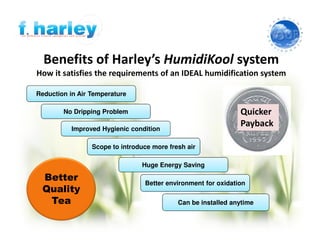

- The document describes Harley's HumidiKool system for humidification and cooling in tea manufacturing facilities.

- It maintains 1-2 degree C temperature difference between dry and wet conditions while providing 90-95% relative humidity, optimizing ambient cooling.

- The system uses high pressure fog nozzles to generate ultra fine 5 micron water droplets that absorb latent heat and lower air temperature while maintaining uniform humidity.

- It provides more efficient humidification and cooling than traditional spot humidifiers or ducting systems while using less energy and space.