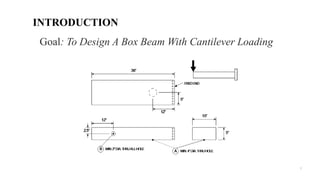

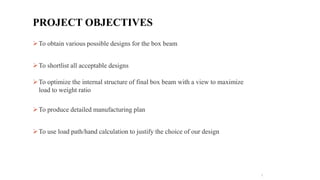

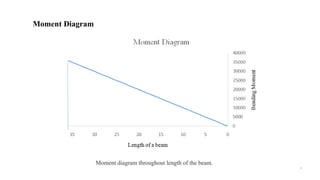

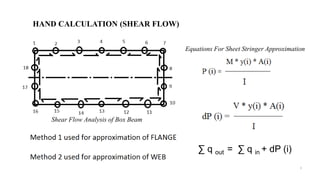

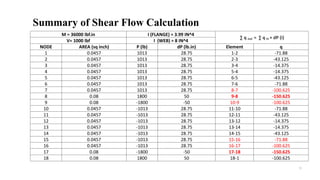

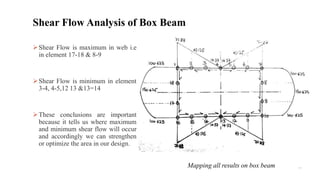

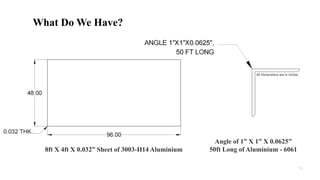

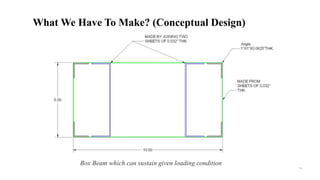

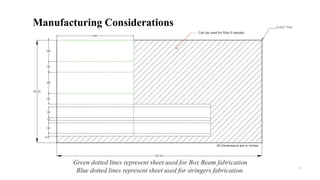

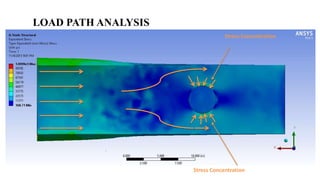

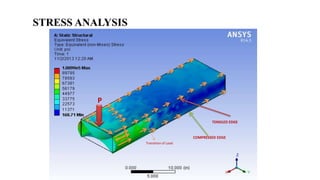

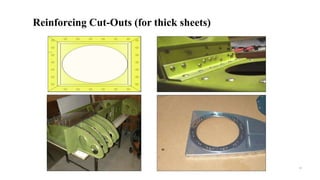

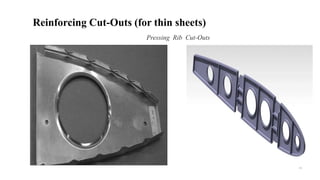

This document summarizes the process of designing and optimizing a box beam for cantilever loading. It outlines the goals of obtaining multiple design options, shortlisting acceptable designs, and optimizing the final design to maximize load to weight ratio. It then describes analyzing shear flow using calculations, considering manufacturing factors for the conceptual designs, and mapping stress concentrations and load path analysis. The document concludes that the final design will be chosen based on efficiency, weight, and manufacturability.