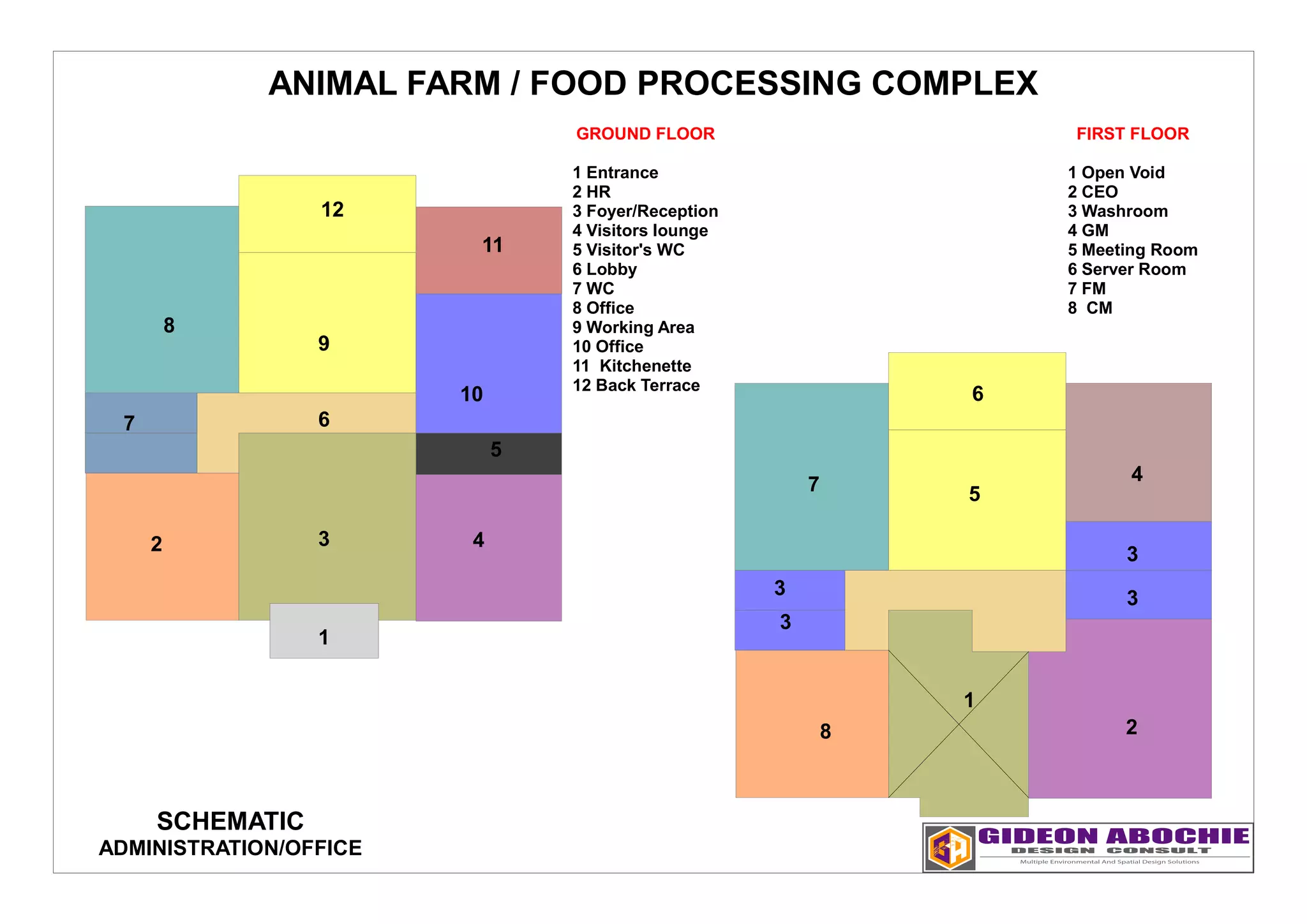

This document provides plans and information for an animal farm and food processing complex. It includes a basic block plan showing the layout of the various facilities on the property. The main areas of the abattoir or slaughterhouse are described, including stockyards, lairage areas for holding animals, and sections for stunning, bleeding, carcass dressing, inspection, and washing. Diagrams depict the flow of clean and dirty areas as well as the standard layout of a slaughterhouse and the administration office floors. The goal is to humanely process animals into meat in a sanitary and regulated manner.