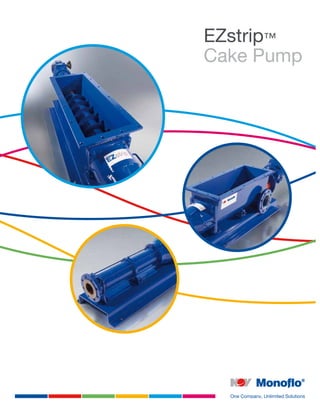

The document introduces the ezstrip cake pump with an innovative design facilitating easy maintenance without the need for disconnecting pipes, enabling maintenance in as little as 6 minutes. Key features include a detachable feed chamber for quick access, and the pump's capability to handle high solid contents, making it efficient for sludge treatment and dewatering applications. It emphasizes reduced downtime and labor costs, highlighting its suitability for various sludge blending and transfer processes.