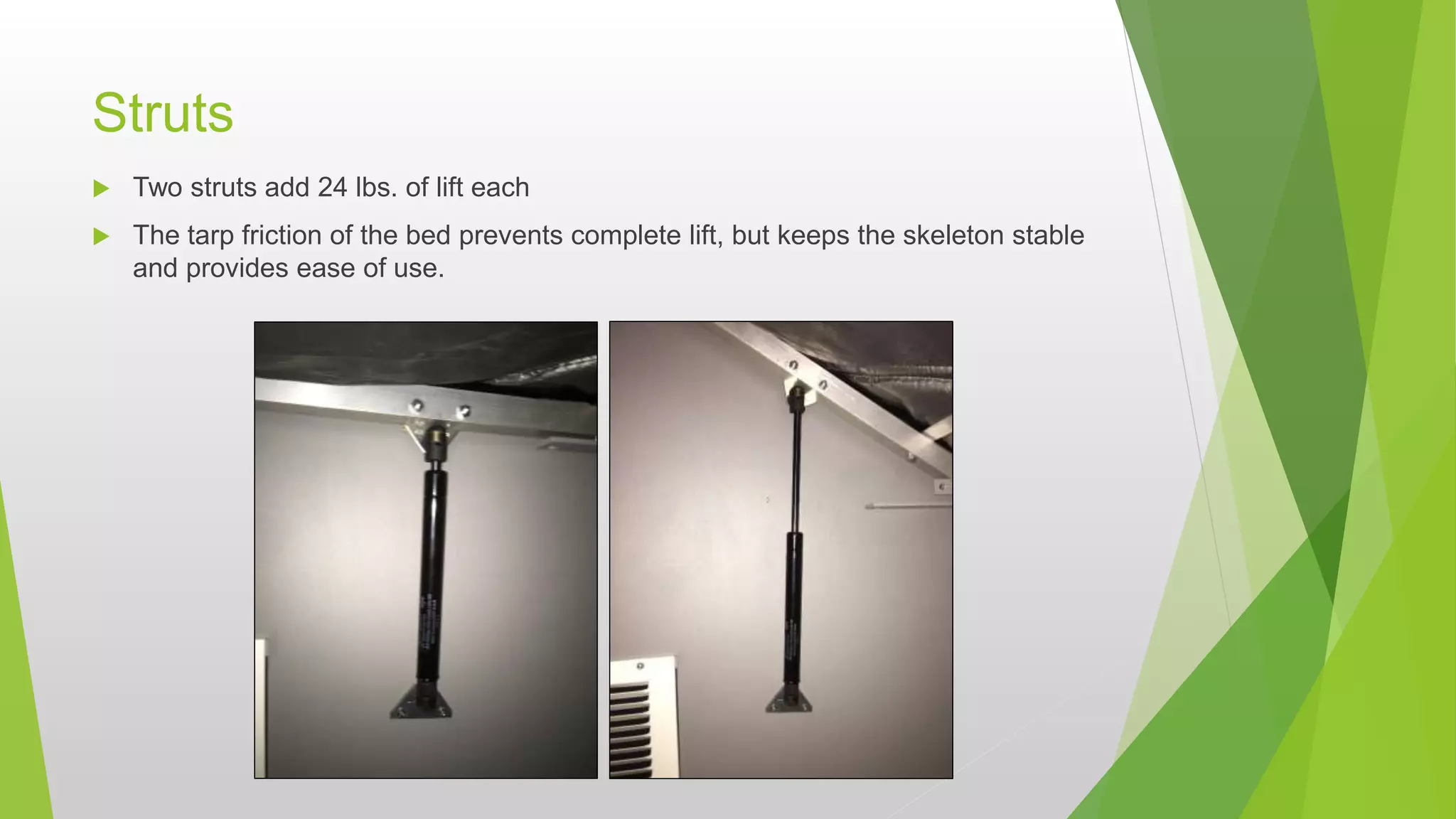

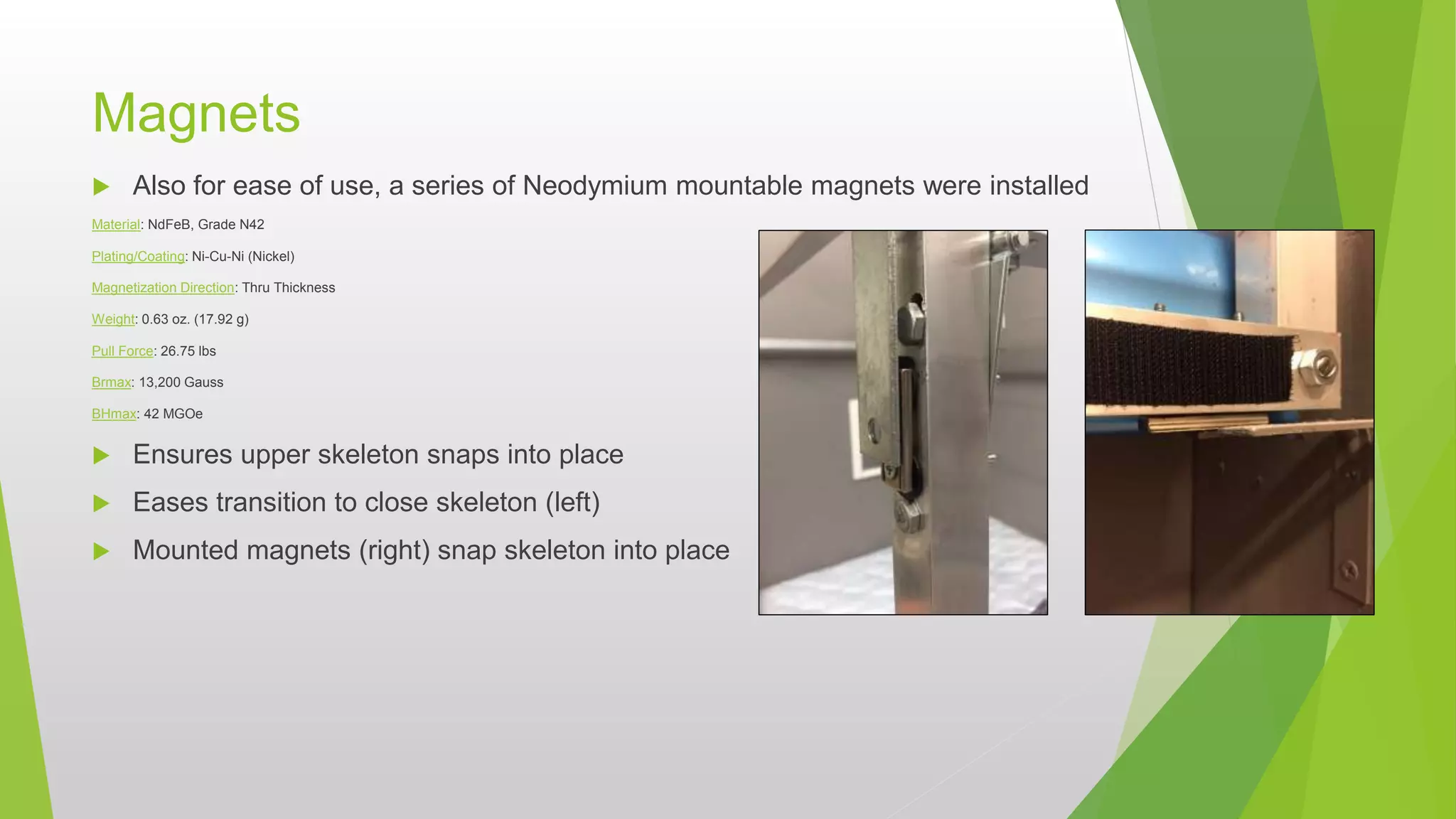

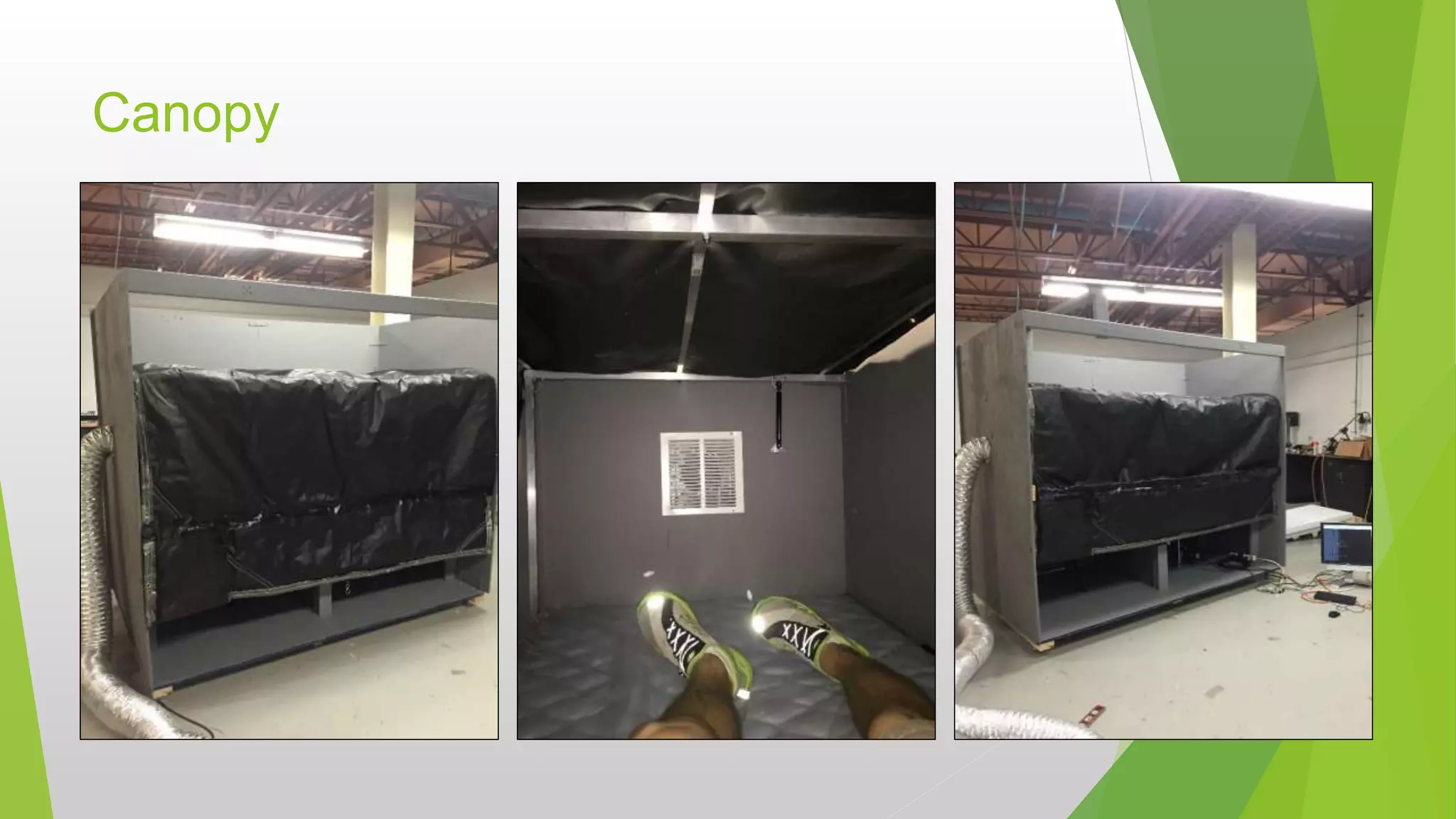

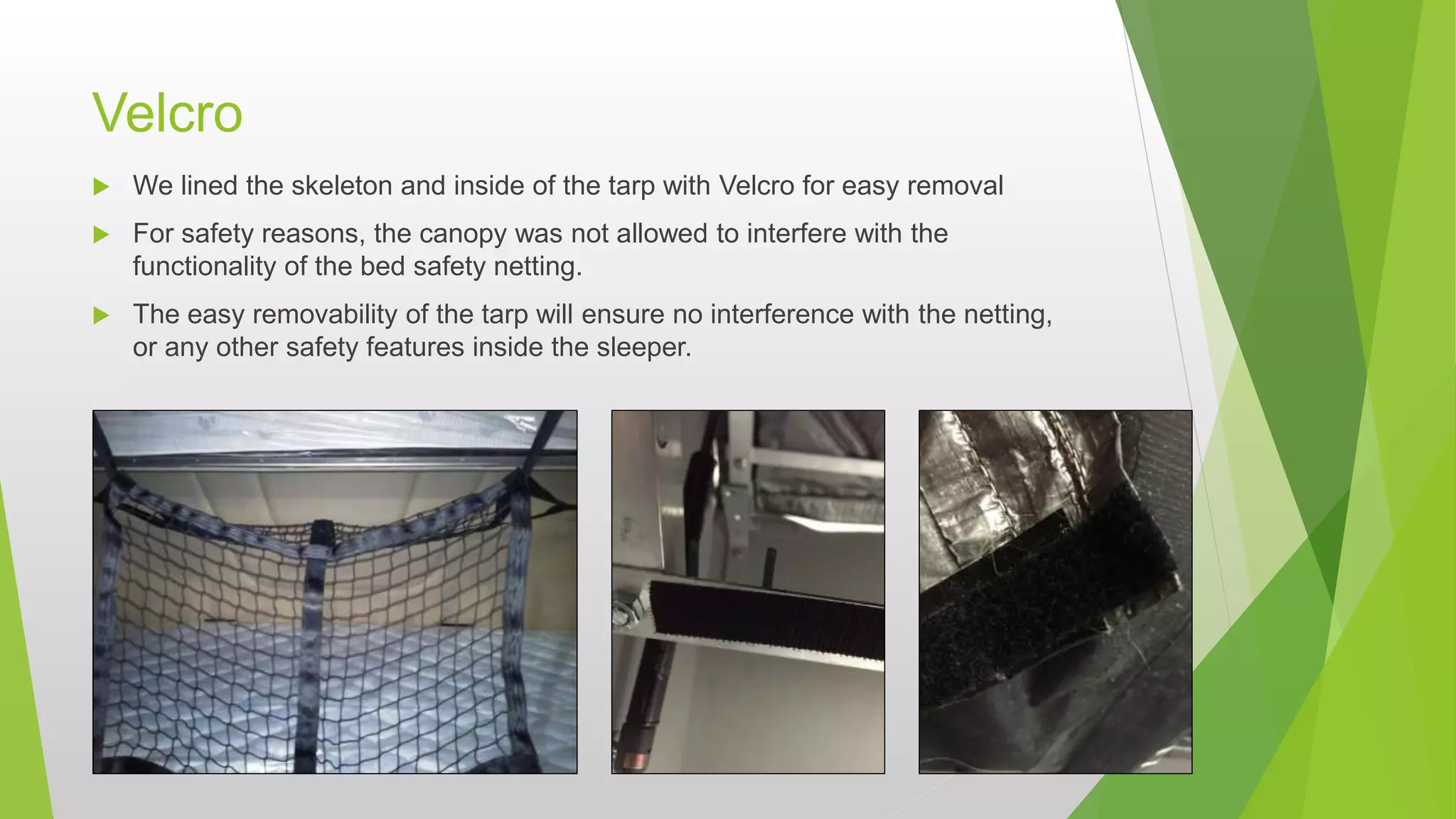

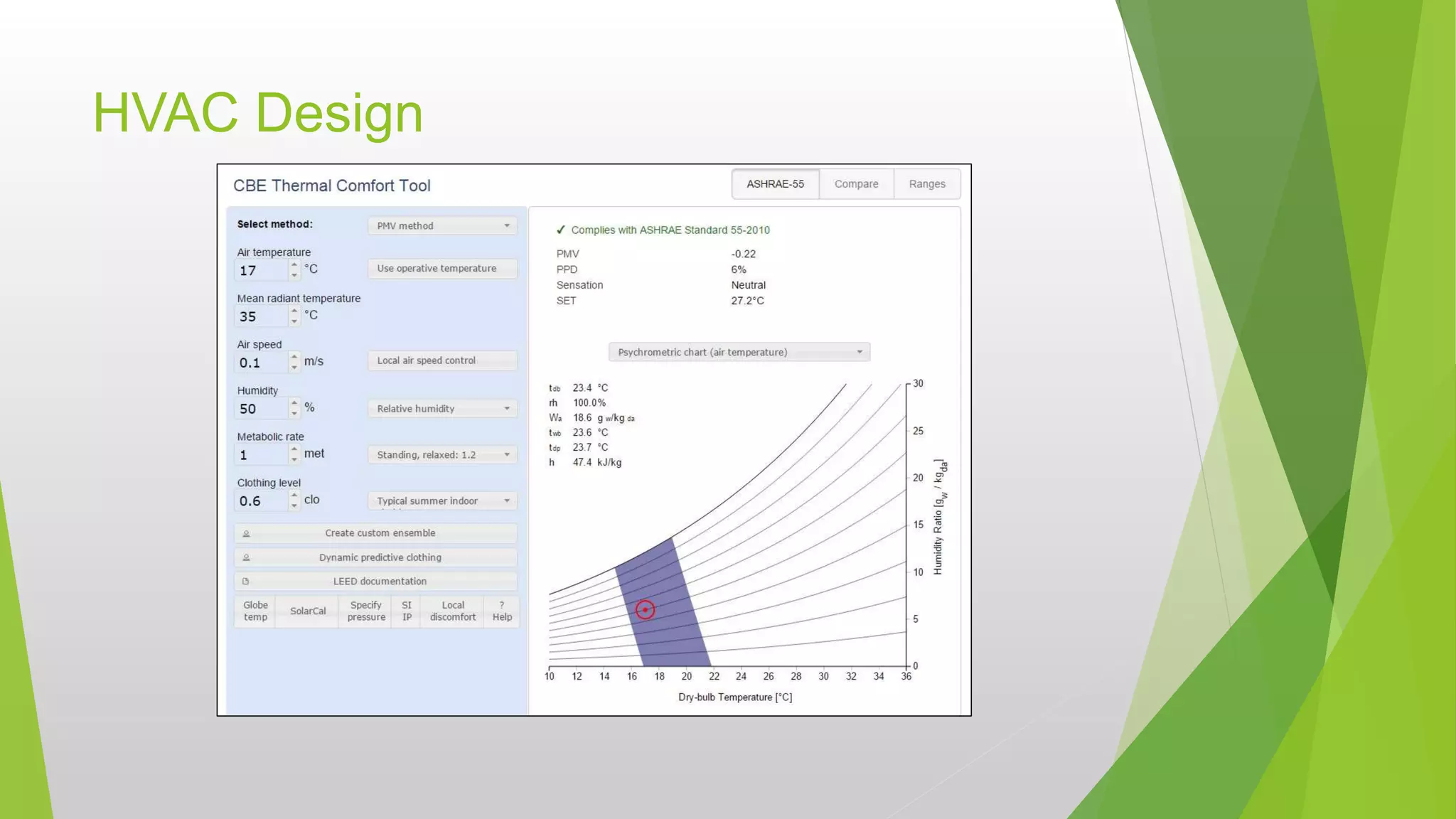

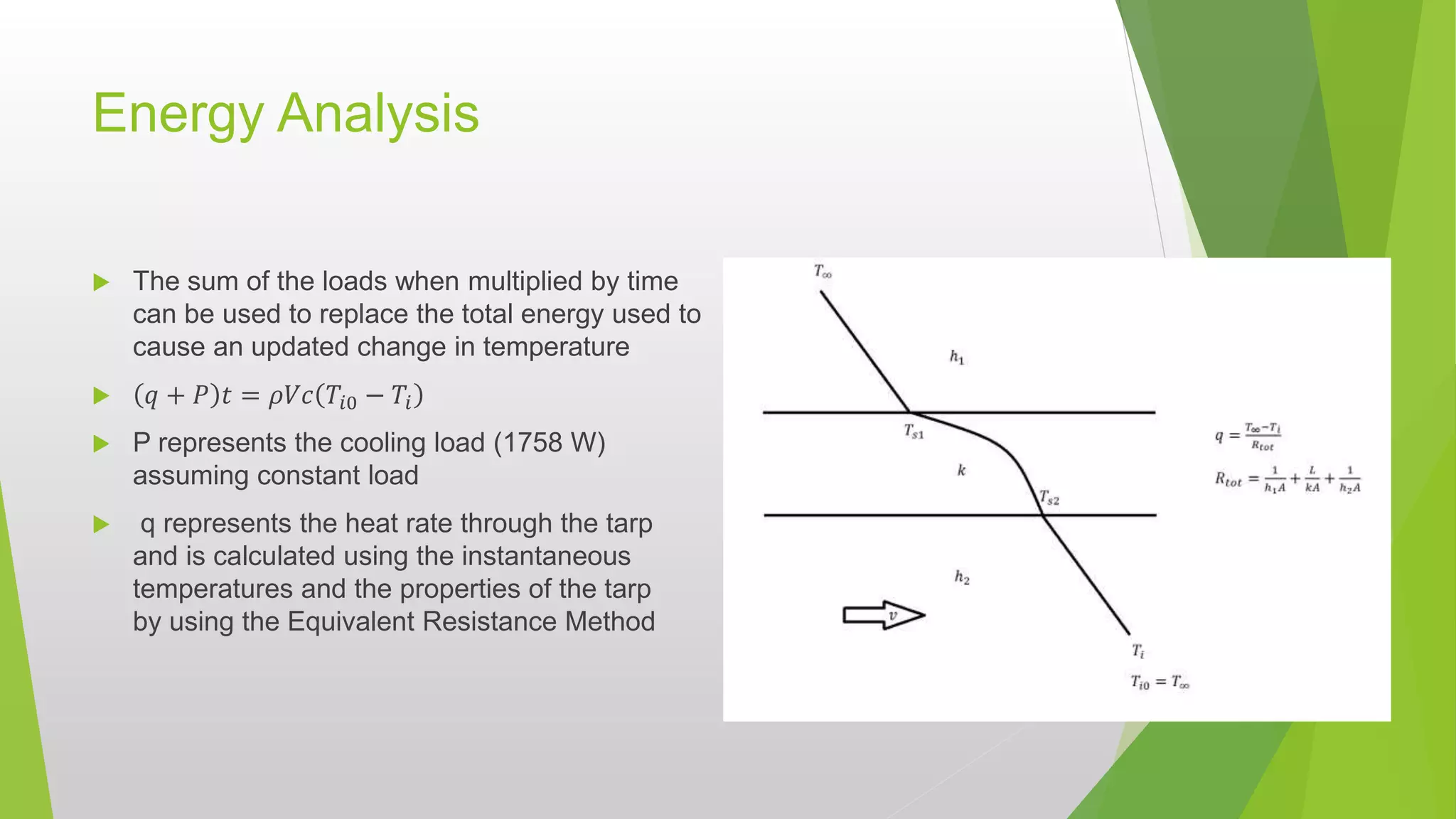

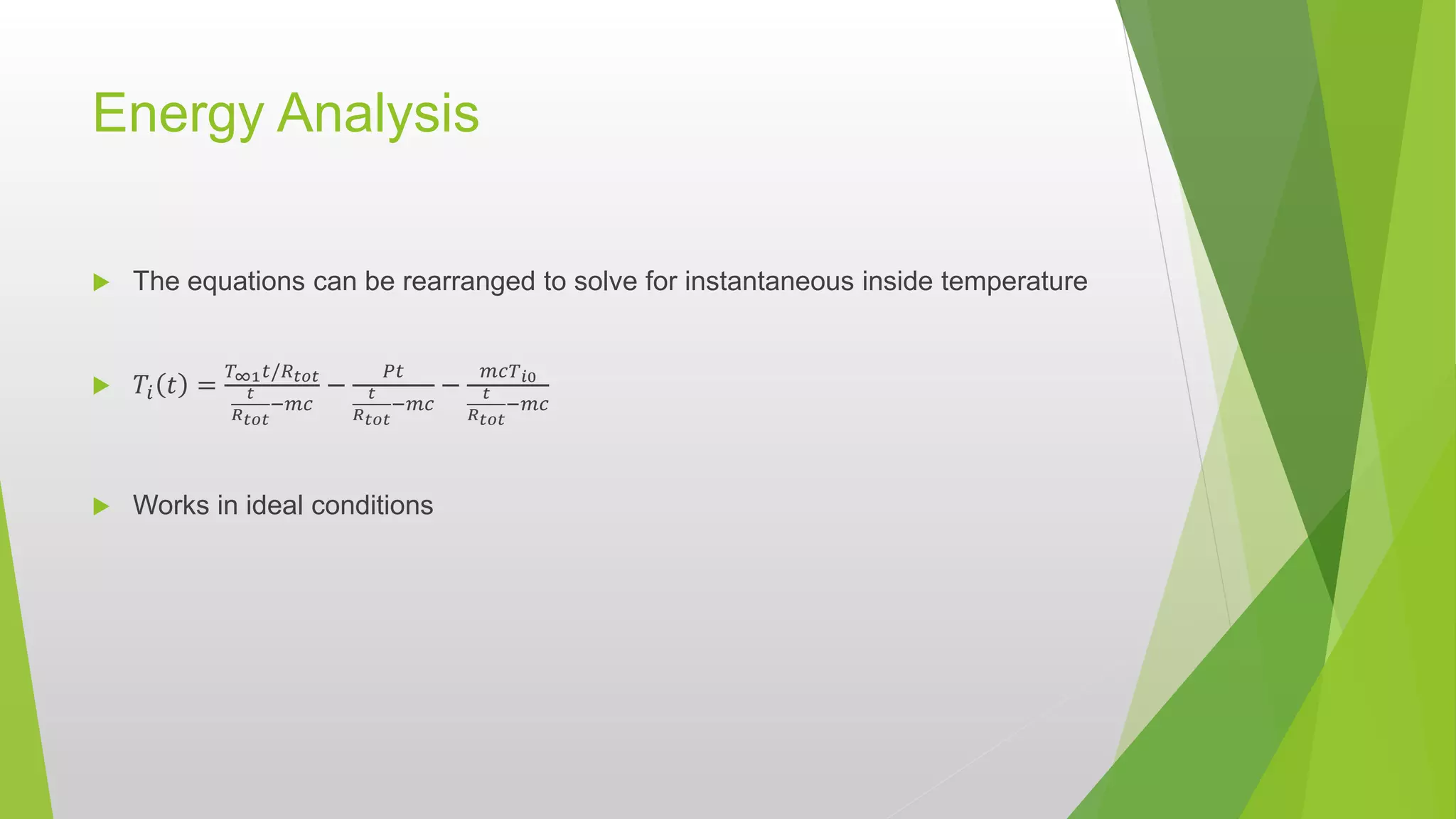

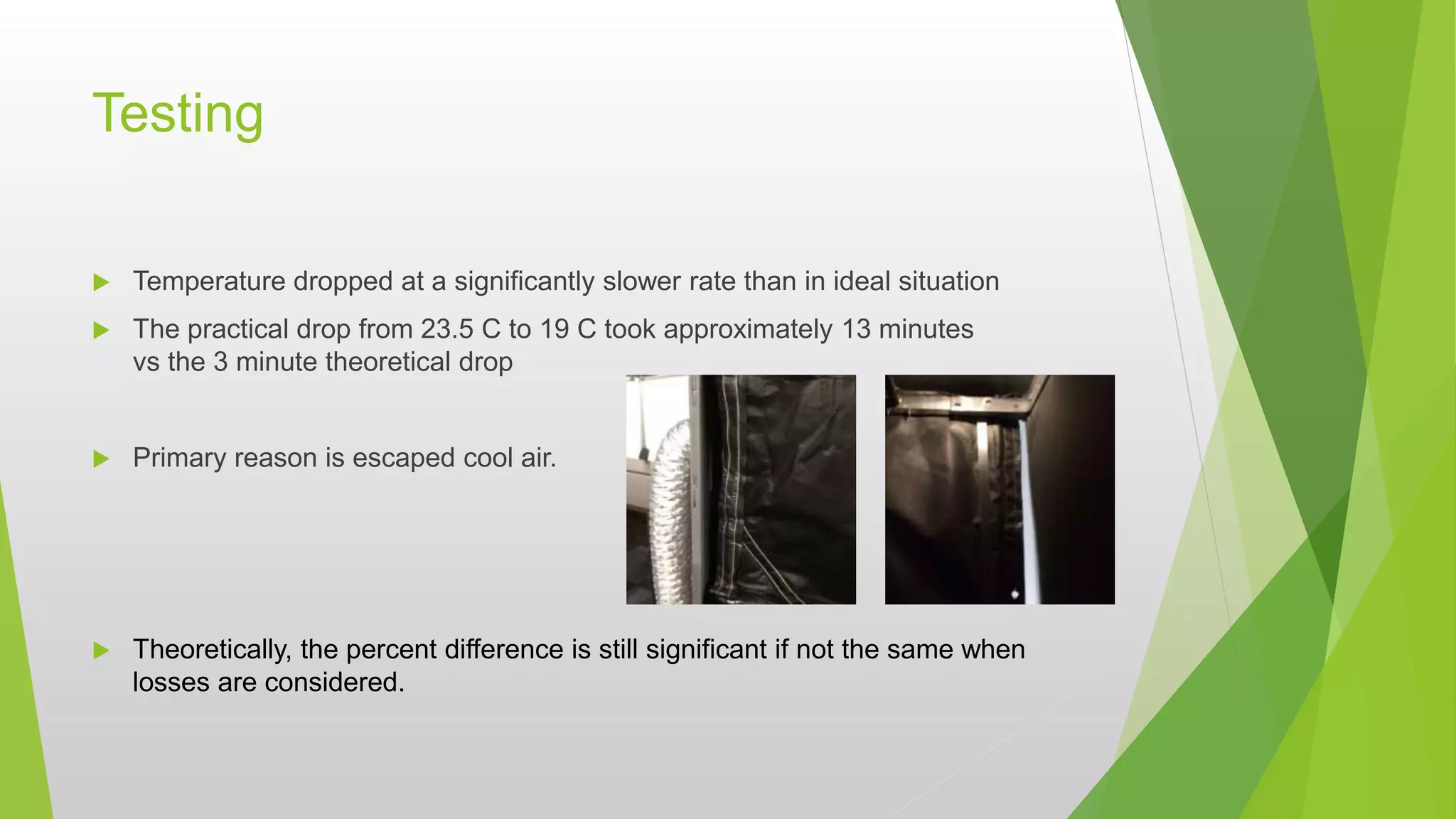

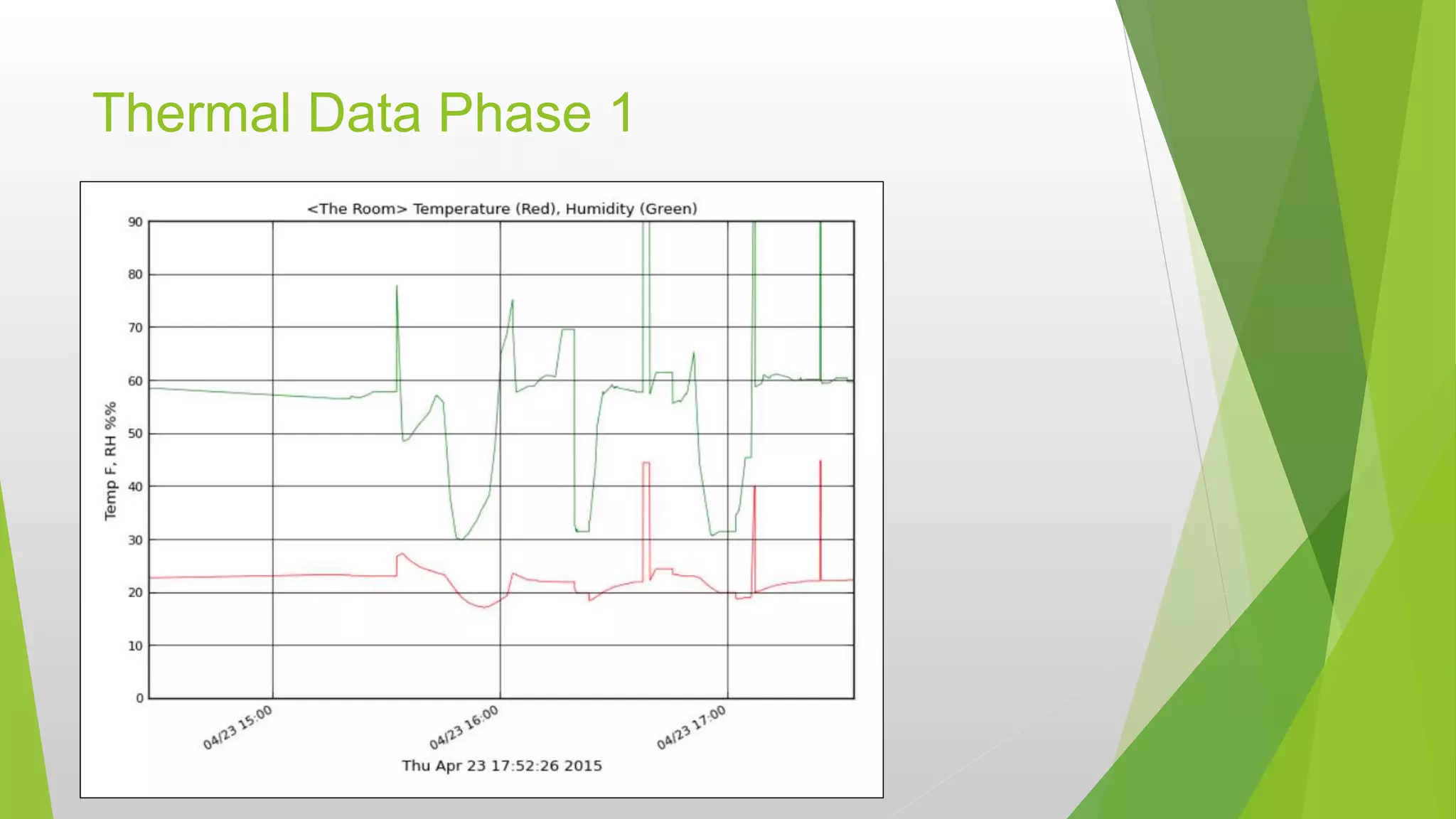

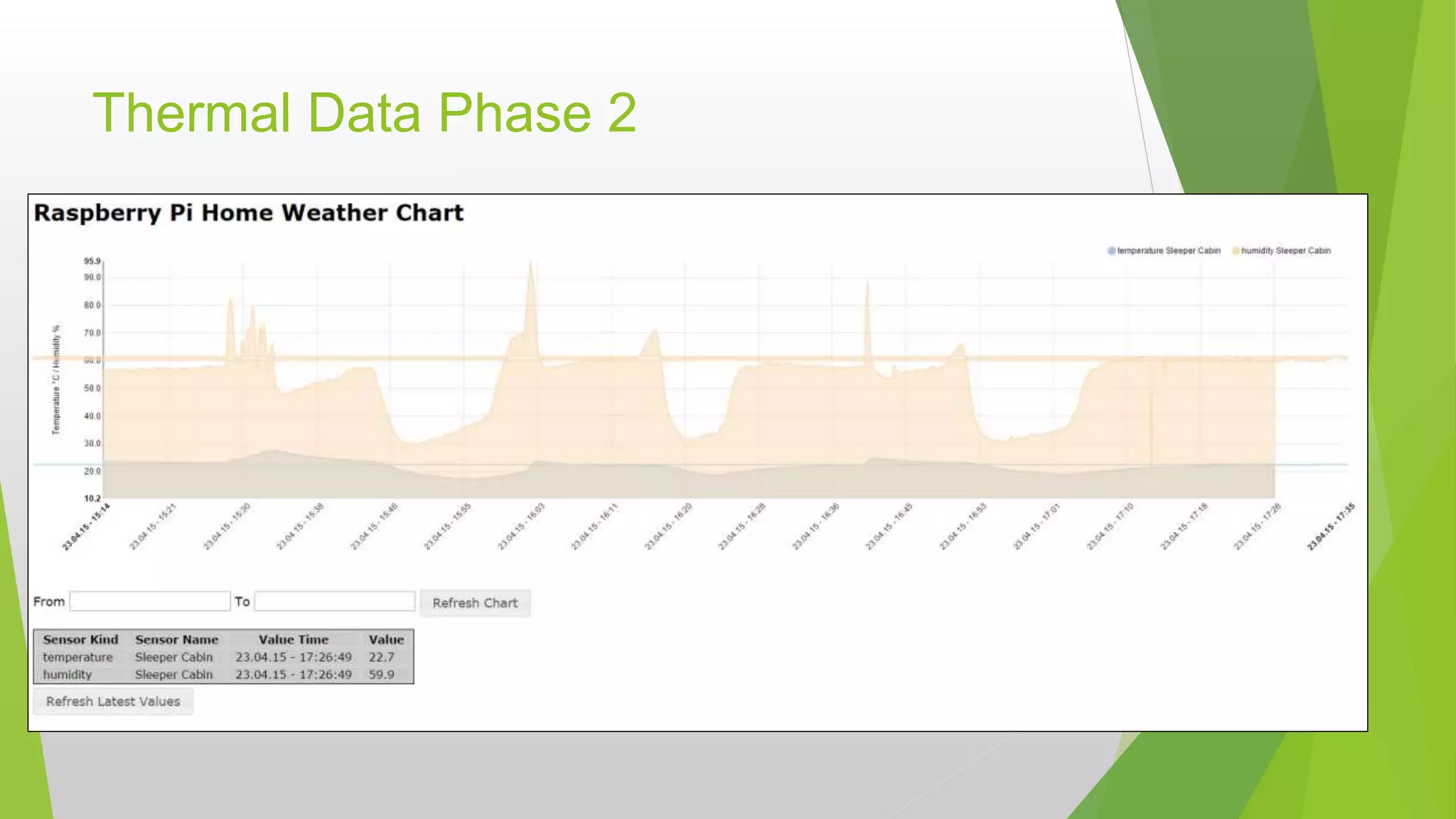

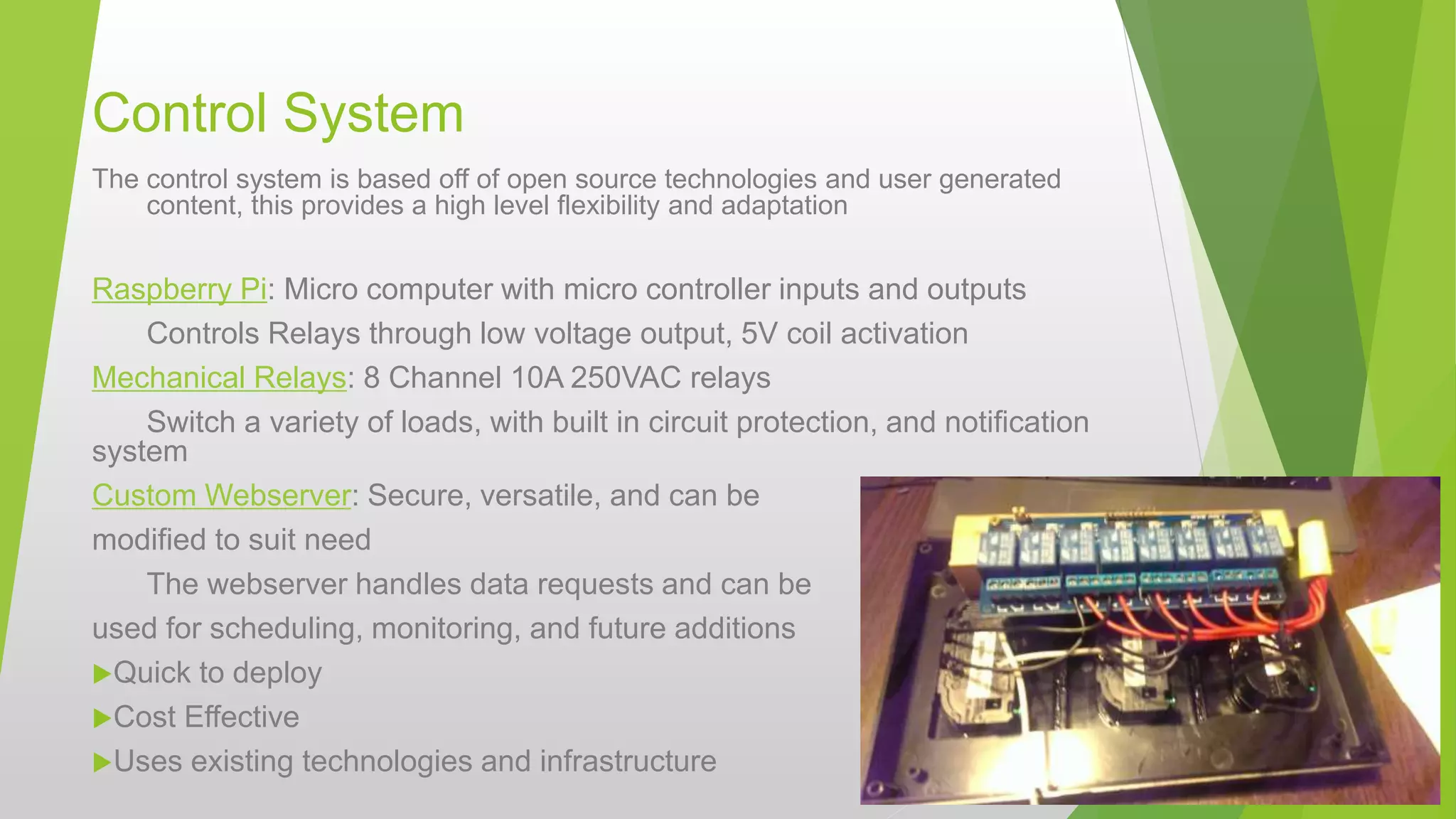

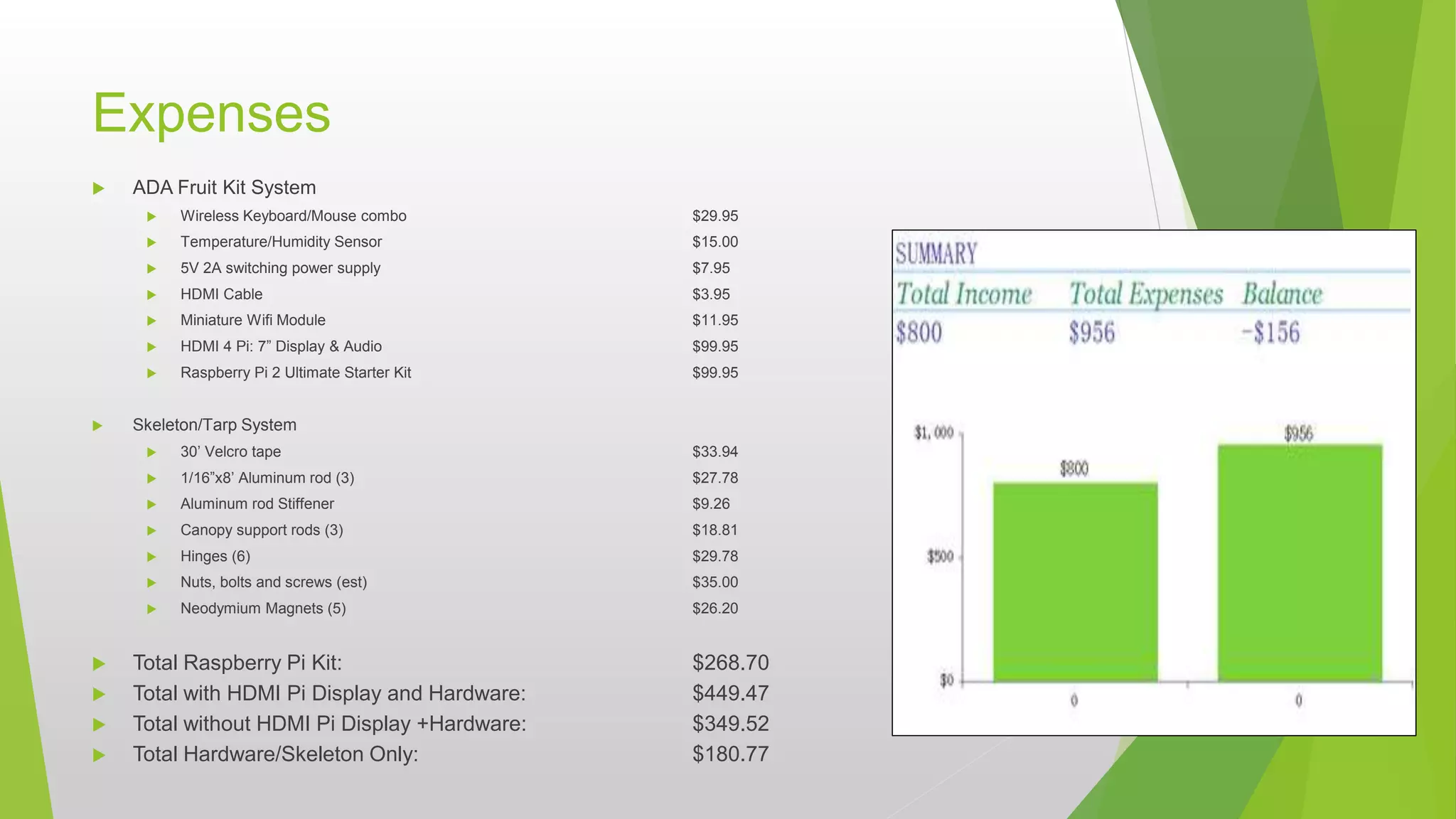

The document describes an isolated air conditioning system for truck sleeper cabs. It aims to reduce fuel costs from idling trucks by containing cooled air more efficiently. The system uses a lightweight aluminum skeleton and insulated tarp to form a canopy over the cab, dramatically reducing the area that needs cooling. It is automated using a Raspberry Pi control system for monitoring and scheduling cooling. Testing showed the canopy lowered temperatures significantly faster than an uncovered cab, with potential for further improvements to airtightness and materials. The goal is to improve driver comfort while cutting fuel usage and emissions.