1) The document summarizes an OEM vendor development project presentation by Electropolymers Pvt. Ltd. for improvements identified with assistance from SMEDA-JICA.

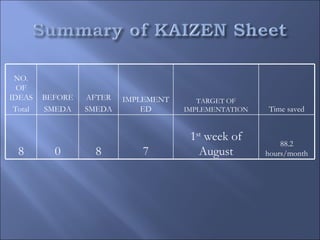

2) A total of 8 improvement ideas were identified and 7 were implemented, resulting in an estimated time savings of 88.2 hours per month.

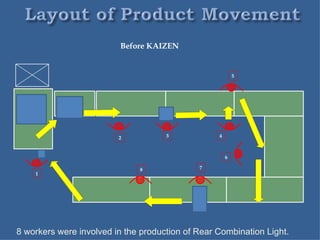

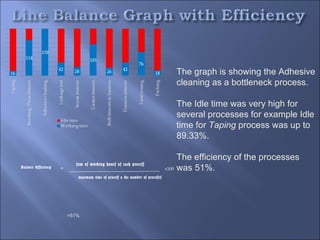

3) The key areas of intervention were productivity improvement and quality improvement for the rear combination lamp, with a focus on reducing cycle time, waste, and costs while improving line efficiency.

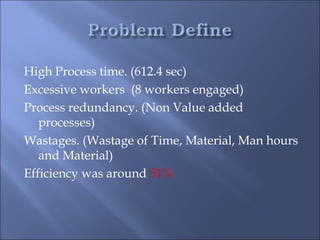

![Process: Sealing Team: Leader: Suggest: SMEDA-JICA

Before (Problem)

1. Possible damage of Hot Melt Nozzle

Because it was installed on the After (Improvement)

passage

2. Possible part defect caused by

Move the Hot Melt Nozzle to inside the process

collision

(other worker)

Date Target (round mark) Status (round mark) Productivity Result

[Before – After (sec/pcs)] x Production Vol.

2012-5-29 Done

Productivity (pcs/mth)

Progressing

Quality, Cost, 5S, Future

NO. Safety, Other_PM (machine protect) Reject Reduced time : 0 hrs./month

1](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-43-320.jpg)

![Mr. Salim / Mr.

Process: Pressing Team: Leader: Suggest: Adnan

Before (Problem) After (Improvement)

Change the upper and lower die and upper

It takes long time to use the press machine.

die fix to the moving plate so that worker can

use

1. The worker has to hold the upper base plate

Both hands for loading and unloading of the

in one hand and put the part from second hand.

parts.

2. Possibility of damaging the part and also it

take long time to perform the operation.

*Shorten the operation time.

*Makes worker task easier.

Date Target (round mark) Status (round mark) Productivity Result

Done [Before – After (sec/pcs)] x Production Vol.

2012-6-5 (pcs/mth)

Productivity Progressing

(37-20)sec/pcs x 3600pcs/month= 61200

Quality, Cost, 5S, Future sec/month

NO. Safety, Other(_____________) Reject

2 Reduced time : 17 hrs./month](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-44-320.jpg)

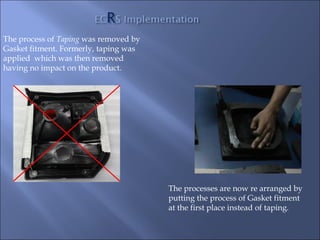

![Process: Team: Leader: Suggest: Mr. Salim

Before (Problem) After (Improvement)

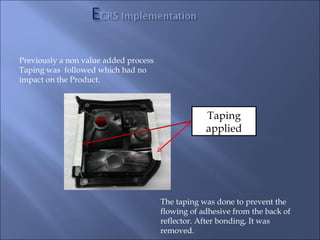

Sealing performed after application of Rearrange the process and eliminate

masking tape on every part “Waste of process itself”

*Take much time to masking & remove it *Eliminate Waste process (application of

“Waste of process itself” masking tap)

*Reduce working time

*Waste of masking tape *No masking tape required (cost reduction)

Before

1.Sealing After

1.Gasket fitment

2.Bonding/Press 2.Bonding/Press

fitment fitment

Masking

3.Adhesive cleaning 3.Adhesive cleaning

tape

Remove Tape 4.Leakage test

4.Leakage test 5.Screw/ Bulb &

5.Tightening Harness

6.Gasket fitment fitment

7.Assemble harness 6.Final testing +

8.Final testing Packing

9.Packing

Date Target (round mark) Status (round mark) Productivity Result

[Before – After (sec/pcs)] x Production Vol.

2012-6-5 Done

Productivity (pcs/mth)

Progressing

NO. Quality, Cost, 5S, Future (16-0)sec/pcs x 3600pcs/month= 57600sec/month

3 Safety, Other(____Space_________) Reject Reduced time : 16 hrs./month](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-45-320.jpg)

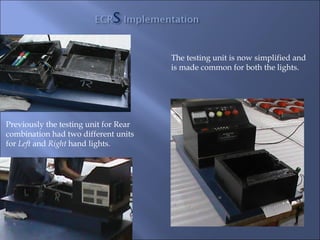

![Process: Leakage Testing Team: Leader: Suggest: Mr. Salim

Before (Problem)

After (Improvement)

1.It takes long time to check the leakage Use low pressure air for check.

2. Possible overlook the water leak Check by bubble

Dip into water and check if water goes into *Shorten the checking time.

the part *Ensure the leakage inspection.

*No water goes into the part (therefore shorten the

cleaning time)

Low Pressure Air

Date Target (round mark) Status (round mark) Productivity Result

[Before – After (sec/pcs)] x Production Vol.

2012-6-10 Done

Productivity (pcs/mth)

Progressing

Quality, Cost, 5S, Future

NO. Safety, Other(_____________)

4 Reject Reduced time : hrs./month](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-46-320.jpg)

![Leader: Suggest: SMEDA-JICA

Process: Gasket Fitment Team:

Before (Problem) After (Improvement)

1-It took long time to perform the operation 1. The idea is to develop a jig with embossed same

Because the glue stick with the workers hand Profile as of gasket and it has little higher with base

and also the gasket stick with card board. so that

2. Make Operator task more difficult. Glue does not stick with base.

2. There will also be location pins as there are holes

Available in the gasket.

It will make the operator work more easy and lesser

time is required.

Location Pins

Jig base

Date Target (round mark) Status (round mark) Productivity Result

[Before – After (sec/pcs)] x Production Vol.

2012-5-29 Done

Productivity (pcs/mth)

Progressing (100.57-79)sec/pcs x 3600pcs/month= 77652 sec/

Quality, Cost, 5S, Future month

NO.

5 Safety, Other(_____________) Reject Reduced time : 21.57 hrs./month](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-47-320.jpg)

![Team: Leader: SMEDA-JICA

Process: Final Testing Suggest:

Before (Problem)

After (Improvement)

There was no proper place for A holder is attached to save the

putting the markers used in time.

marking the parts and there fore

the worker took time in marking.

Date Target (round mark) Status (round mark) Productivity Result

[Before – After (sec/pcs)] x Production Vol.

2012-6-10 Done

Productivity (pcs/mth)

Progressing

Quality, Cost, 5S, Future

NO. Safety, Other(_____________)

6 Reject Reduced time : 0 hrs./month](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-48-320.jpg)

![Team: Leader: SMEDA-JICA

Process: Final Testing Suggest:

Before (Problem)

After (Improvement)

Coupler was fixed in the Jig which was

previously not attached

Date Target (round mark) Status (round mark) Productivity Result

[Before – After (sec/pcs)] x Production Vol.

2012-6-10 Done

Productivity (pcs/mth)

Progressing

Quality, Cost, 5S, Future

NO. Safety, Other(_____________)

7 Reject Reduced time : 0 hrs./month](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-49-320.jpg)

![Process: Team: Leader: Suggest:

Before (Problem) After (Improvement)

Excessive length of bolts

*It take long time to tighten nuts

Date Status (round mark) Productivity Result

Target (round mark)

2012-5-29 [Before – After (sec/pcs)] x Production Vol.

Productivity Done (pcs/mth)

NO. Quality, Cost, 5S, Progressing

0 Safety, Other(_____________) Future Reduced time : hrs./month

Reject](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-52-320.jpg)

![Process: Team: Leader: Suggest:

Before (Problem) After (Improvement)

Date Productivity Result

Target (round mark) Status (round mark) [Before – After (sec/pcs)] x Production Vol.

2012-5-29 (pcs/mth)

Productivity Done

Quality, Cost, 5S, Progressing

NO.

0 Safety, Other(_____________) Future Reduced time : hrs./month

Reject](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-53-320.jpg)

![Process: Team: Leader: Suggest:

Before (Problem) After (Improvement)

Example of

Inadequate lightening for Test lightening at Auto

Assembly Line

*Possible overlook the defects

Dedicate

Lightening for Test

Productivity Result

Date Status (round mark) [Before – After (sec/pcs)] x Production Vol.

Target (round mark)

2012-5-29 (pcs/mth)

Productivity Done

NO Quality, Cost, 5S, Progressing

. Safety, Other(_____________) Future Reduced time : hrs./month

0 Reject](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-54-320.jpg)

![Process: Team: Leader: Suggest:

Before (Problem) After (Improvement)

This worker is just holding Jig (waste of time) Hold the Jig by Clamp or something

Unload lamps one by one (take a long time) Remove the springs one side all then after

remove the other side of spring so that

unloading time will be shortened

Picture or figure

Date Status (round mark) Productivity Result

Target (round mark) [Before – After (sec/pcs)] x Production Vol.

2012-5-29 (pcs/mth)

Productivity Done

NO. Quality, Cost, 5S, Progressing

Safety, Other(_____________) Future Reduced time : hrs./month

0 Reject](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-55-320.jpg)

![Leader: Suggest: SMEDA-JICA

Process: Team:

Before (Problem)

After (Improvement)

Material handling should be improved by

making the trolleys in order to reduce the

risk of damaging.

Date Target (round mark) Status (round mark) Productivity Result

[Before – After (sec/pcs)] x Production Vol.

2012-5-29 Done

Productivity (pcs/mth)

Progressing

Quality, Cost, 5S, Future

NO.

5 Safety, Other(_____________) Reject Reduced time : hrs./month](https://image.slidesharecdn.com/finalpresentation-120716044229-phpapp01/85/Final-Presentation-56-320.jpg)