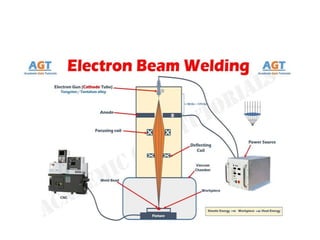

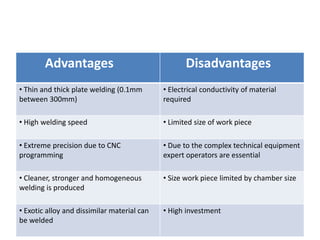

Electron beam welding is a fusion welding process that uses a stream of high-speed electrons generated by an electron gun and accelerated using electrical fields to melt and join materials. The electron beam is tightly focused using magnetic fields onto the materials to be welded. It allows for welding of thin to thick plates from 0.1mm to 300mm thick and offers advantages like high welding speed, precision, cleaner welds, and ability to weld exotic alloys or dissimilar materials. However, it has limitations like requiring electrically conductive materials and expertise to operate complex equipment.