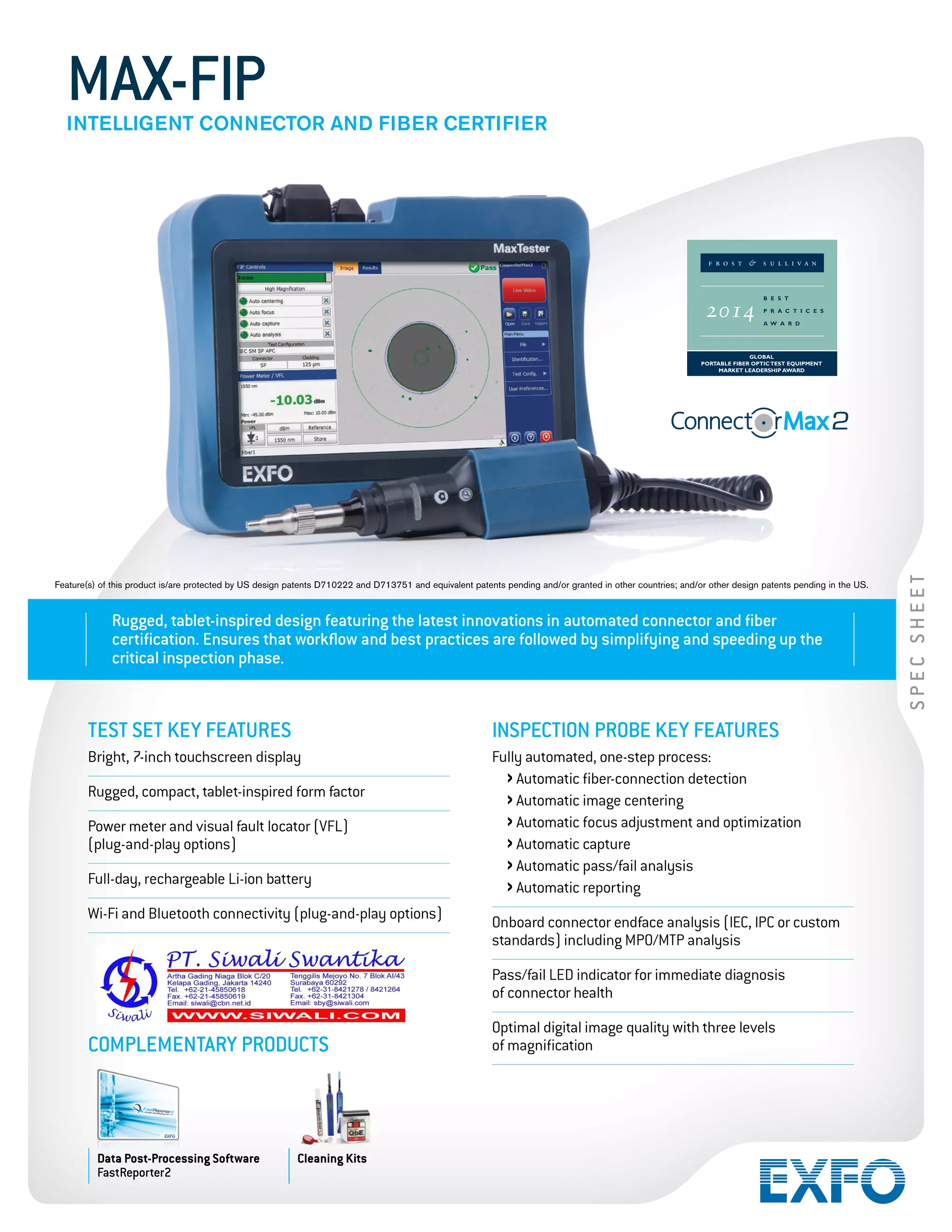

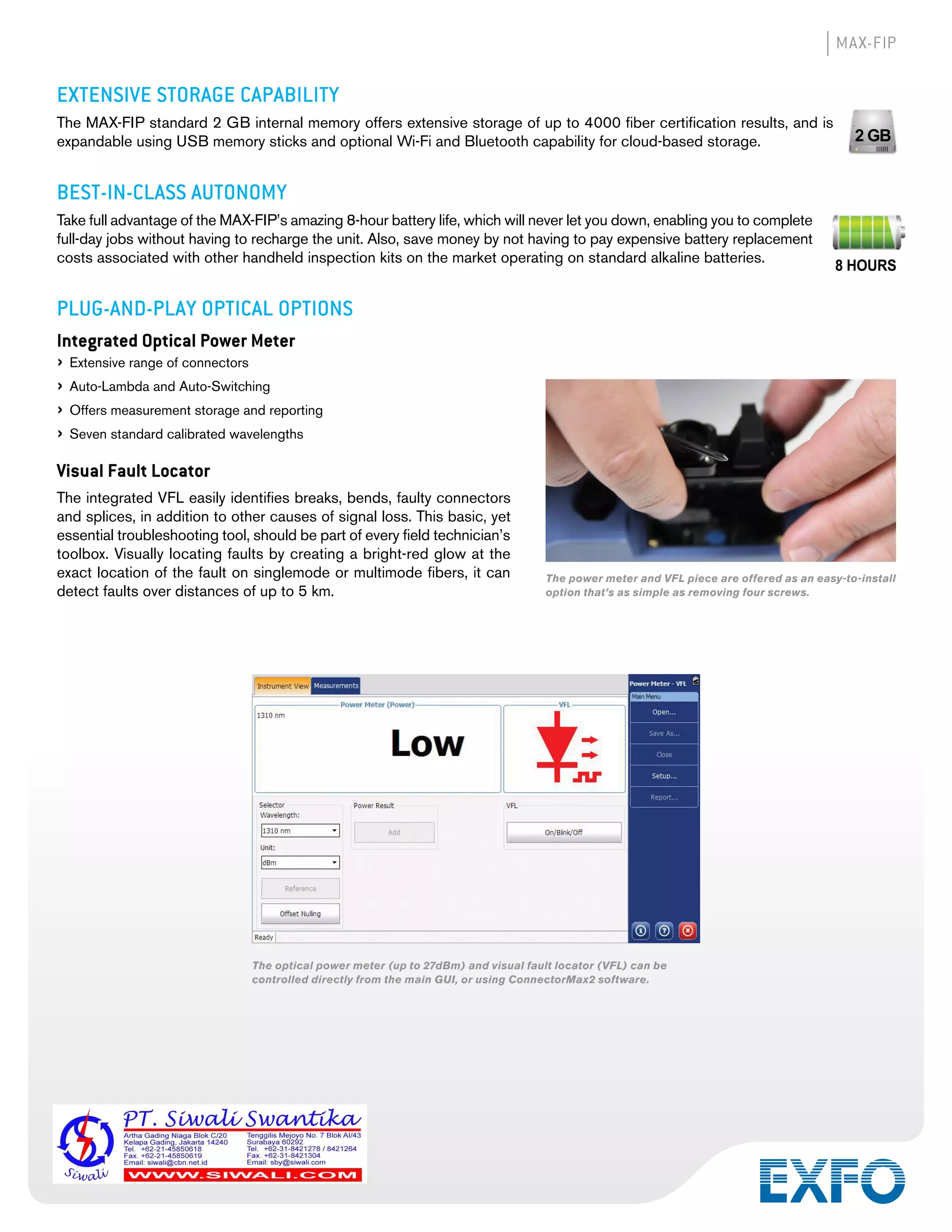

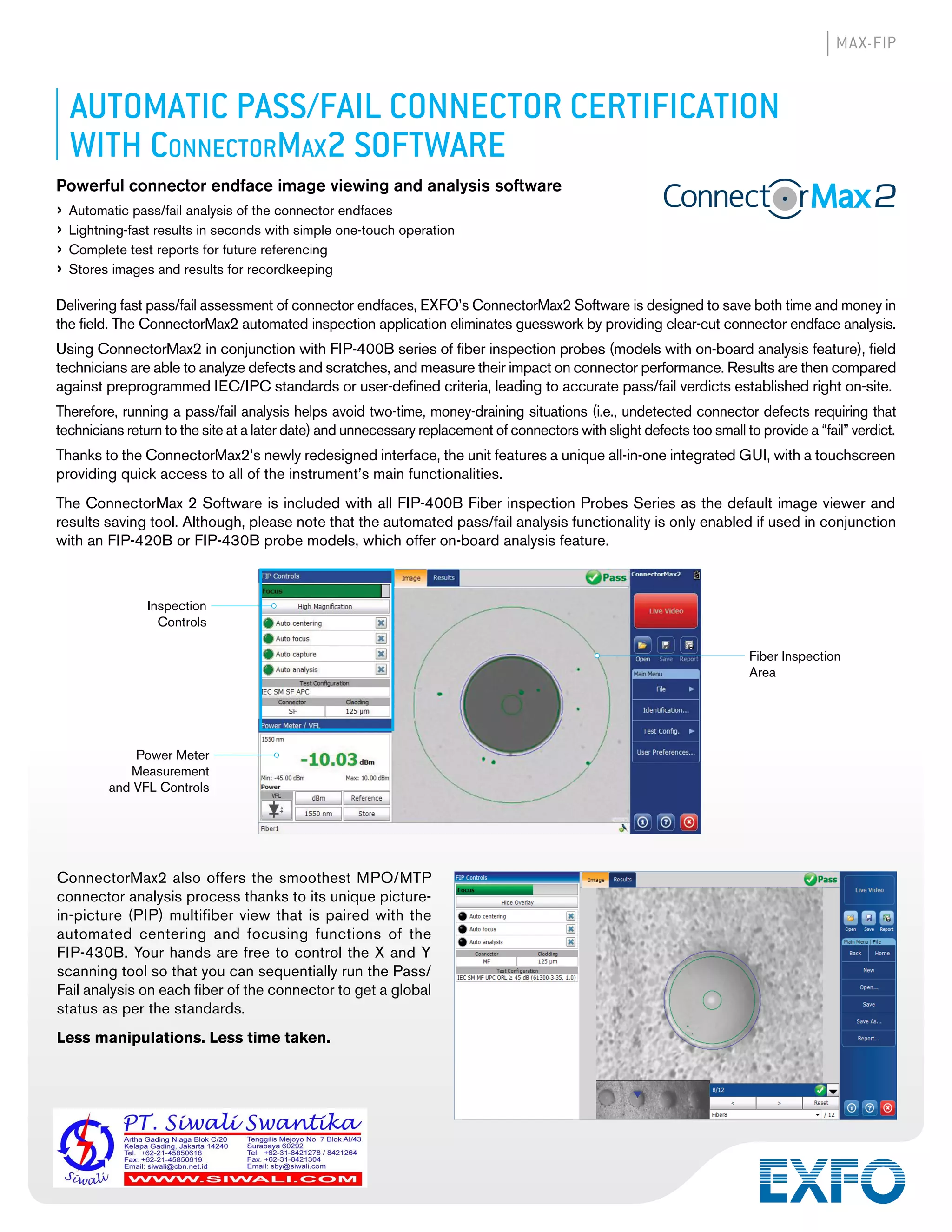

The document outlines the specifications and features of the max-fip fiber inspection system, which includes a rugged, tablet-inspired design, a 7-inch touchscreen, and automated inspection capabilities for enhanced fiber certification. Key functionalities include automatic focus adjustment, pass/fail analysis, and connectivity options, supported by the Connectormax2 software for efficient data management. The product aims to improve inspection workflows, reduce failure rates, and provide significant cost savings in fiber network maintenance.